Non-pressure-loss type range hood air outlet system for multi-lampblack treatment

A technology for oil fume treatment and hoods, which is applied in the direction of oil fume removal, household heating, heating methods, etc., and can solve problems that affect the overall performance of hoods and human hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

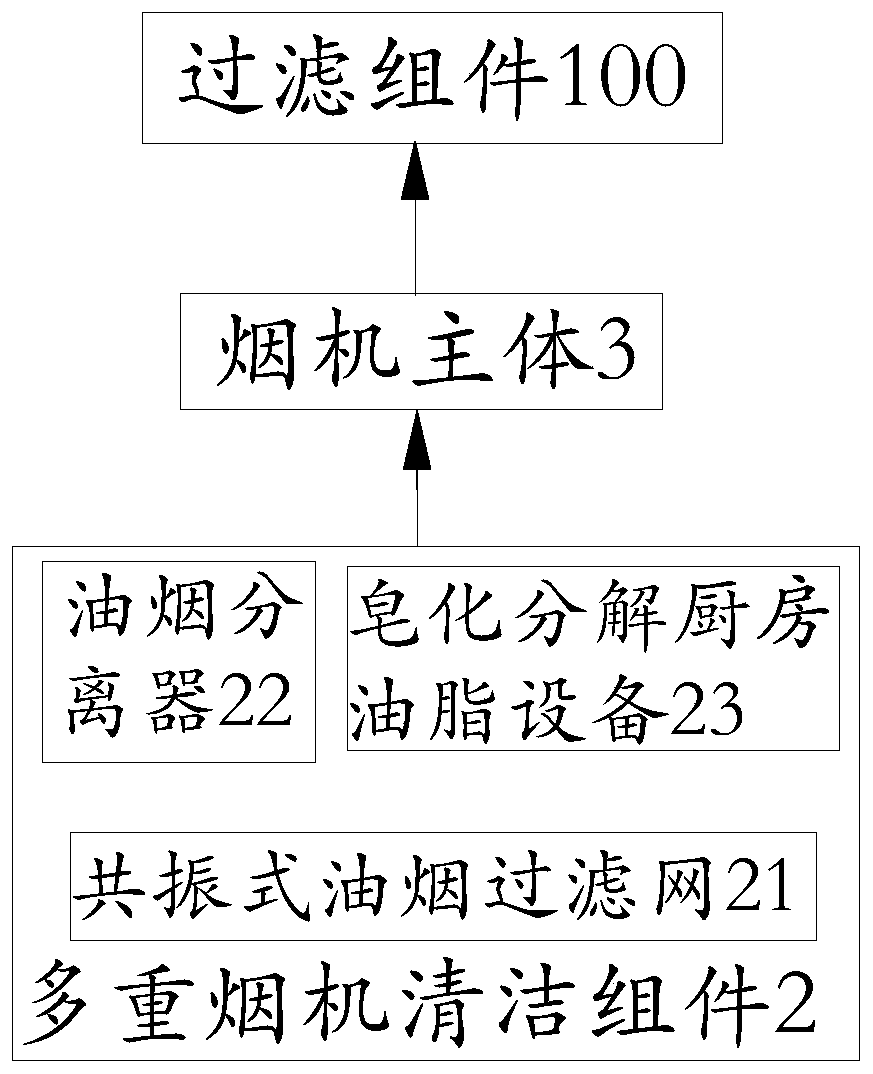

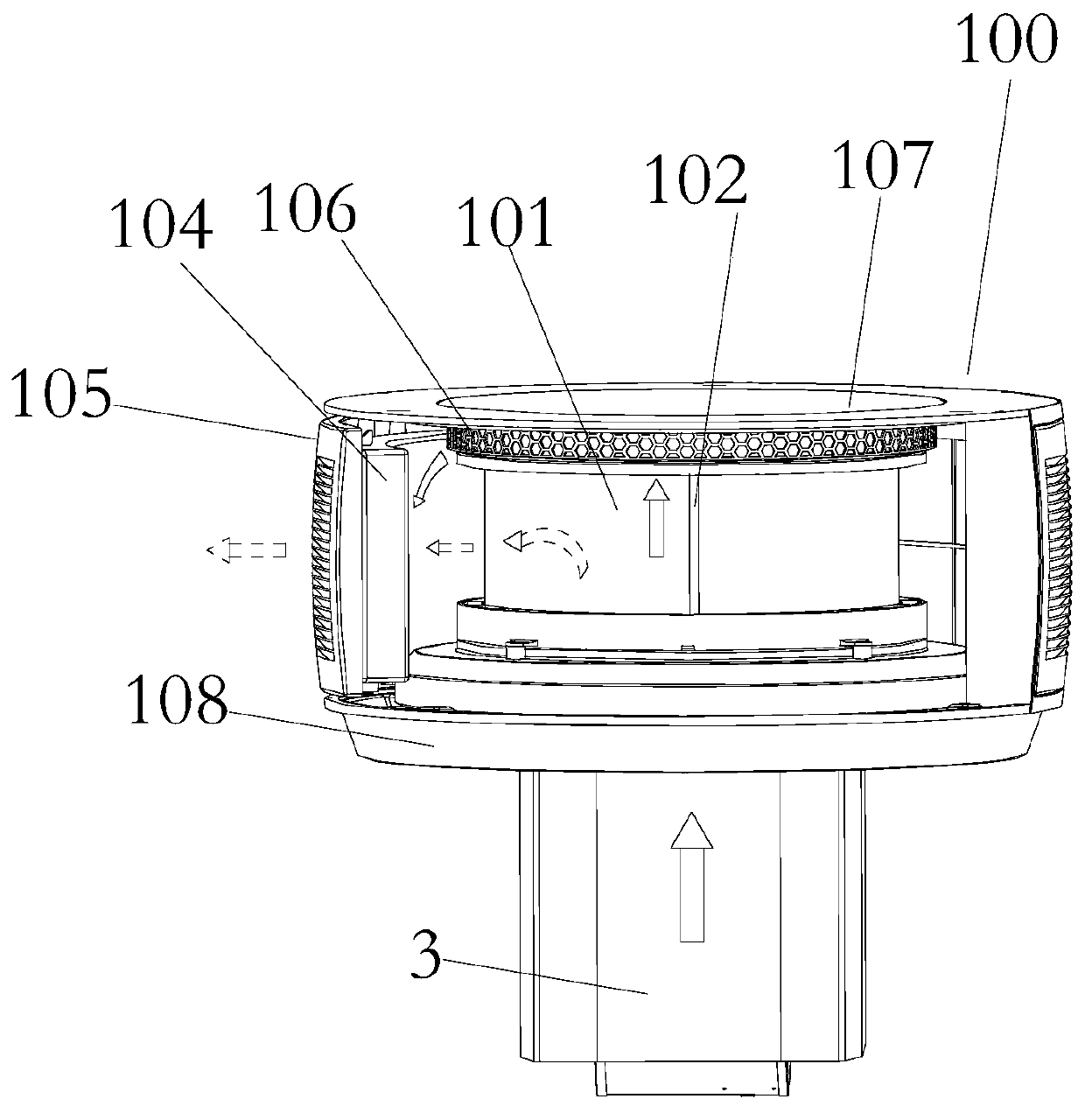

[0086] A non-pressure loss hood air outlet system with multiple cooking fume treatment, such as Figure 1 to Figure 2 As shown, a hood main body 3 , multiple hood cleaning components 2 and a filter component 100 are provided. The filter component is arranged at the hood air outlet of the hood main body 3 .

[0087] In this embodiment, the multi-hood cleaning assembly 2 is set as a combination of a resonant oil fume filter 21, an oil fume separator 21, and a saponification and decomposition kitchen grease equipment 23.

[0088] Specifically, the resonant oil fume filter 21 is provided with a non-planar filter device 211 for filtering oil fume, and a resonant body 212 with elastic potential energy. The minimum elastic potential energy of the piece>0; one end of the elastic piece is fixed to the fixed frame on the fixed body, the above-mentioned air inlet surface 2122 is at least one of planar or non-planar structures, and any one of the air inlet surfaces 2122 and The other ad...

Embodiment 2

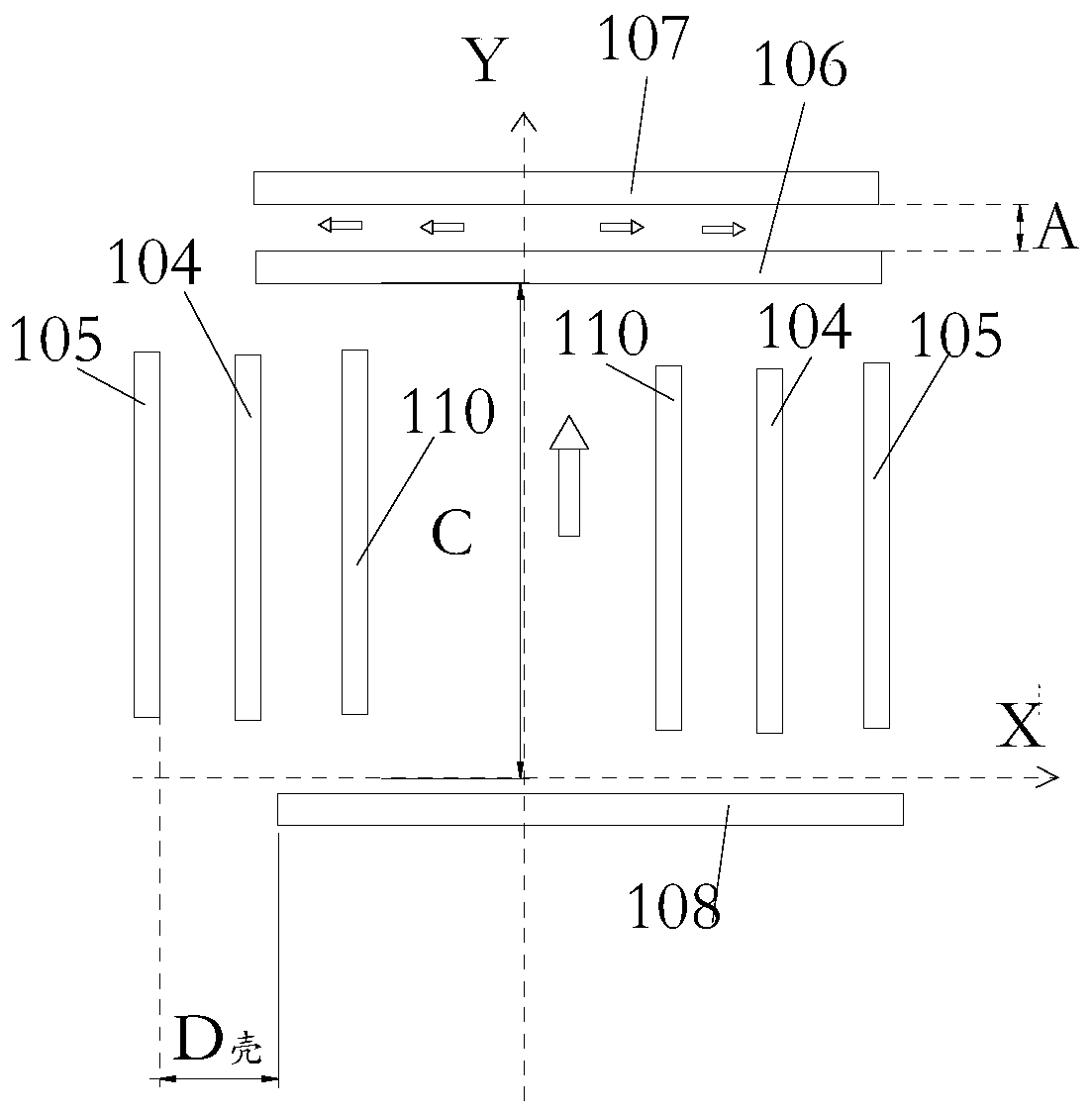

[0117] A non-pressure-loss type hood air outlet system for multiple oil fume treatment, other structures are the same as in Embodiment 1, the difference is that the non-pressure loss type hood air outlet system for multiple oil fume treatment, such as Figure 10 As shown, the filter layer 110 is provided with a gauze 101 .

[0118] Specifically, the relative distance between the gauze 101 and the activated carbon layer 104 along the X-axis direction is B;

[0119] 0mm≤B≤600mm;

[0120] Specifically, the thickness E of gauze 101 纱 ;0.2mm≤E 纱 ≤60mm;

[0121] Specifically, the gauze 101 is set as a single-layer gauze 101

[0122] Specifically, the gauze 101 is provided with ventilation holes, and the ventilation holes are set as any one or more of polygonal ventilation holes, rectangular ventilation holes, circular ventilation holes or oval ventilation holes;

[0123] Specifically, the area of the vent hole is S 孔 ;1mm 2 ≤S 孔 ≤2500mm 2 ;

[0124] By setting the gauze ...

Embodiment 3

[0126] A non-pressure-loss hood air outlet system for multiple oil fume treatment, other structures are the same as those in Embodiment 1 or 2, the difference is that, as Figure 11 As shown, the filter layer 110 is provided with gauze 101 and HEPA net 103;

[0127] Specifically, the gauze 101 and the HEPA net 103 are arranged sequentially along the X-axis of the first plane starting from the origin;

[0128] The gauze 101 and the HEPA net 103 provided through the filter layer 110 can further improve the filtration of harmful substances in the oil fume flow out from both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com