An Indium Wire Cutting Device Used for Sealing of Low Temperature Accumulator

A technology of cutting device and pressure accumulator, which is applied in the field of indium wire cutting device, can solve the problems of large cross-section deformation, uneven cross-section, uneven cross-section of indium wire, etc., and achieve the effect of meeting the needs of low-temperature sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

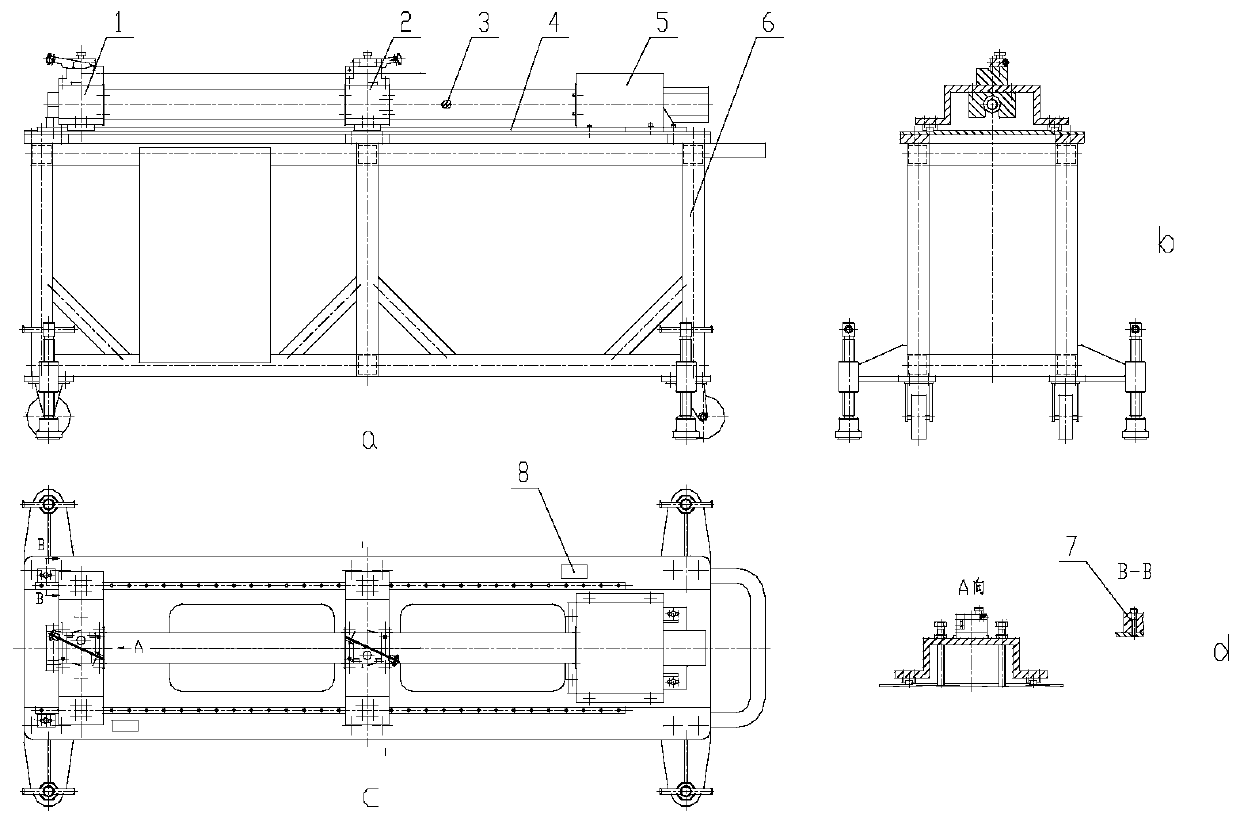

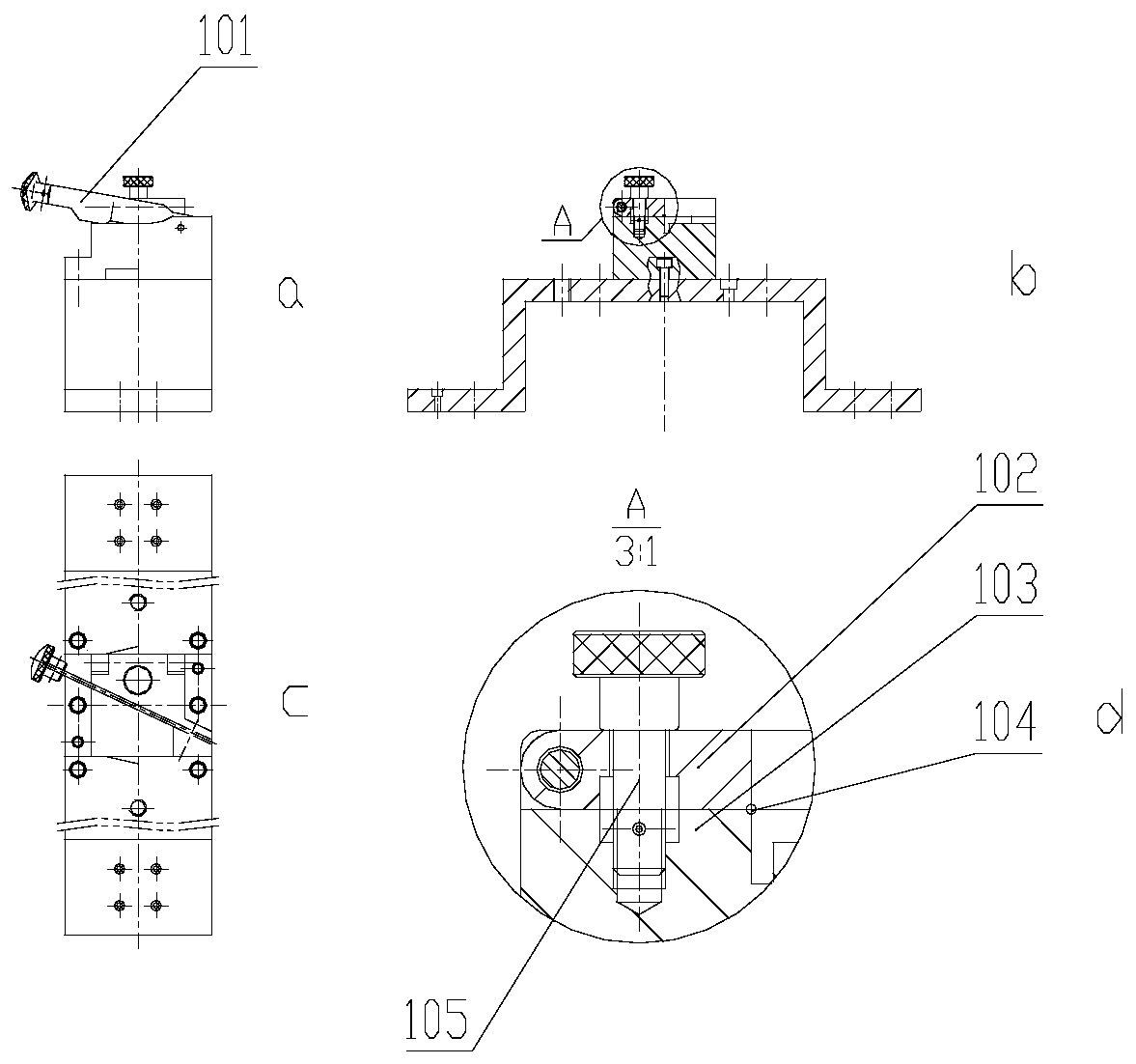

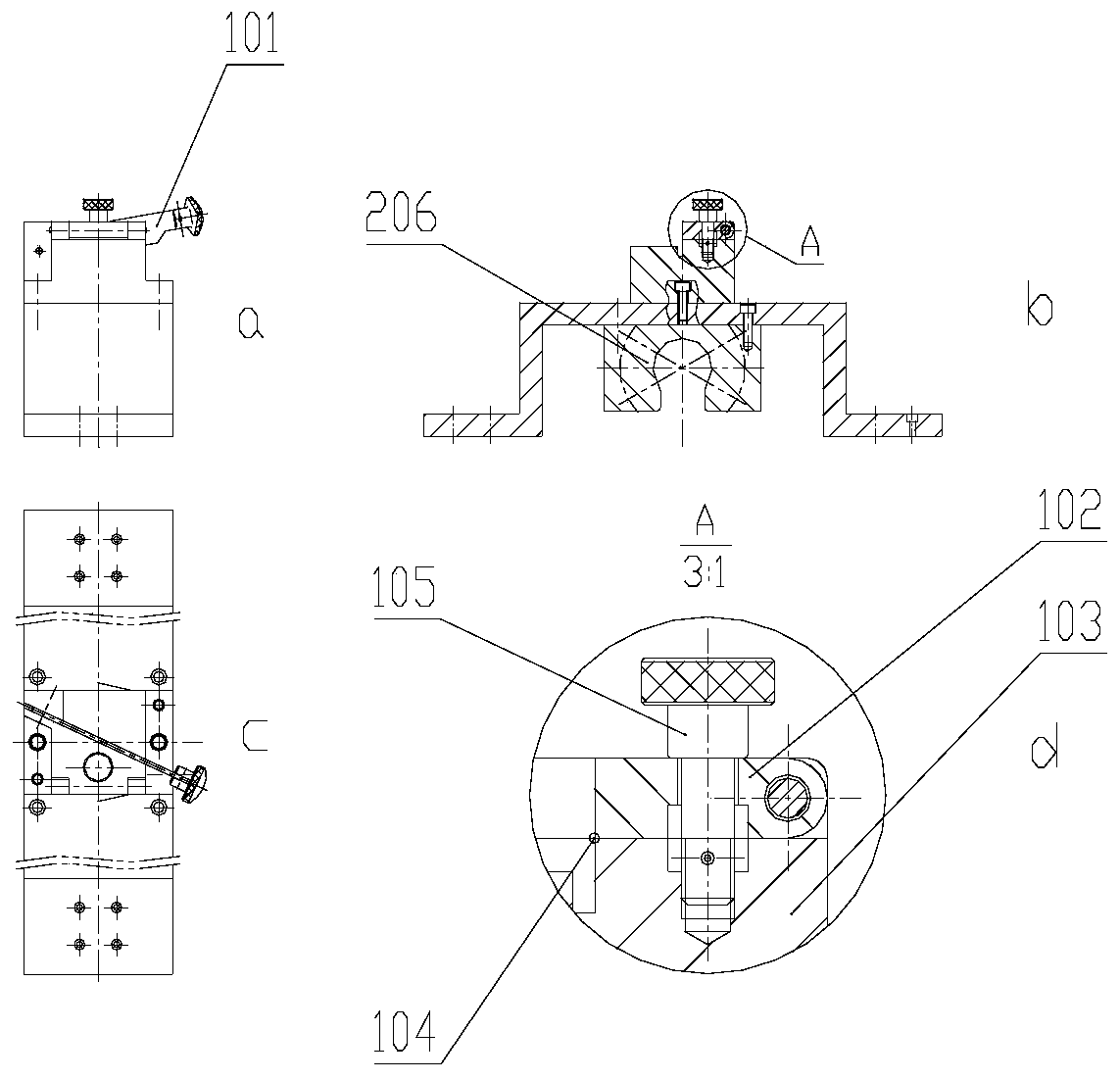

[0024] An indium wire cutting device for cryogenic pressure accumulator seals, such as figure 1 As shown in a, 1b, 1c, and 1d, it includes fixed knife rest assembly 1, movable knife rest assembly 2, lead screw 3, guide rail 4, motor 5, component support frame 6, limit block 7, travel switch 8, lead screw 3 , guide rails 4 are installed on the upper surface of the component support frame 6, the lead screw 3 is installed on the platform of the component support frame 6, the fixed knife rest assembly 1 is fixed on the head end of the component support frame 6 platform, and the head end of the lead screw 3 passes through the fixed knife frame The bottom of component 1 is hollow and not connected to fixed tool holder component 1. The other end of lead screw 3 is connected to the output end of motor 5. Motor 5 is installed at the end of the platform of component support frame 6. At the same time, guide rail 4 is installed in parallel with lead screw 3 , is also installed on the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com