High hardness waterborne polyurethane fabric coating adhesive and preparation method thereof

A water-based polyurethane and textile coating technology, applied in textiles and papermaking, etc., to achieve excellent yarn fastness, low cost, high-strength seam anti-slip strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

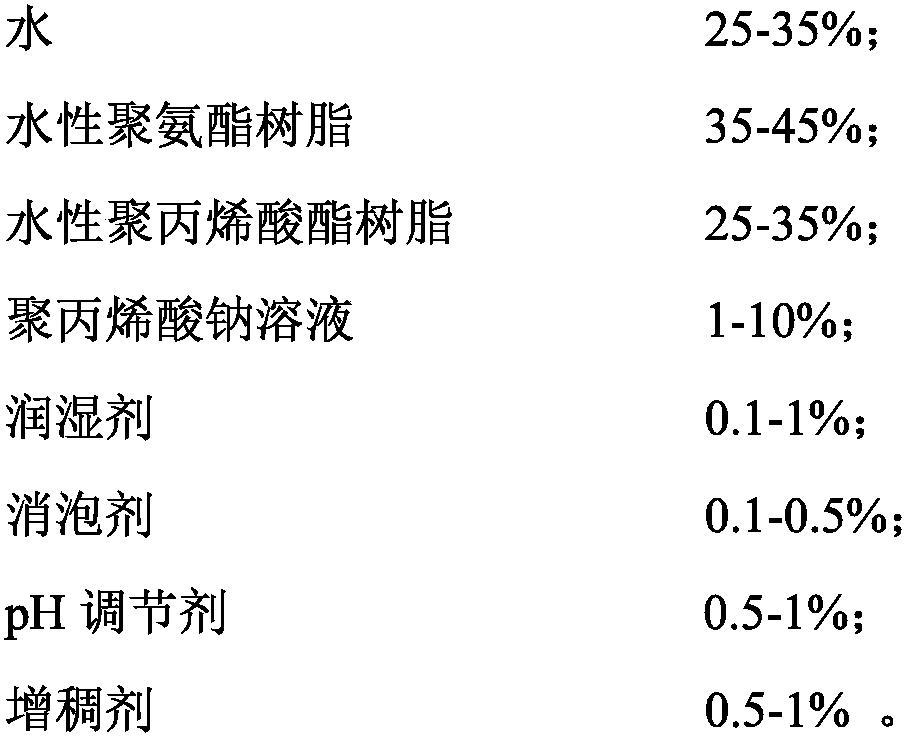

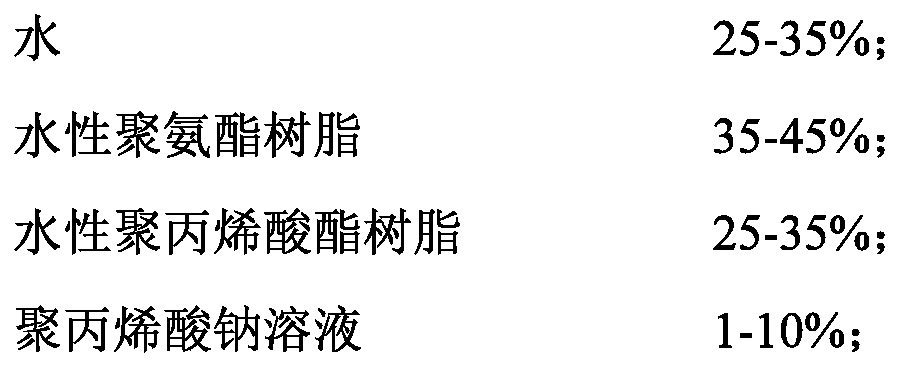

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a kind of preparation method of textile coating glue, comprises the following steps:

[0036] S1. Add 26% water and 32.9% water-based polyacrylate resin to the dispersion kettle to dissolve the water-based polyacrylate resin in water to obtain a water-based polyacrylate resin solution, and then slowly and uniformly add 0.5% water-based polyacrylate resin to the dispersion kettle % pH adjuster to adjust the pH value of the aqueous polyacrylate resin solution so that the pH value of the mixed solution is 6 to 8, which is recorded as the first mixed solution;

[0037] S2. Stir the first mixed solution. At the same time, in the state of stirring, add 37% water-based polyurethane resin into the dispersion tank, and stir evenly, so that the water-based polyurethane is uniformly mixed in the water-based polyacrylate resin solution to obtain the second mixture;

[0038] S3. Add 1% polyoxyethylene ether and 0.1% silicone defoamer to the second mixed solut...

Embodiment 2

[0045] The invention provides a kind of preparation method of textile coating glue, comprises the following steps:

[0046] S1. Add 30% water and 24% water-based polyacrylate resin to the dispersion tank to dissolve the water-based polyacrylate resin in water to obtain a water-based polyacrylate resin solution, and then slowly and uniformly add 0.5% water-based polyacrylate resin to the dispersion tank % pH adjuster to adjust the pH value of the aqueous polyacrylate resin solution so that the pH value of the mixed solution is 6 to 8, which is recorded as the first mixed solution;

[0047] S2. Stir the first mixed solution. At the same time, under the state of stirring, add 43% water-based polyurethane resin into the dispersion tank, and stir evenly, so that the water-based polyurethane is uniformly mixed in the water-based polyacrylate resin solution to obtain the second mixture;

[0048] S3. Add 0.2% of anionic surfactant and 0.1% of silicone defoamer to the second mixed sol...

Embodiment 3

[0055]The invention provides a kind of preparation method of textile coating glue, comprises the following steps:

[0056] S1. Add 31% water and 28% water-based polyacrylate resin to the dispersion tank to dissolve the water-based polyacrylate resin in water to obtain a water-based polyacrylate resin solution, and then slowly and uniformly add 0.25% % pH adjuster to adjust the pH value of the aqueous polyacrylate resin solution so that the pH value of the mixed solution is 6 to 8, which is recorded as the first mixed solution;

[0057] S2. Stir the first mixed solution. At the same time, under the state of stirring, add 38% water-based polyurethane resin to the dispersion tank, and stir evenly, so that the water-based polyurethane is uniformly mixed in the water-based polyacrylate resin solution to obtain the second mixture;

[0058] S3. Add 0.6% polyoxyethylene ether and 0.5% modified polysiloxane emulsion to the second mixed solution, and stir evenly to obtain the third mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com