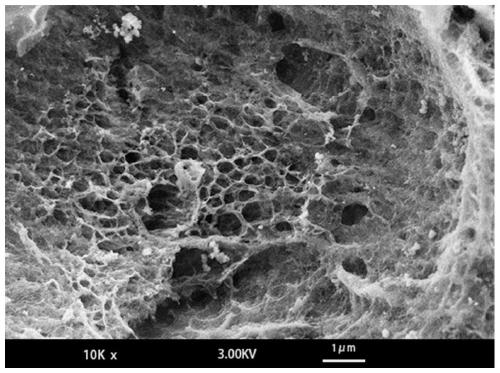

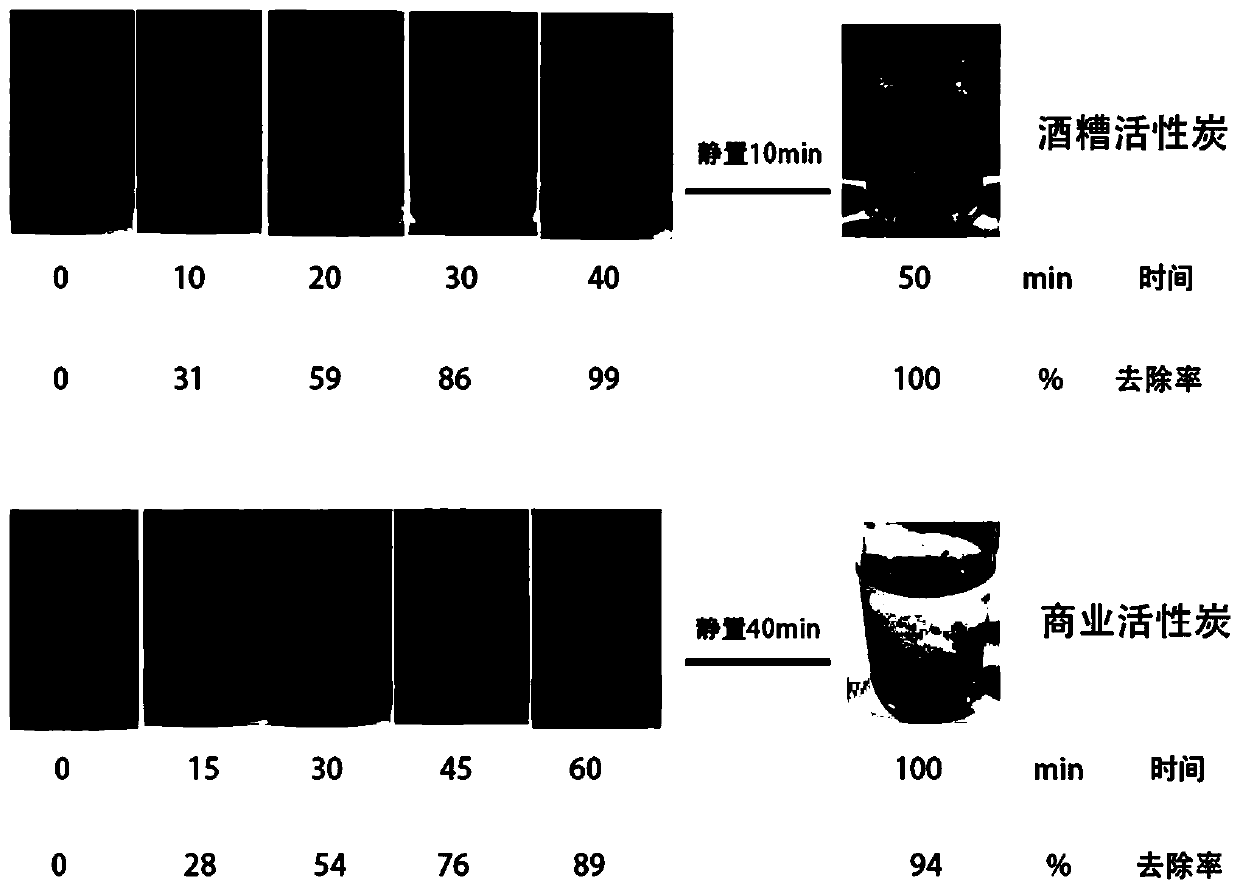

Preparation method of distiller's grains activated carbon with high specific surface area

A technology of activated carbon preparation and high specific surface area, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of unsatisfactory performance of activated carbon and cumbersome preparation process, and achieve low cost, convenient operation and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Dry the distiller's grains first, grind and pulverize them, filter them through a 100-mesh sieve, place them in a carbonization furnace, and pass nitrogen gas for 10 minutes after sealing them well. Adjustment parameters: initial temperature 20°C, heating rate 5°C / min, heating temperature 350°C, heat preservation 1h. After cooling, the carbonized material is taken out.

[0023] (2) Prepare 25wt% KOH solution and carbonized material at a solid-to-liquid ratio of 4:1, stir on a stirrer for 10 minutes, and dry in an oven at 60°C for 12 hours.

[0024] (3) Put the carbonized material in step 2 in the heating furnace, first pass nitrogen gas for 10 minutes, then start heating, control the heating rate at 10°C / min, set the activation temperature at 650°C, keep it for 2 hours, and take it out after cooling.

[0025] (4) Configure 20wt% dilute hydrochloric acid and continuously add it dropwise into the activated material obtained in step 3), until the reaction is mild and ...

Embodiment 2

[0028] (1) Dry the distiller's grains first, grind and pulverize them, filter them through a 100-mesh sieve, place them in a carbonization furnace, and pass nitrogen gas for 10 minutes after sealing them well. Adjustment parameters: initial temperature 20°C, heating rate 5°C / min, heating temperature 450°C, heat preservation 1.5h. After cooling, the carbonized material is taken out.

[0029] (2) Prepare 25wt% KOH solution and carbonized material at a solid-to-liquid ratio of 4:1, stir on a stirrer for 10 minutes, and dry in an oven at 60°C for 12 hours.

[0030] (3) Put the carbonized material in step 2 in a tube furnace, first pass nitrogen gas for 10 minutes, then start heating, control the heating rate at 10°C / min, set the activation temperature at 750°C, keep it for 2 hours, and take it out after cooling.

[0031] (4) Configure 20wt% dilute hydrochloric acid and continuously drop it into the activated material obtained in step 3), and stop the dropping after the reaction i...

Embodiment 3

[0035] (1) Dry the distiller's grains first, grind and pulverize them, filter them through a 100-mesh sieve, and place them in a carbonization furnace. Introduce nitrogen gas for 10 minutes, adjust parameters: initial temperature 20°C, heating rate 5°C / min, heating temperature 500°C, hold for 2 hours. After cooling, the carbonized material is taken out.

[0036] (2) Prepare 25wt% KOH solution and carbonized material at a solid-to-liquid ratio of 4:1, stir on a stirrer for 10 minutes, and dry in an oven at 60°C for 12 hours.

[0037] (3) Put the carbonized material in step 2 in the heating furnace, first pass nitrogen gas for 10 minutes, then start heating, control the heating rate at 10°C / min, set the activation temperature at 850°C, keep it for 2 hours, and take it out after cooling.

[0038] (4) Configure 20wt% dilute hydrochloric acid and continuously add it dropwise into the activated material obtained in step 3), and stop the dropwise addition after the reaction is mild ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com