Polar polymer negative poisson ratio foam material and preparation method thereof

A polar polymer and negative Poisson's ratio technology, applied in the field of polar polymer negative Poisson's ratio foam materials and their preparation, can solve the problems of unfavorable large-scale production, cumbersome preparation process, and low preparation efficiency, and achieve production Low cost, simple process, good anti-notch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

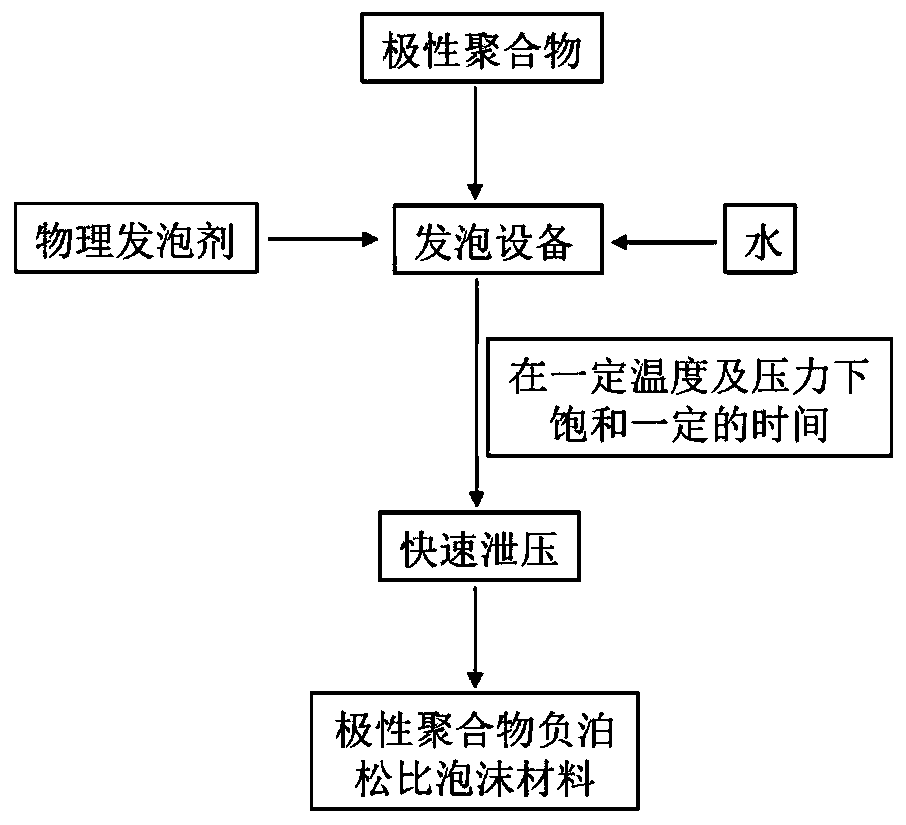

Method used

Image

Examples

preparation example Construction

[0033] The processing condition of preparation method of the present invention:

[0034] The temperature is selected at 80-180°C, because if the temperature is lower than 80°C, the foaming effect of the polymer matrix is not good; if the temperature is higher than 180°C, the melt strength of the polymer matrix is low, and the cells are prone to collapse and rupture. Not conducive to negative Poisson's ratio transitions. The preferred temperature is 90-160°C, more preferably 100-150°C.

[0035] The pressure is selected at 3-25MPa, because the pressure is lower than 3MPa, the cells of the polar polymer foam are larger and the mechanical strength is lower, and when the pressure is higher than 25MPa, the melt strength of the polar polymer resin matrix cannot withstand it. If the pressure is too high, the prepared foam will break holes, which is not conducive to the transformation of negative Poisson's ratio. The saturation pressure is preferably 5 to 16 MPa.

[0036] It tak...

Embodiment 1

[0041] Firstly, chlorinated polypropylene (Shandong Yaxing, CPE, 135A) is made into 60×60×4mm by heating and molding 3 The parts to be foamed are heated and molded at a temperature of 160°C; the parts to be foamed are placed in CO at 145°C and 25MPa 2 and water foaming equipment for 0.5h, and then release the pressure to normal pressure at a pressure release rate of 12MPa / s. During the process of pressure release and foaming, the product to be foamed will be discharged out of the foaming device with the pressure release gas to complete the foaming process. Foam to obtain chlorinated polypropylene foam material with negative Poisson's ratio.

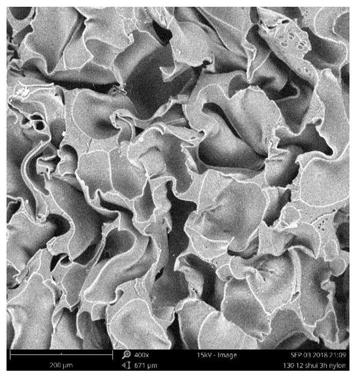

[0042] After testing, the foam material has a cell structure with "concave corners", and the SEM photos are as follows figure 2 Shown; the Poisson's ratio of the material is tested according to the GB / T1040.1-2006 standard, and the Poisson's ratio is -1.1.

Embodiment 2

[0044] First, nylon copolymer resin (French Atofina, PEBAX 1940) is made into 60×60×5mm by injection molding machine 3 The parts to be foamed, the temperature of the injection molding machine is 160°C; the parts to be foamed are placed in 130°C, 12MPa CO 2 and water foaming equipment for 3 hours, and then quickly release the pressure to normal pressure at a pressure release rate of 2MPa / s. During the process of pressure release and foaming, the product to be foamed remains in the foaming equipment to complete foaming, and then Open the foaming device and take it out to obtain a nylon copolymer resin negative Poisson's ratio foam material.

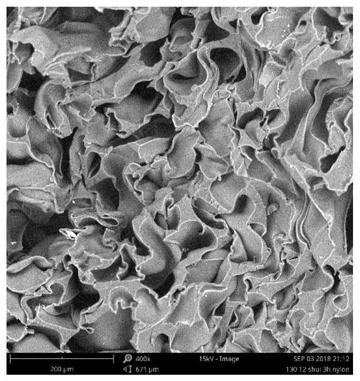

[0045] After testing, the foam material has a cell structure with "concave corners", and the SEM photos are as follows figure 2 As shown; the Poisson's ratio of the material is tested according to the GB / T1040.1-2006 standard, and the Poisson's ratio is -1.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com