Condensation type purification system applied to tail end of industrial electric precipitator

A technology of electrostatic precipitator and purification system, applied in the direction of external electrostatic separator, electrostatic separation, electrostatic effect separation, etc., can solve the problems of no purification and removal, low performance of electrostatic precipitator, etc., to improve dust collection performance and eliminate droplets Emissions, flue gas and dust concentration relaxed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

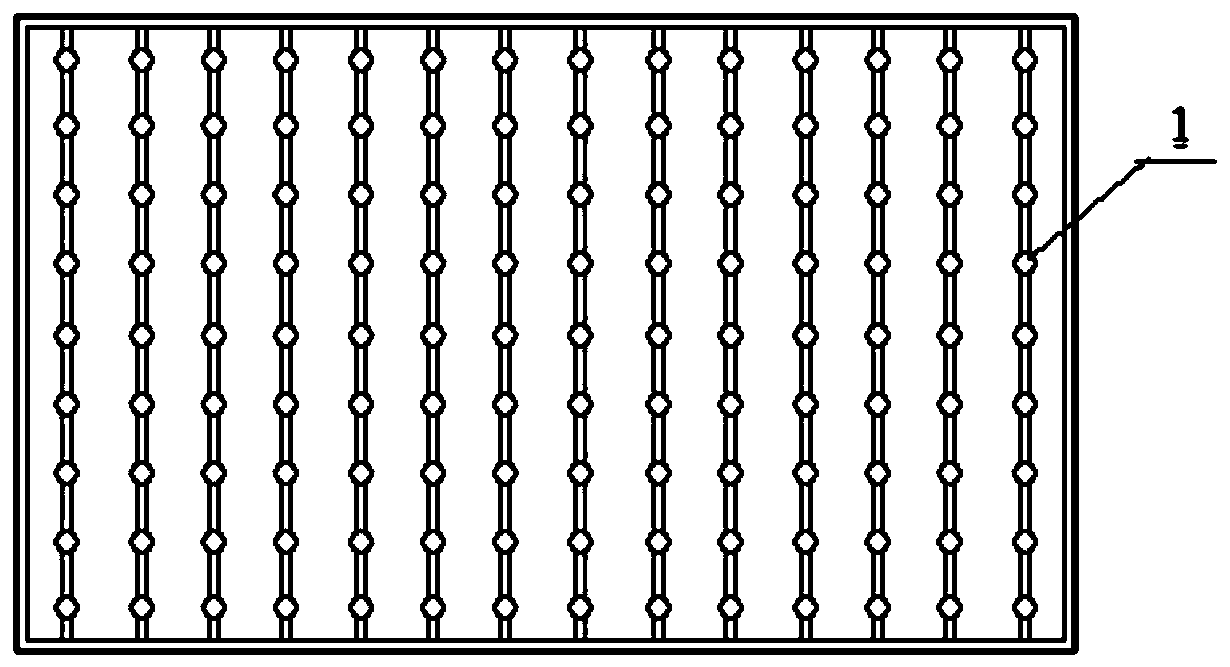

[0029] figure 1 It is a schematic diagram of the frame of the atomized water nozzle, and N atomized water nozzles (1) are installed on the frame with spacing, parallel and uniform distribution.

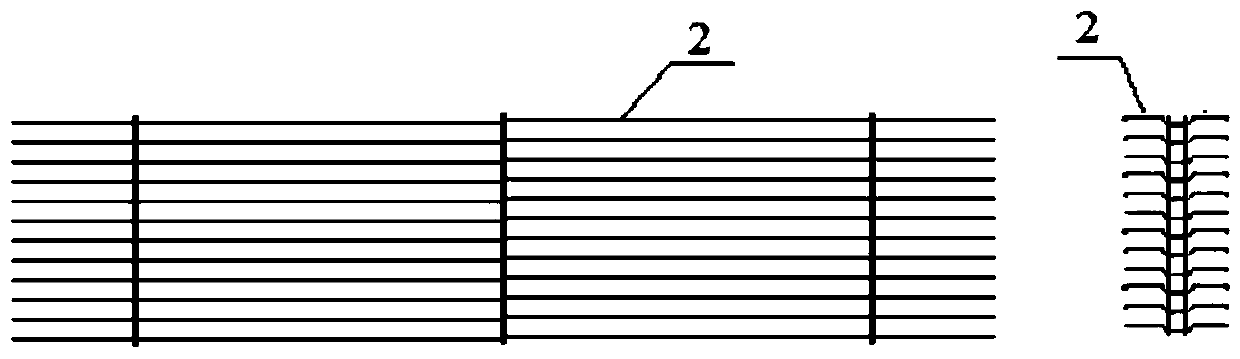

[0030] figure 2 It is a schematic diagram of the structure of the combined defogging and wind extinguishing plate. The structure of this combined defogging and wind extinguishing plate (2) is the same as (a combined defogging and wind extinguishing plate, patent number: 200610046005.3). It is to install and combine the strip plates according to a certain angle, spacing and parallel arrangement.

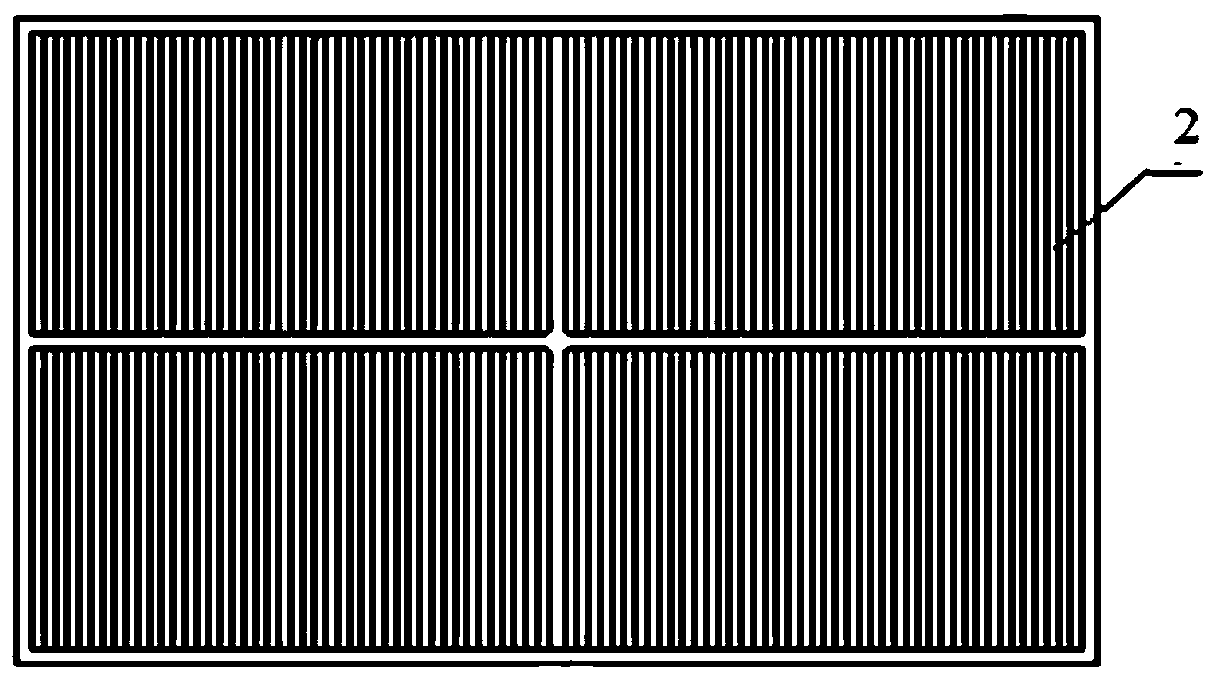

[0031] image 3 It is a schematic diagram of the frame of the combined defogging and wind extinguishing plate, and N combined defogging and wind extinguishing plates (2) arranged vertically, at intervals and in parallel are arranged and fixed on the frame.

[0032] Figure 4 It is a schematic diagram of a corona wire frame, and N cathode corona wires (3) arranged vertically, at interval...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap