Taking and placing device and taking and placing method

A pick-and-place device and mounting hole technology, applied in the manufacturing field, can solve problems such as defects, OLED display screen collision stress, concentration, etc., and achieve the effects of protecting products, increasing yield, and reducing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

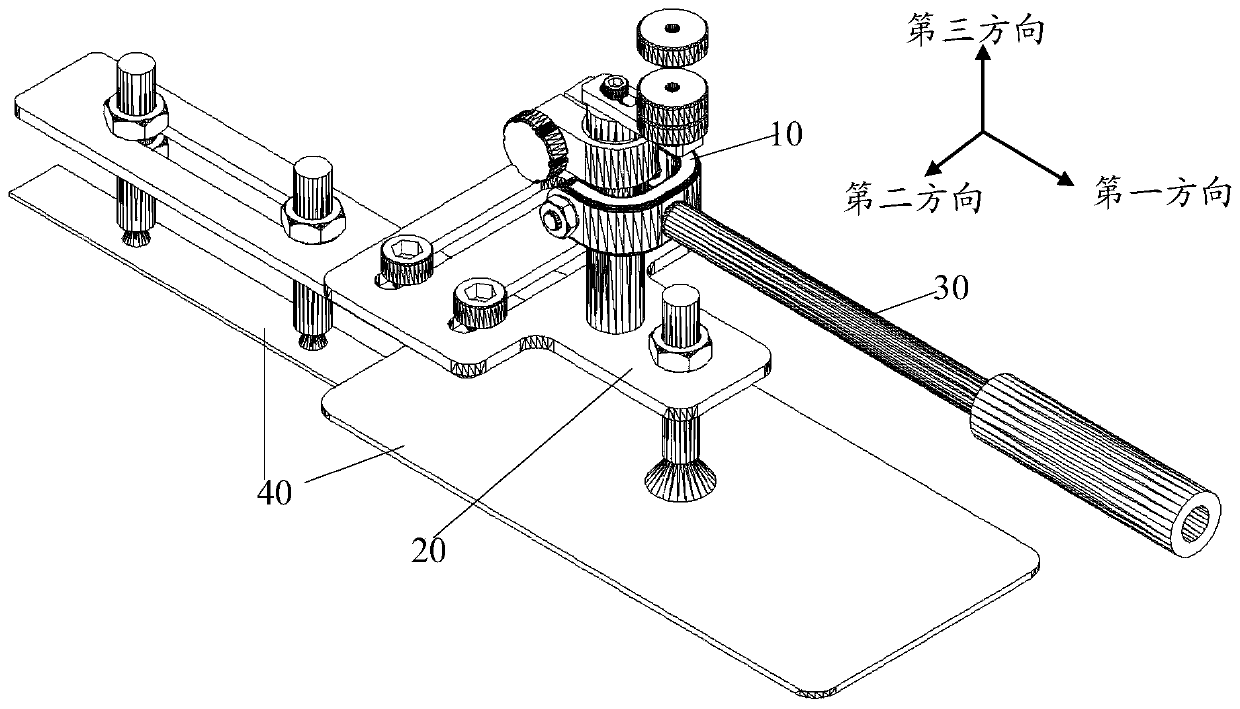

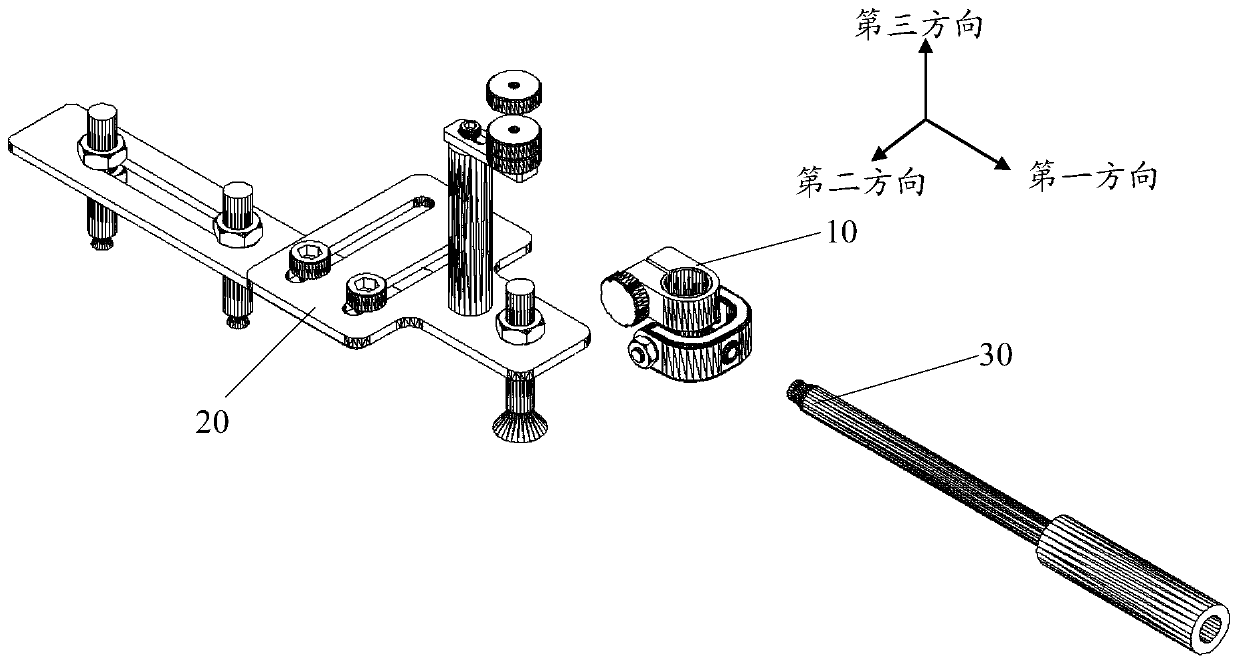

[0057] refer to figure 1 , shows a schematic structural view of a pick-and-place device provided by an embodiment of the present invention. The device includes a three-axis balance joint 10, an adsorption assembly 20 and a control handle 30, referring to figure 2 The exploded structure diagram of the pick-and-place device shown;

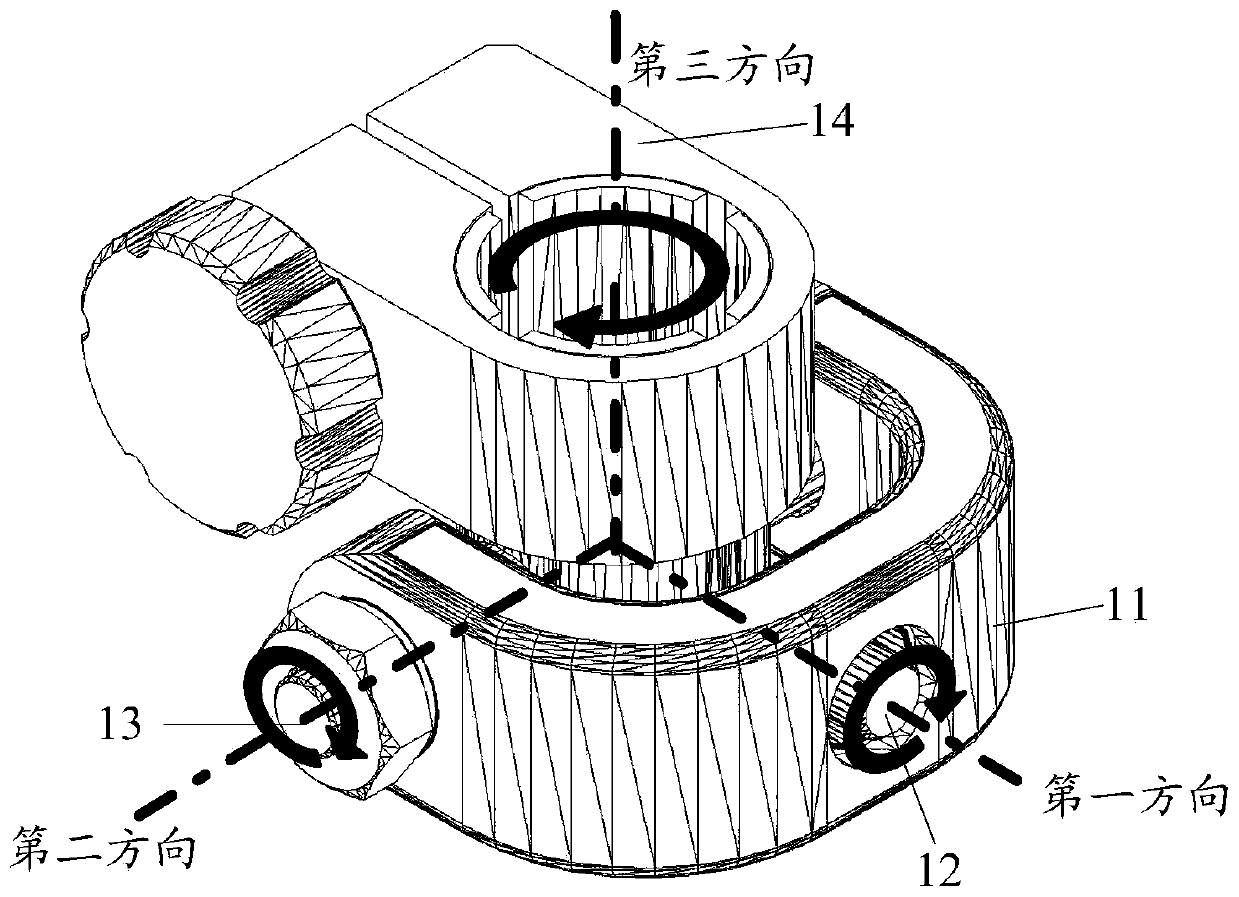

[0058] The three-axis balance joint 10 has rotational degrees of freedom in three directions in a three-dimensional coordinate system;

[0059] The adsorption assembly 20 and the control handle 30 are respectively fixedly connected to the three-axis balance joint 10;

[0060] The suction assembly 20 is used for vacuum suctioning the target object 40 .

[0061] In this embodiment, the adsorption assembly 20 and the control handle 30 are respectively fixedly connected to the three-axis balance joint 10. Since the three-axis balance joint 10 has rotational degrees of freedom in three directions in the three-dimensional coordinate system, the target ...

Embodiment 2

[0109] refer to Figure 5 , shows a flowchart of steps of a pick-and-place method provided by an embodiment of the present invention. Applied to the pick-and-place device as described in Embodiment 1, the method includes:

[0110] Step 501 , turn on the vacuum of the adsorption assembly 20 through the control handle 30 .

[0111] In this embodiment, the control handle 30 includes a handle and a vacuum system, and the vacuum system includes a vacuum generator, a vacuum control valve, and a positive pressure air interface. The air path between the vacuum generator and the adsorption assembly 20 is connected through the vacuum control valve, so as to open the vacuum of the adsorption assembly 20 .

[0112] Step 502, hovering the adsorption assembly 20 directly above the target object, and controlling the pick-and-place device to fall, so that the adsorption assembly 20 vacuum-adsorbs the target object.

[0113] In this embodiment, the adsorption assembly 20 includes a fourth c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com