Decoloration agent for removing color of defoamer on ultrawhite high-turbine flat glass and using method

A technology of flat glass and decolorizer, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as the influence of glass color, and achieve the effect of reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

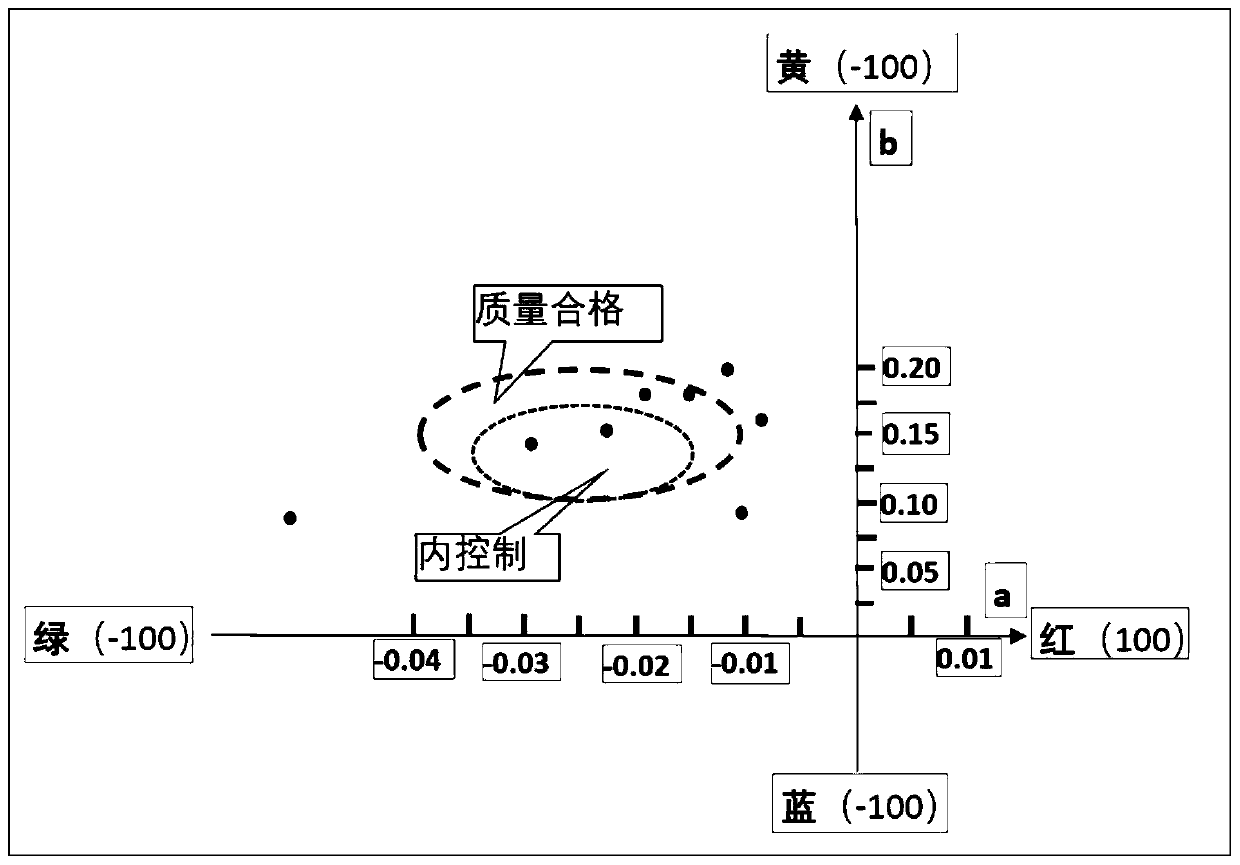

Image

Examples

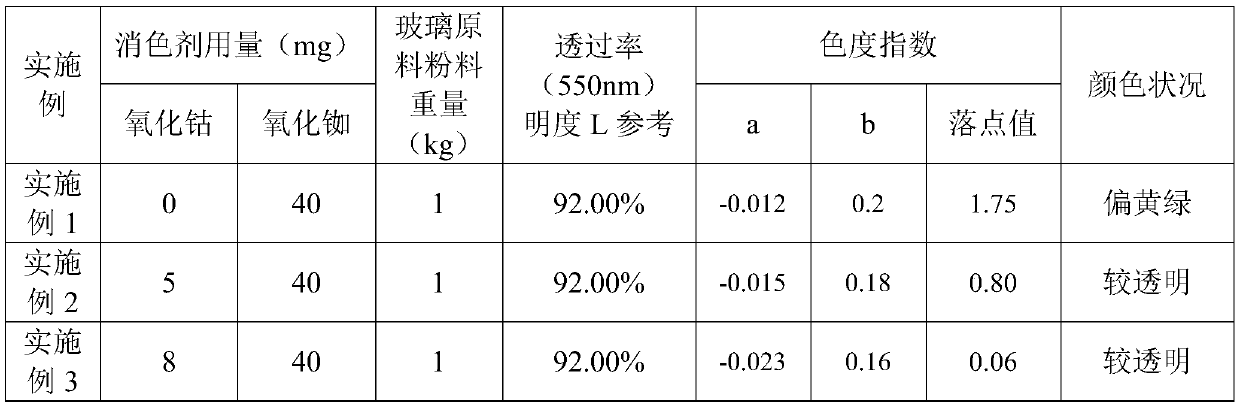

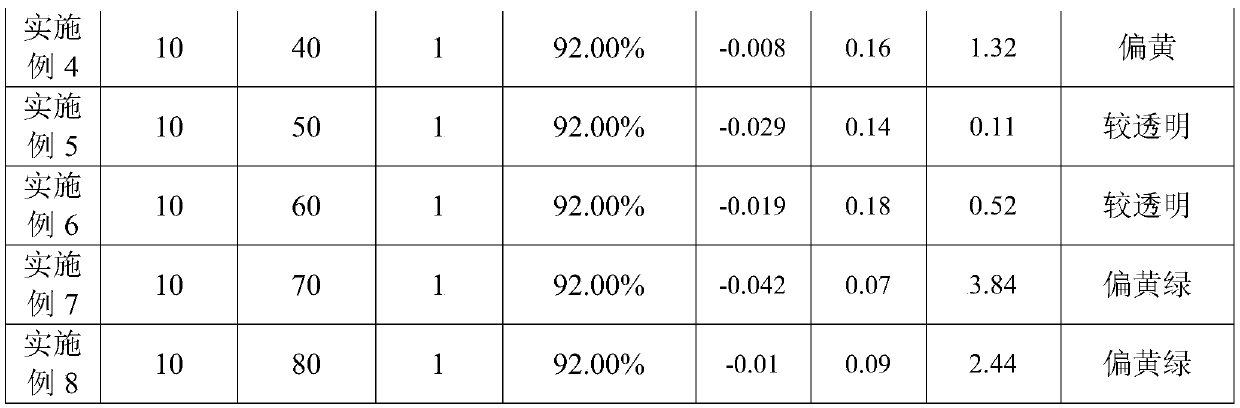

Embodiment 1-8

[0024] The chemical composition of the ultra-white and high-transparency flat glass used in Examples 1-8 is: SiO 2 60.0wt%, Al 2 o 3 1.5wt%, MgO is 4.0wt%, CaO is 8.0wt%, Na 2 O is 14.0wt%, Fe 2 o 3 90ppm, TiO 2 50ppm.

[0025] Examples 1-8 all select high-purity silica sand, alumina powder, limestone, dolomite, soda ash, and thenardite raw materials according to the above-mentioned chemical composition of the glass. The specifications of each raw material are as follows: high-purity silica sand (SiO 2 ≥98.5wt%, Al 2 o 3 ≤1.1wt%, Fe 2 o 3 ≤100ppm; TiO 2 content≤60ppm), alumina powder (Al 2 o 3 ≥99.0wt%, Fe 2 o 3 ≤200ppm;), limestone (CaO is 55.00±0.5%wt%, Fe 2 o 3 ≤80ppm; TiO 2 content≤80ppm), dolomite (MgO is 21.00±1.0wt%, CaO is 32.00±1.0wt%, Fe 2 o 3 ≤80ppm; TiO 2 content≤80ppm), soda ash (Na 2 CO 3 ≥99.5wt%, Fe 2 o 3 ≤50ppm; TiO 2 content ≤50ppm), thenardite (Na 2 SO 3 ≥99.0wt%, Fe 2 o 3 ≤100ppm; TiO 2 content≤50ppm).

[0026] In Examples 1-...

Embodiment 2

[0035] Based on the chemical composition and test results of Example 1, a trial production was carried out in a company's 550 tons / day ultra-clear and high-permeable float flat glass float production line, and the raw materials used mainly include high-purity silica sand (SiO ≥ 98.5wt%) , Al 2 o 3 ≤1.1wt%, Fe 2 o 3 ≤100ppm; TiO 2 content≤60ppm), alumina powder (Al 2 o 3 ≥99.0wt%, Fe 2 o 3 ≤200ppm;), limestone (CaO is 55.00±0.5%wt%, Fe 2 o 3 ≤80ppm; TiO 2 content≤80ppm), dolomite (MgO is 21.00±1.0wt%, CaO is 32.00±1.0wt%, Fe 2 o 3 ≤80ppm; TiO 2 content≤80ppm), soda ash (Na 2 CO 3 ≥99.5wt%, Fe 2 o 3 ≤50ppm; TiO 2 content ≤50ppm), thenardite (Na 2 SO 3 ≥99.0wt%, Fe 2 o 3 ≤100ppm; TiO 2 Content ≤ 50ppm); Considering the production cost, the titanium ion raw material that can produce glass coloring is used;

[0036] The specific dosage of each raw material is as follows: 325 tons of high-purity silica sand; 2.5 tons of alumina powder; 90 tons of dolomite; 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com