Method for preparing composite phase change materials on basis of polished ceramic tile waste materials

A technology of composite phase change materials and ceramic polishing tiles, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of surrounding environmental pollution, land, resource waste, etc., to reduce production costs, improve rigidity, and increase resources. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0038] A method for preparing composite phase change materials based on ceramic polished brick waste

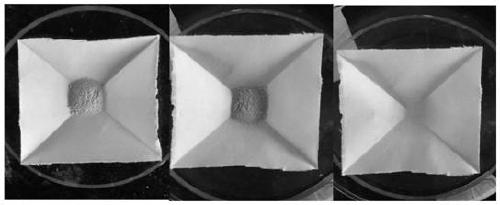

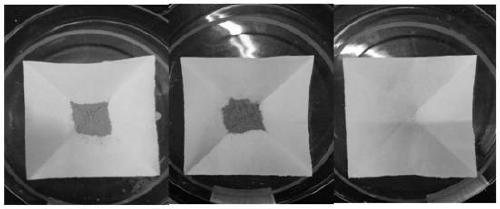

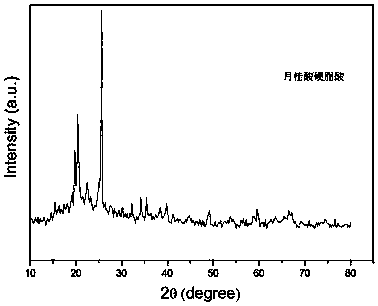

[0039] (1) Take a clean and dry beaker, use a balance to weigh lauric acid and stearic acid with a mass ratio of 4:1 in the beaker, put the beaker in a water bath at 80°C and heat until the solid is completely melted, Stir evenly with a glass rod, take out the beaker, and let the mixture cool and solidify in the air, that is, a lauric acid / stearic acid eutectic phase change material with a phase transition temperature of about 30° C. is produced.

[0040] (2) Take a certain amount of waste porcelain powder / kaolin (mass ratio is 1:1), and the starch that accounts fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com