Electromagnetic detecting method for detecting defects in thin metal foil

An electromagnetic detection and metal foil technology, applied in the direction of material magnetic variables, etc., can solve the problems of slow speed, inability to realize real-time online monitoring, low efficiency, etc., and achieve the effect of high measurement efficiency, real-time detection and feedback, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

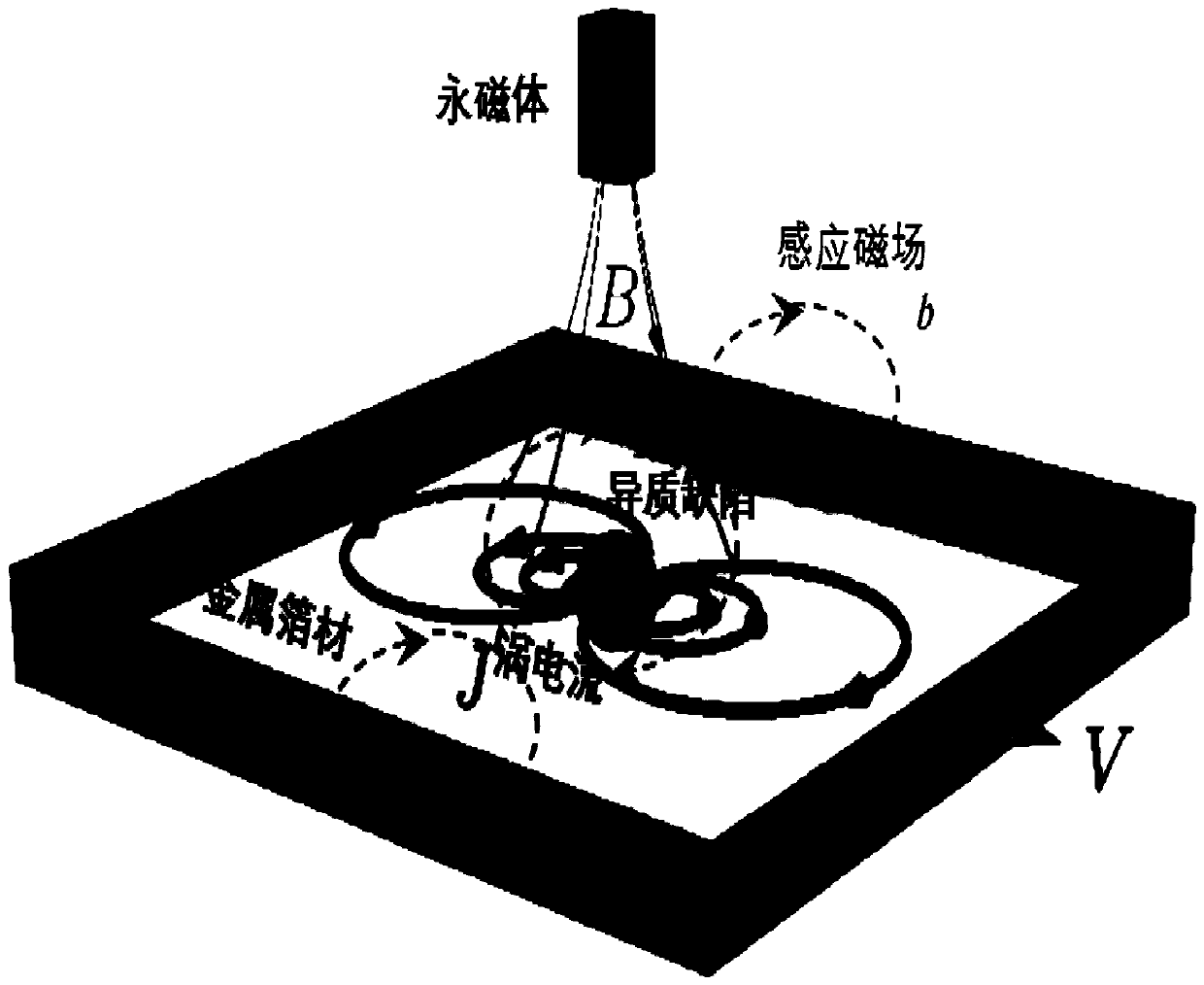

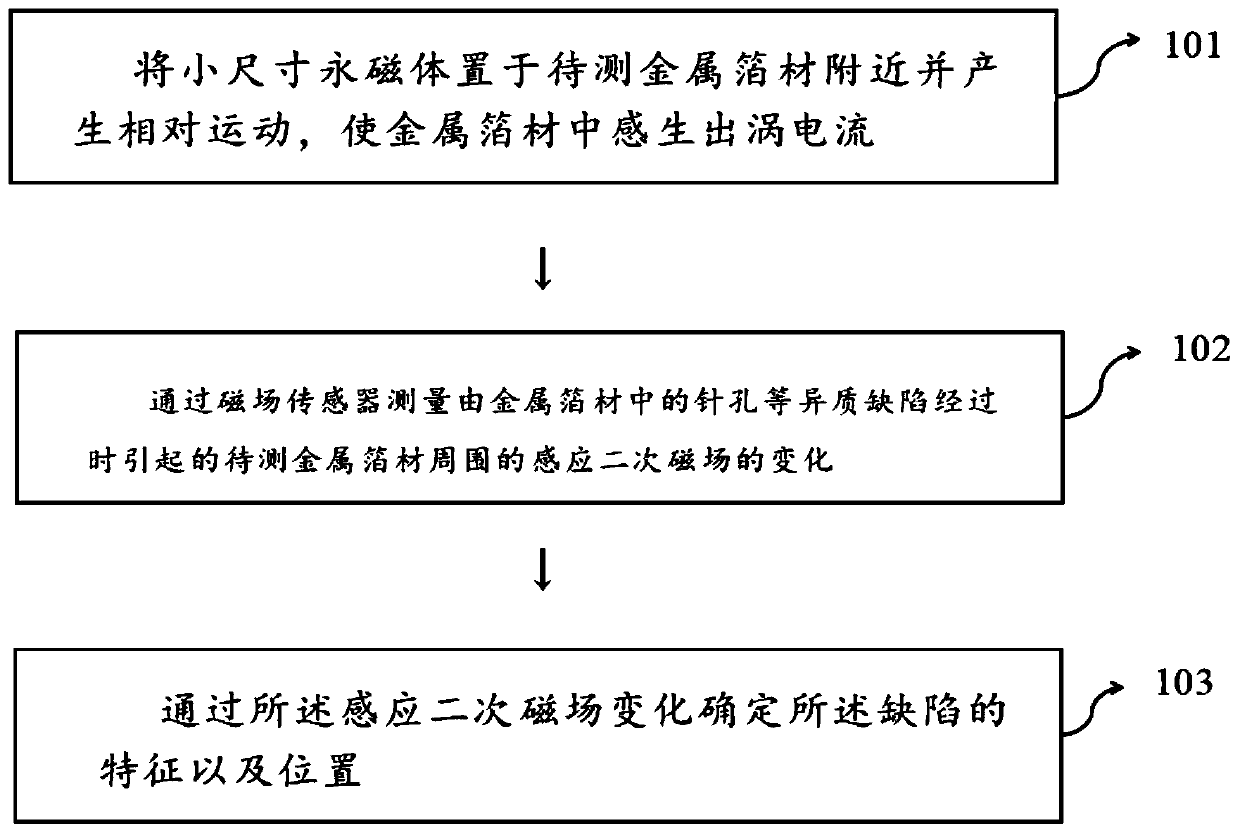

[0020] Basic principle of the present invention is as follows: as figure 1 As shown, a local static magnetic field B is provided by a small-sized permanent magnet, and an electromagnetic sensitive area is established in the metal foil. The range is about three times the size of the small magnet, and all changes in electromagnetic parameters are mainly concentrated in this sensitive area. Make relative movement between the small permanent magnet and the metal foil sample to be tested, and according to Ohm's law, a pair of eddy current rings J with opposite current directions are generated in the metal foil. According to Ampere's law, the eddy current induces a secondary magnetic field b around it.

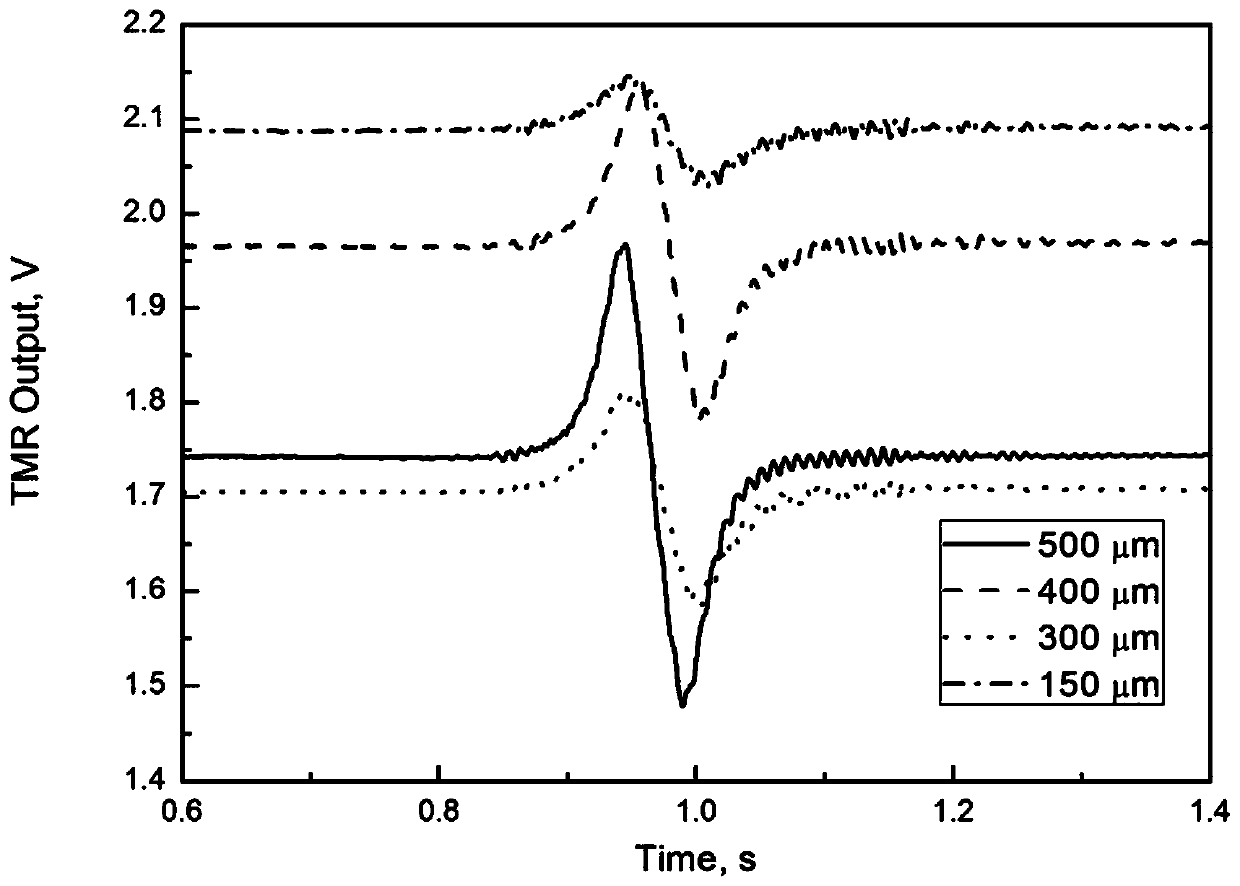

[0021] When heterogeneous defects such as pinholes enter the electromagnetic sensitive area with the movement of the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com