Dredging and sludge disposal method for an open pit

A technology for open-pit mining and silt, which is applied in filling, protective devices, mining equipment, etc., can solve the problems of complex operation and maintenance, large equipment investment, and low processing efficiency, so as to improve economic benefits, reduce dredging costs, and avoid Effect of dredging equipment and pipeline costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further describe the present invention, a method for dredging and sludge disposal of an open-pit pit according to the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

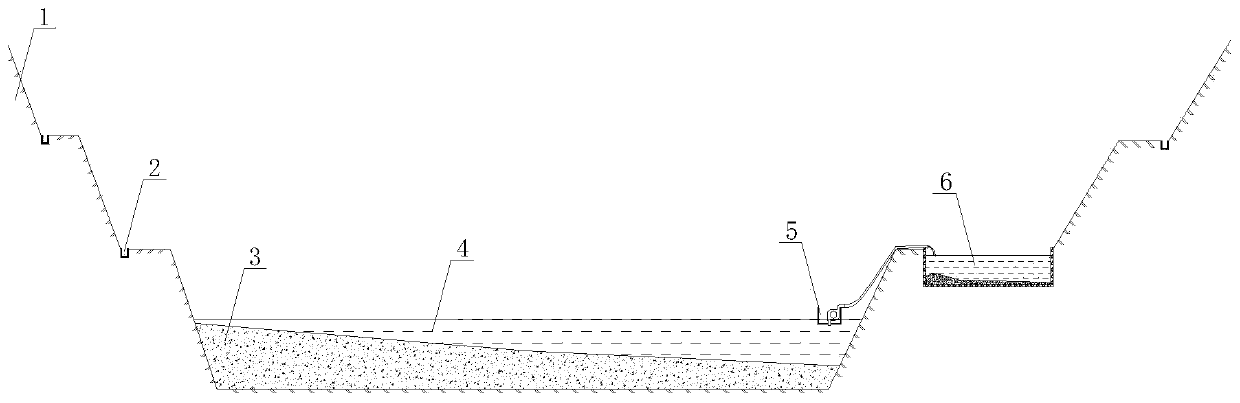

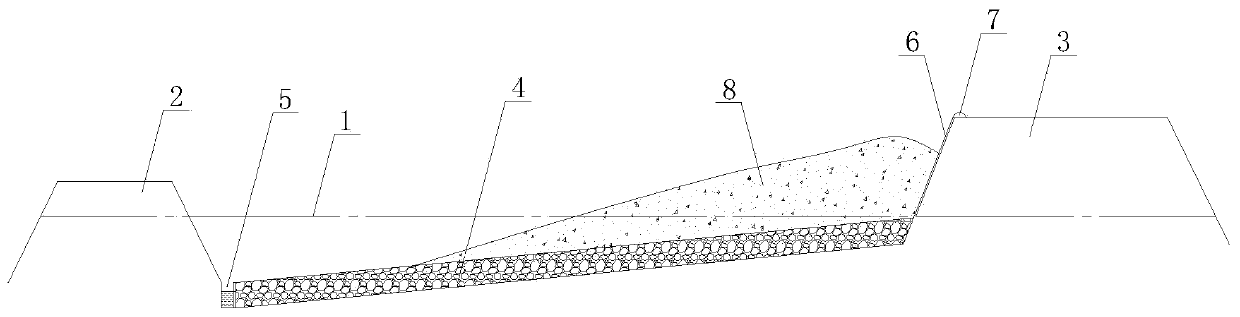

[0021] Such as figure 1 As shown, a method for dredging and sludge disposal in an open pit, the construction steps are as follows:

[0022] Step 1: Build side cut-off ditches 2 at the slope toe of side cut-off 1 in the open-pit stope, lead the intercepted water directly to the drainage tank pool 6, set up multiple cut-off ditches to reduce the amount of water flowing into the bottom of the pit, and relieve the buoyancy tank at the bottom of the pit Suction pump 5 pressure.

[0023] Step 2: The bottom of the open-air pit includes the upper shallow sedimentation water 4 and the bottom sedimentation silt 3. A floating tank drainage pump 5 is arranged from the deep water area of the mining pit with a relatively shallow a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com