Preparation method of phosphorus-doped cadmium sulfide supported nickel carbide quantum-dot nanorod photocatalyst

A photocatalyst and nanorod technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor stability and visible light catalytic activity, affecting the application of photocatalysts, etc., to achieve strong visible light Responsiveness, good development potential, excellent stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

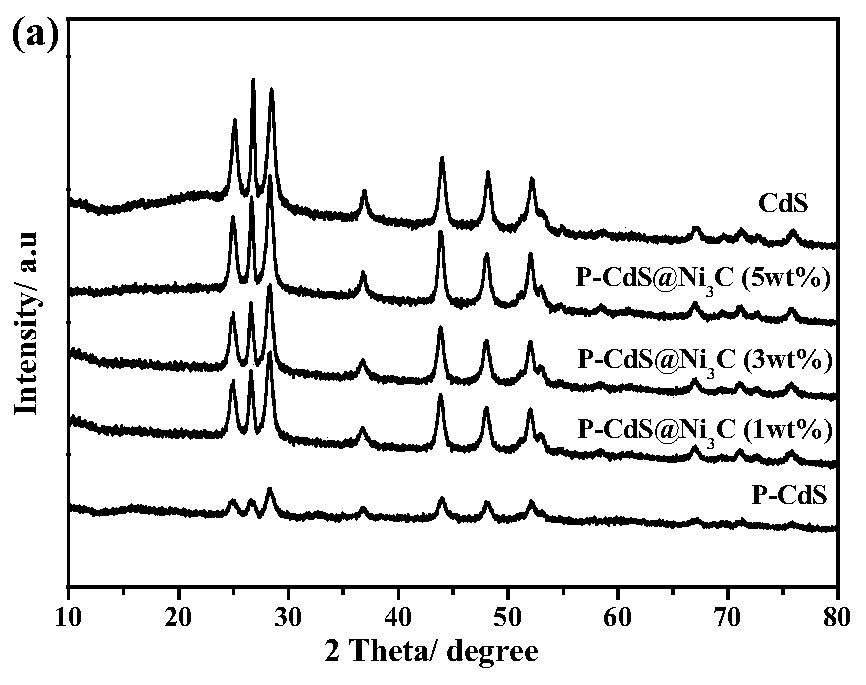

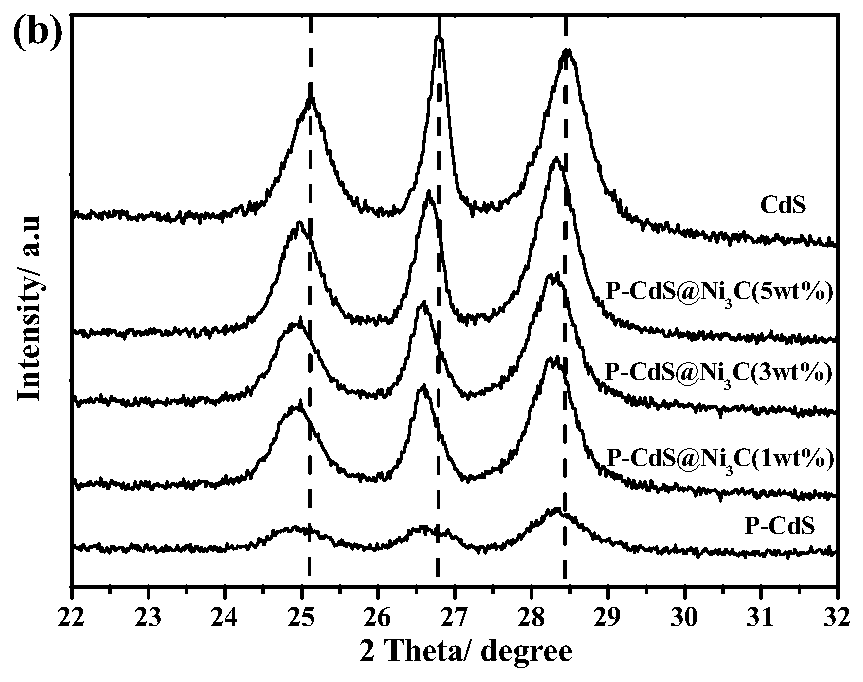

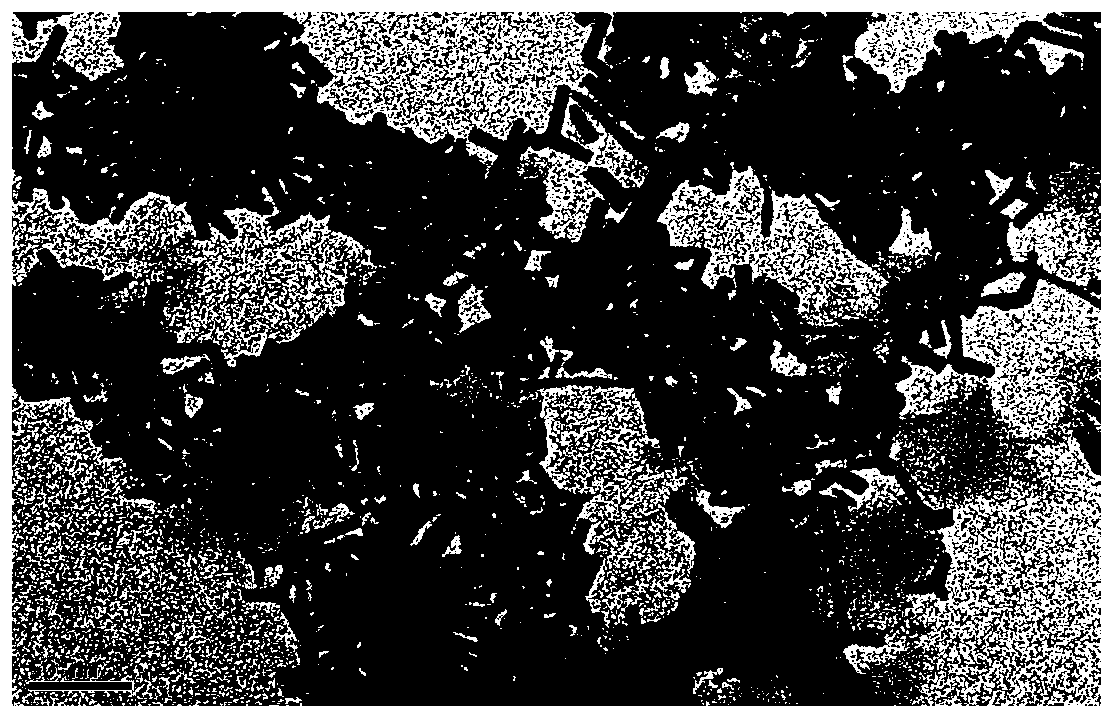

[0028] The preparation process of CdS nanorods is as follows:

[0029] Add 3.0-5.0g of trioctylphosphine oxide, 0.60-1.0g of n-octadecyl phosphate and 0.10-0.5g of cadmium oxide into the three-necked flask, heat it to 300-350°C under vacuum, and keep it for 1 hour , to dissolve CdO, then inject 3.3g of monomeric tri-n-octylphosphine (TOP) and 0.1g of sulfur powder, react under a nitrogen atmosphere, then cool to 70°C, and finally add 3-6mL of toluene to initially remove the surface Active agent, and finally ultrasonically washed with a mixture of toluene and acetone to remove the surfactant, and then dried in an oven at 60°C for 5 hours to obtain CdS nanorods, wherein the volume ratio of toluene to acetone is 1:1, and the molar ratio of CdO to sulfur powder The ratio is 1 to 3-10.

[0030] The preparation method of phosphorus-doped cadmium sulfide loaded nickel carbide quantum dot nanorod photocatalyst of the present invention comprises the following steps:

[0031] 1) Take ...

Embodiment 1

[0036] The preparation method of phosphorus-doped cadmium sulfide loaded nickel carbide quantum dot nanorod photocatalyst of the present invention comprises the following steps:

[0037] 1) Take CdS nanorods and NaH 2 PO 2 , and then CdS nanorods and NaH 2 PO 2 mixed and then in N 2 Heating to 500°C in the atmosphere for 10 hours to obtain phosphorus-doped CdS nanorods;

[0038] 2) Dissolve phosphorus-doped CdS nanorods in N,N-dimethylformamide, and then add Ni(NO 3 ) 2 ·6H 2 O and 2-methylimidazole, and then stirred at room temperature for 4h to obtain the precursor material;

[0039] 3) Place the precursor material obtained in step 2) in a polytetrafluoroethylene-lined stainless steel autoclave, heat it to 160°C, and keep it for 24 hours, then cool it to room temperature, and then wash it with deionized water and ethanol , to obtain a black-green product, and place the black-green product in an oven at 60° C. to dry for 12 hours to obtain a phosphorus-doped cadmium s...

Embodiment 2

[0042] The preparation method of phosphorus-doped cadmium sulfide loaded nickel carbide quantum dot nanorod photocatalyst of the present invention comprises the following steps:

[0043] 1) Take CdS nanorods and NaH 2 PO 2 , and then CdS nanorods and NaH 2 PO 2 mixed and then in N 2 Heating to 500°C in the atmosphere for 10 hours to obtain phosphorus-doped CdS nanorods;

[0044] 2) Dissolve phosphorus-doped CdS nanorods in N,N-dimethylformamide, and then add Ni(NO 3 ) 2 ·6H 2 O and 2-methylimidazole, and then stirred at room temperature for 4h to obtain the precursor material;

[0045] 3) Place the precursor material obtained in step 2) in a polytetrafluoroethylene-lined stainless steel autoclave, heat it to 160°C, and keep it for 24 hours, then cool it to room temperature, and then wash it with deionized water and ethanol , to obtain a black-green product, and place the black-green product in an oven at 60° C. to dry for 12 hours to obtain a phosphorus-doped cadmium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com