Fine waste battery sagger grinding device

A technology for fine grinding and used batteries, applied in grinding/polishing safety devices, grinding machines, grinding racks, etc., can solve the problems of inability to grind waste batteries first, and inability to wipe off rare metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below.

[0028] The reference signs in the accompanying drawings of the specification include:

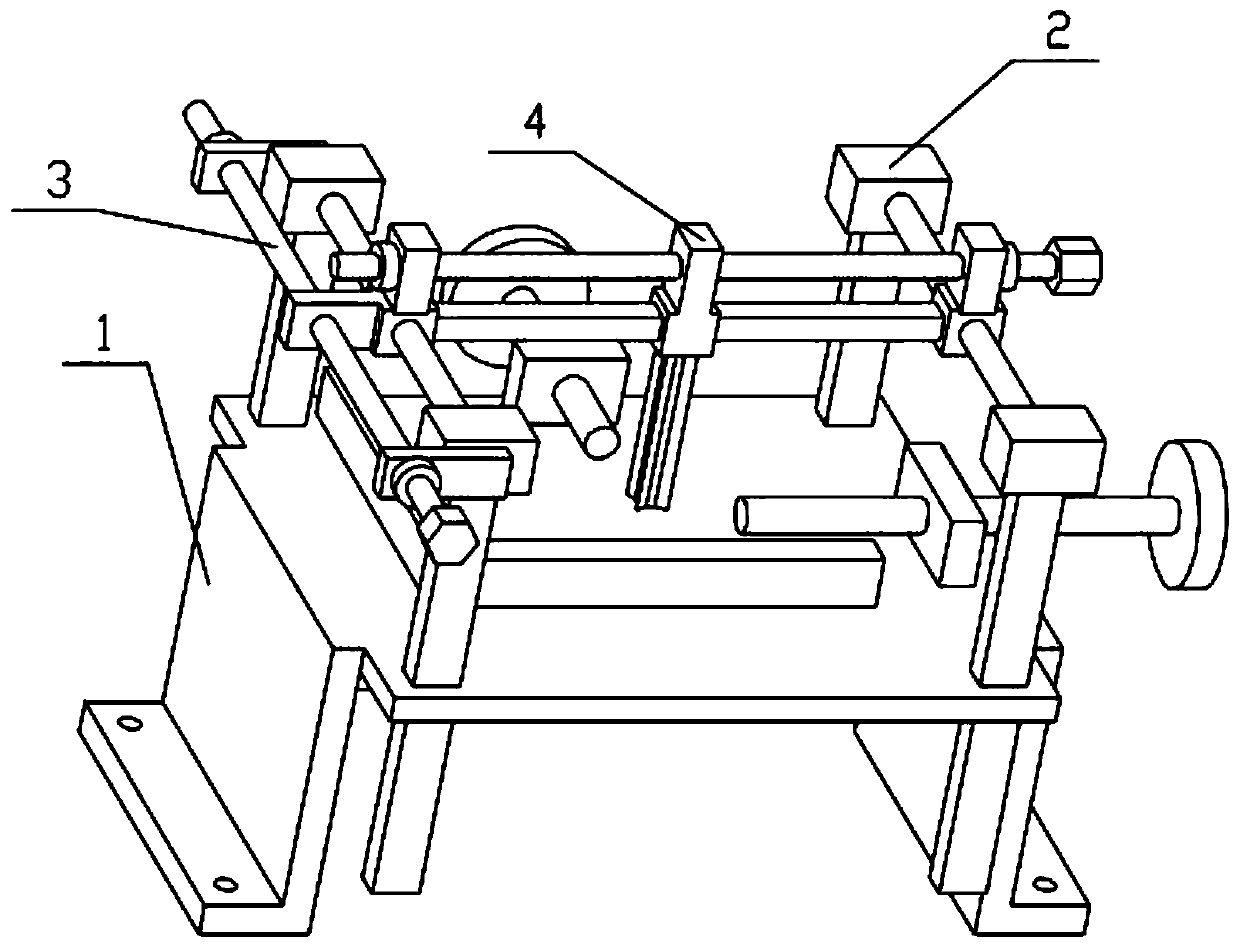

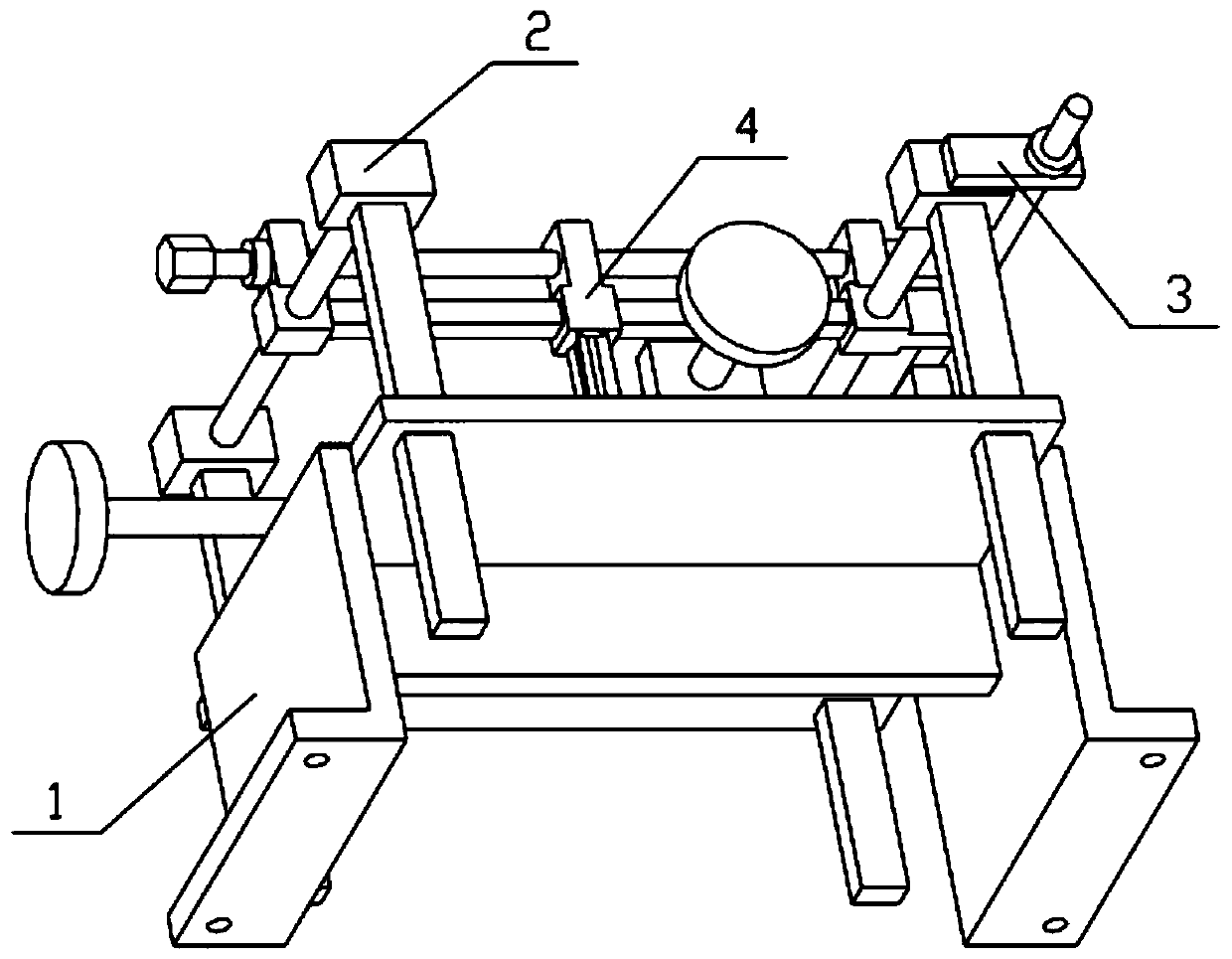

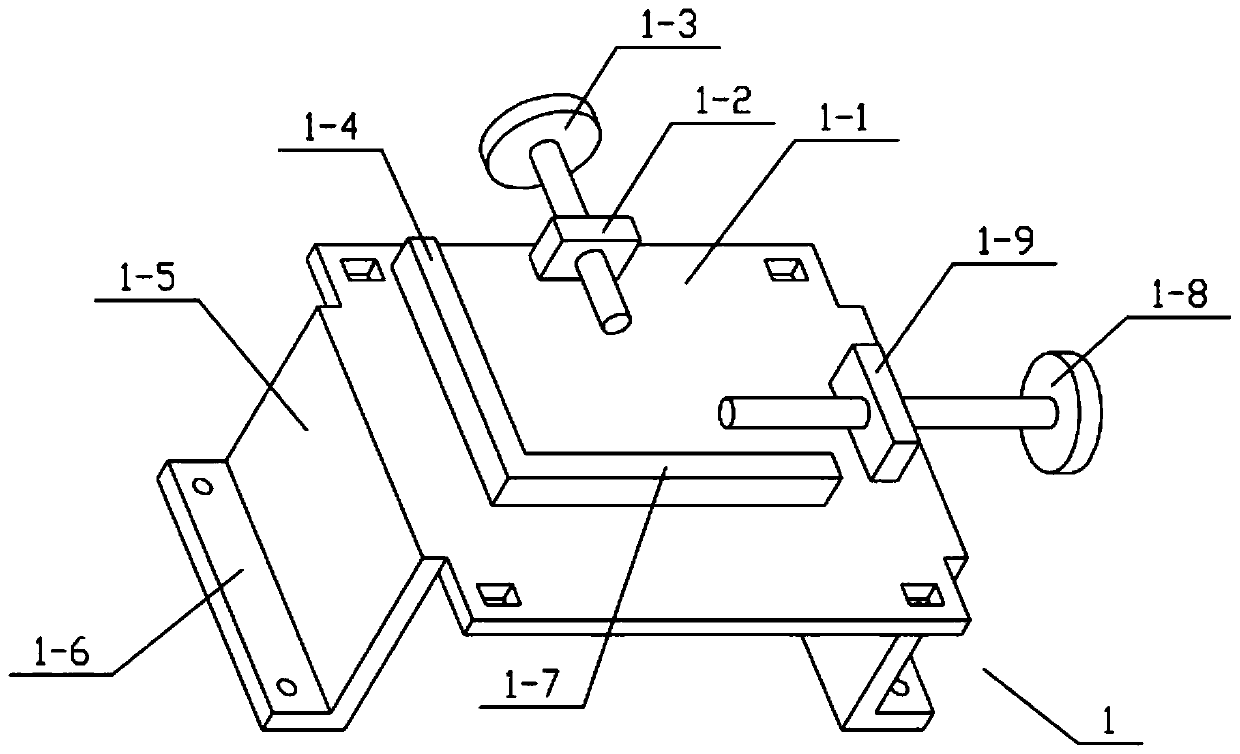

[0029] Sagger placement table 1; working flat plate 1-1; rear convex seat 1-2; rear screw 1-3; vertical retaining edge 1-4; support plate 1-5; screw insert plate 1-6; 7; right screw 1-8; right convex seat 1-9; lifting frame 2; vertical slide bar 2-1; circular track rod 2-2; slider 2-3; -5; lead screw I2-6; beam rod 2-7; front and rear adjustment mechanism 3; side plate 3-1; threaded orifice plate 3-2; lead screw II3-3; limit ring II3-4; Threaded hole block 4-1; sliding sleeve 4-2; rectangular column 4-3; triangular convex edge 4-4.

[0030] Such as Figure 1-6 A waste battery sagger fine grinding device shown includes a sagger placement platform 1, a lifting frame 2 and a grinding tool 4. The sagger placement platform 1 includes a working plate 1-1, a vertical retaining edge 1-4, a support Plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com