Frosted pre-coating and preparation method thereof

A pre-coating and frosting technology, applied in the direction of coating, film/sheet release coating, film/sheet adhesive, etc. There are no problems such as anti-friction effect, and the effect of good artistic effect and recognition, good decoration and protection effect, and uniform matte texture can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

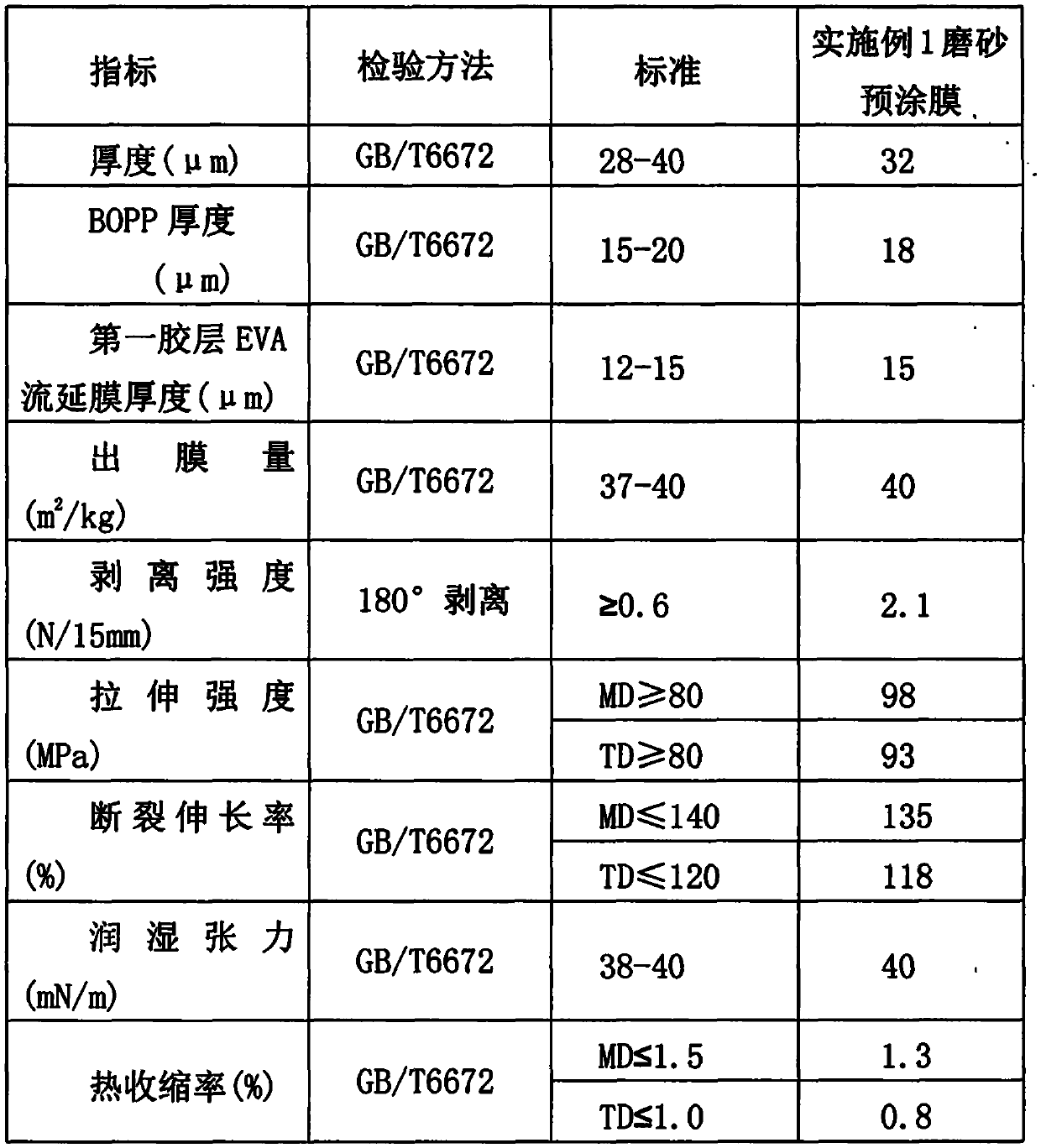

Embodiment 1

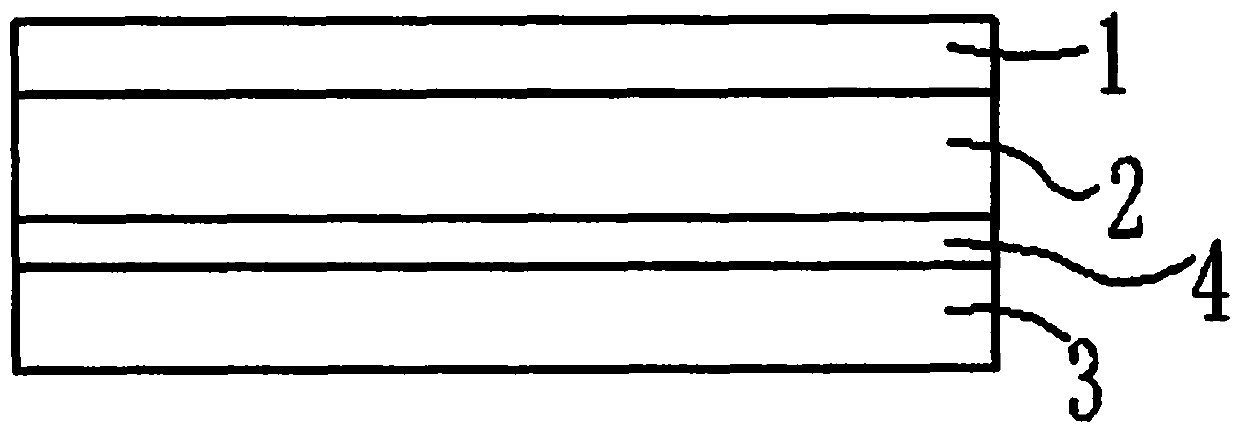

[0032] The frosted pre-coating film of the present embodiment comprises a frosted coating layer 1 formed on the substrate layer 2, the bottom of the substrate layer 2 is coated with a hot melt adhesive layer 3, and the pre-coated film is bonded with the printed matter through the hot melt adhesive layer 3 complex. The design of the matte paint layer makes the surface of the printed matter after the composite precoating film have better anti-friction and anti-fouling properties, so that the printed matter has a better use effect.

[0033] The frosted paint layer 1 is molded with a glare pattern, and the glare pattern includes a glare strip and a reflective strip with an artistic text effect, and the glare strip and the reflective strip can be correspondingly typeset according to the actual artistic effect requirements, so that Produce pre-coated films with different artistic effects. For example, the glare strips and reflective strips can be typeset into congratulations, bless...

Embodiment 2

[0044] The frosted precoat film of the present embodiment is basically the same in structure as in Example 1, the difference is that the thickness of the frosted paint layer is 4 μm; the material of the substrate layer 2 is a corona-treated BOPP film, and the substrate The thickness of the layer 2 is 15 μm; the material of the hot melt adhesive layer 3 is EVA, and the thickness of the hot melt adhesive layer 3 is 13 μm.

[0045] The preparation method of the frosted precoat film of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0047] The frosted pre-coating film of this embodiment is basically the same in structure as in Example 1, the difference is that the frosted pre-coating film also includes an undercoat layer formed between the substrate layer 2 and the hot-melt adhesive layer 3, the The solvent used for the primer layer is polyethyleneimine aqueous solution.

[0048]The thickness of the frosted paint layer is 3 μm; the material of the substrate layer 2 is a corona-treated BOPP film, and the thickness of the substrate layer 2 is 20 μm; the material of the hot melt adhesive layer 3 is EVA, the The thickness of the hot melt adhesive layer 3 is 15 μm.

[0049] The preparation method of the frosted precoat film of the present embodiment may further comprise the steps:

[0050] Substrate unwinding: select BOPP film as the substrate, and release the BOPP film with unwinding equipment;

[0051] Frosted pattern treatment: install the BOPP film with a thickness of 18μm and a width of 1080mm on the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com