Intelligent assembly detection workbench trolley and use method thereof

An assembly inspection and workbench technology, applied in workshop equipment, manufacturing tools, tool storage devices, etc., can solve the problems of unqualified workpiece processes, unqualified torque, time-consuming and laborious, and achieve high standardization, reasonable layout, and labor reduction. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

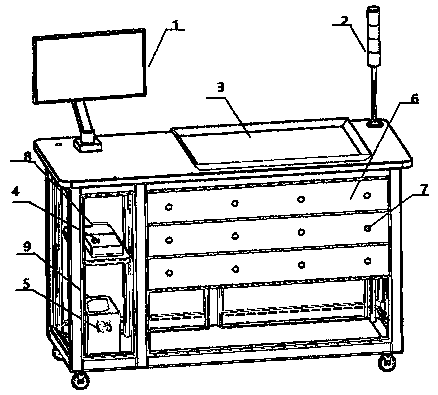

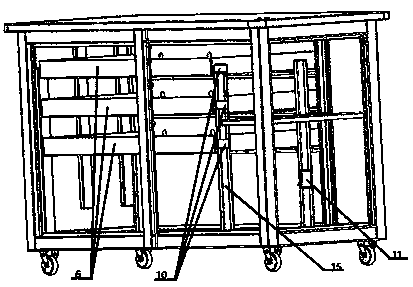

[0032] like Figure 1 to Figure 4 The shown intelligent assembly and inspection work trolley includes a program control module, an induction module, a data transmission module, an indication module, a power supply module and a work trolley body.

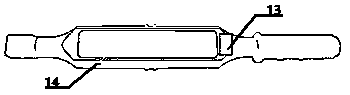

[0033] The program control module includes an industrial computer 4 and a programmable relay controller 8; the induction module includes an RFID card reader 11, an RFID antenna 12, an RFID electronic tag 13 and a proximity switch sensor 10; the data transmission module is based on TCP / IP protocol wireless communication equipment; the indication module includes a display 1, a bamboo lamp 2 and an LED indicator 7; the power supply module includes a UPS5 and a switching power supply 9.

[0034] Display 1, mouse and keyboard, bamboo lamp 2, common tool tray 3 are placed on the body table, and electrical equipment such as UPS5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com