Preparation technology of fully synthetic cutting fluid

A preparation process, cutting fluid technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of unhealthy workers, diluent foam, easy to decompose and other problems, to achieve not suitable for corruption, long indoor storage period, cleaning performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

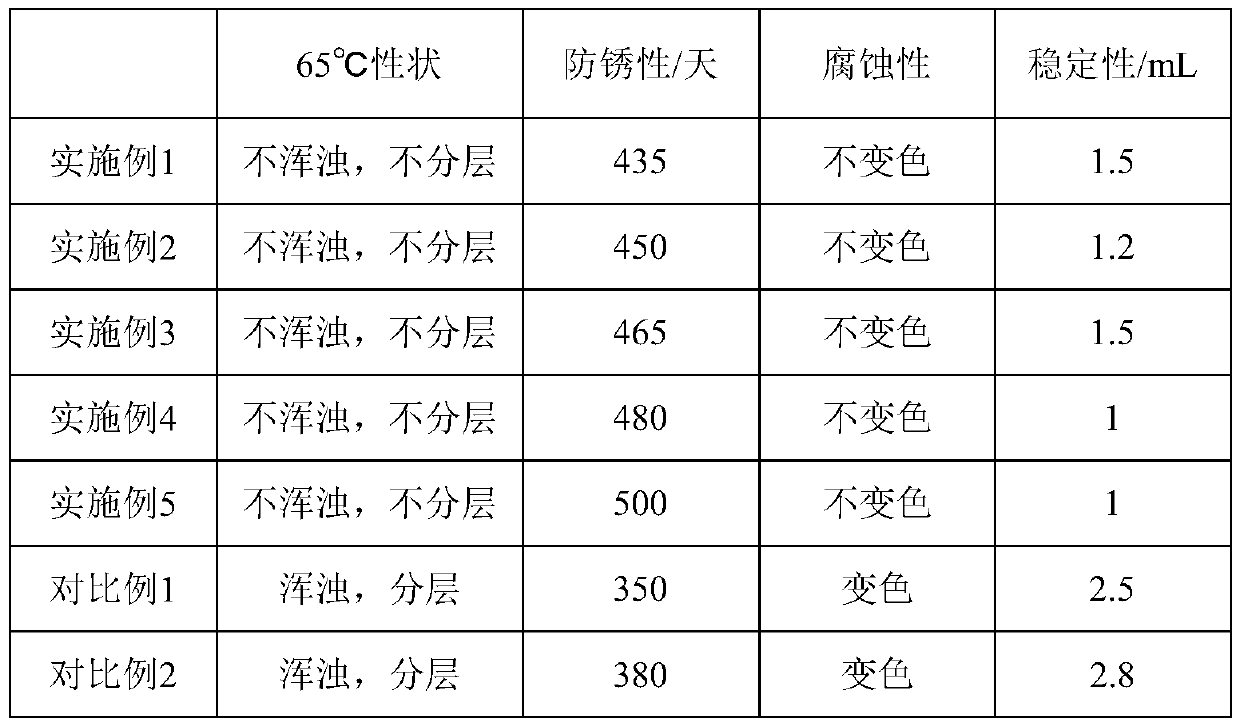

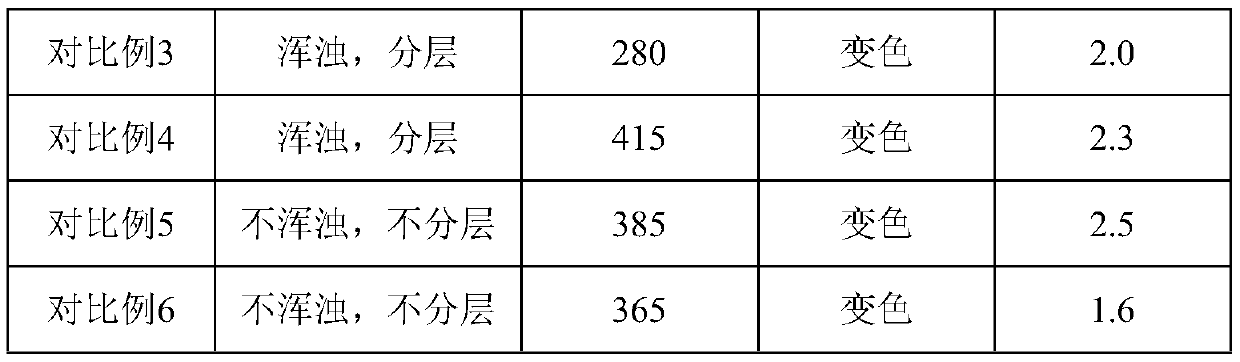

Examples

Embodiment 1

[0068] Embodiment 1 provides a kind of preparation process of fully synthetic cutting fluid, and the steps include:

[0069] (1) Weigh triethanolamine and its derivatives into water, heat and stir until uniform, and the heating temperature is 50°C;

[0070] (2) Add antirust agent and oleic acid to the mixture of step (1) while stirring, and then add Swire oil and glycerin;

[0071] (3) Add the antibacterial agent to the mixture in step (2) and stir evenly, after cooling to room temperature, the material can be discharged.

[0072] The fully synthetic cutting fluid includes the following components in parts by weight: 5 parts of triethanolamine and its derivatives, 3 parts of antirust agent, 1 part of ancient oil, 2 parts of glycerin, 1 part of oleic acid, and 0.5 parts of antibacterial agent , 40 parts of water.

[0073] The triethanolamine and its derivatives are obtained by compounding triethanolamine and triethanolamine borate at a weight ratio of 2.5:1.

[0074] Describ...

Embodiment 2

[0083] Embodiment 2 provides a kind of preparation process of fully synthetic cutting fluid, and the steps include:

[0084] (1) Weigh triethanolamine and its derivatives into water, heat and stir until uniform, and the heating temperature is 35°C;

[0085] (2) Add antirust agent and oleic acid to the mixture of step (1) while stirring, and then add Swire oil and glycerin;

[0086] (3) Add the antibacterial agent to the mixture in step (2) and stir evenly, after cooling to room temperature, the material can be discharged.

[0087] The fully synthetic cutting fluid includes the following components in parts by weight: 15 parts of triethanolamine and its derivatives, 10 parts of antirust agent, 7 parts of ancient oil, 8 parts of glycerin, 6 parts of oleic acid, and 3 parts of antibacterial agent , 70 parts of water.

[0088] The triethanolamine and its derivatives are obtained by compounding triethanolamine and triethanolamine borate at a weight ratio of 3.5:1.

[0089] Descr...

Embodiment 3

[0095]Embodiment 3 provides a kind of preparation process of fully synthetic cutting fluid, and the steps include:

[0096] (1) Weigh triethanolamine and its derivatives into water, heat and stir until uniform, and the heating temperature is 40°C;

[0097] (2) Add antirust agent and oleic acid to the mixture of step (1) while stirring, and then add Swire oil and glycerin;

[0098] (3) Add the antibacterial agent to the mixture in step (2) and stir evenly, after cooling to room temperature, the material can be discharged.

[0099] The fully synthetic cutting fluid includes the following components in parts by weight: 8 parts of triethanolamine and its derivatives, 5 parts of antirust agent, 3 parts of ancient oil, 3 parts of glycerin, 2 parts of oleic acid, and 1 part of antibacterial agent , 45 parts of water.

[0100] The triethanolamine and its derivatives are obtained by compounding triethanolamine and triethanolamine borate at a weight ratio of 3:1.

[0101] Described a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com