A coating material for light alloy pulping and its preparation method

A coating material, light alloy technology, applied in the direction of coating, etc., to achieve the effect of high defoaming, good film forming and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

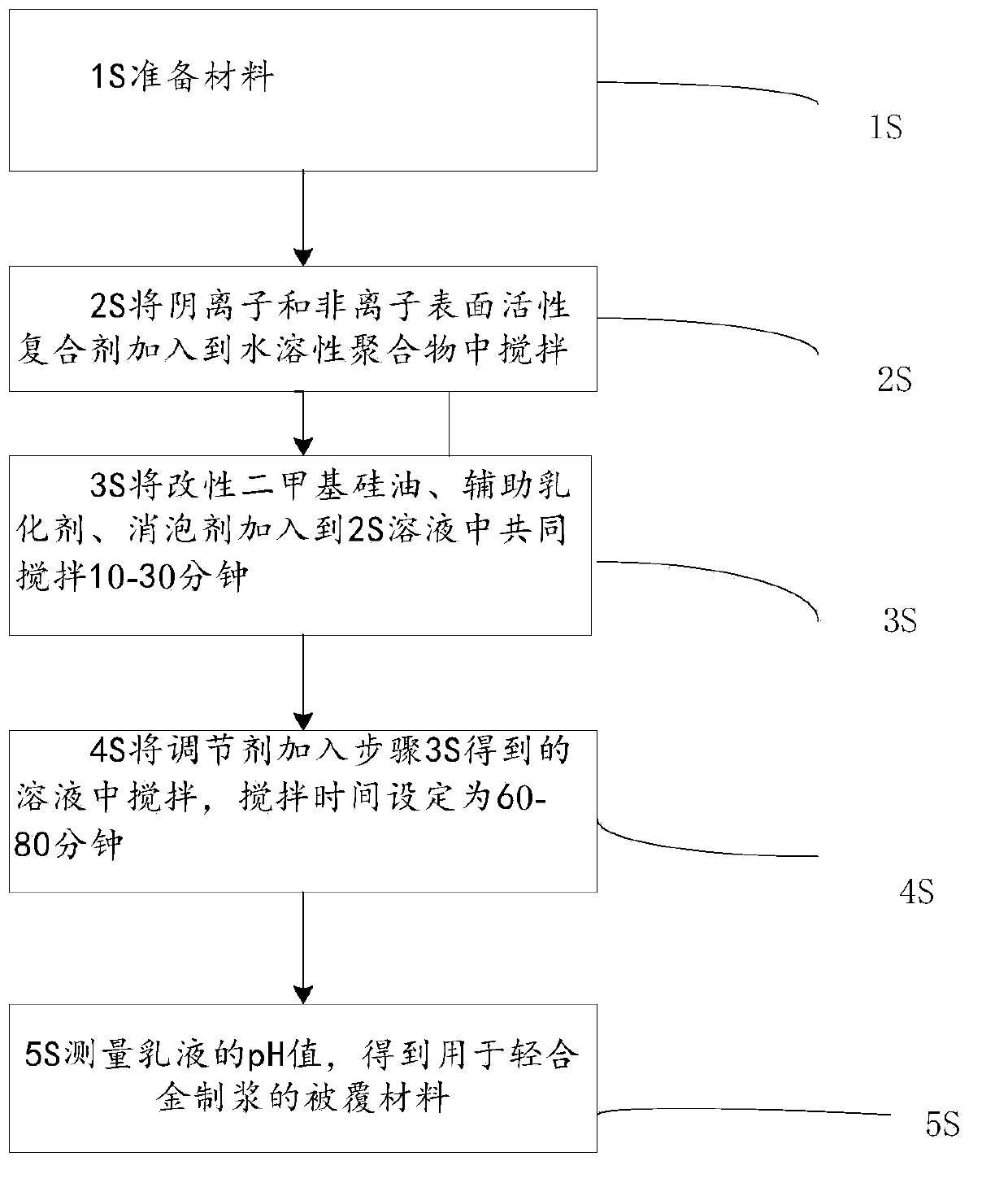

[0038] Such as figure 1 As shown, the preparation method of the coating material for light alloy pulping comprises the following steps:

[0039] 1S prepares modified simethicone, anionic and nonionic surfactant compounding agents, co-emulsifiers, water-soluble polymers, regulators and defoamers.

[0040] 2S Add the anionic and nonionic surfactant compounding agent into the water-soluble polymer and stir for 10-20 minutes.

[0041] 3S Add modified simethicone, auxiliary emulsifier, and defoamer to the solution in step 2S and stir together under constant temperature water bath conditions. The stirring time is set at 10-30 minutes, and the water bath temperature is 45-60 degrees Celsius.

[0042] 4S: Add the regulator to the solution obtained in step 3S, and stir at 20-25 degrees Celsius until the solution becomes a uniform and transparent emulsion, stop stirring, and set the stirring time to 60-80 minutes.

[0043] 5S measures the pH value of the emulsion obtained in step 4S, ...

Embodiment 1

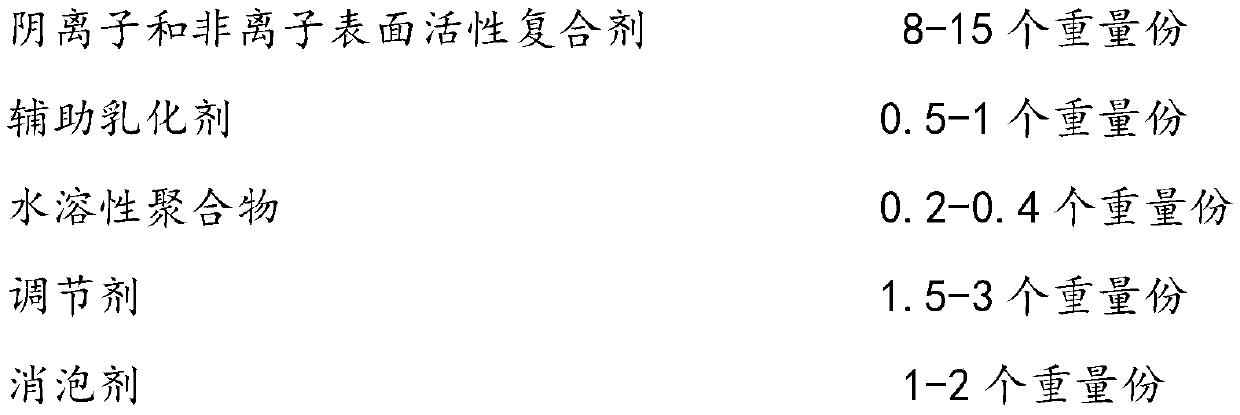

[0046] A coating material for light alloy pulping contains the following components, and the content of each component indicates

[0047] as follows:

[0048]

[0049] The coating material used for light alloy pulping in Example 1 has excellent high-temperature wettability, and the coated stirring rod can quickly form a layer of high-temperature resistant, erosion-resistant, micron-scale thick at a temperature as high as 450 degrees Celsius. Uniform film.

Embodiment 2

[0051] A coating material for light alloy pulping contains the following components, and the content of each component is expressed as follows:

[0052]

[0053] The coating material used for light alloy pulping in Example 2 has excellent corrosion resistance and increases the number of uses of the stirring rod. The traditional stirring rod uses hot-work steel H13 material to produce 3000 molds, that is, the surface corrosion is scrapped, and the coating of Embodiment 2 is used. After the material is coated with the stirring rod, the service life is as high as 11000 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com