Low-density self-forming graphite adsorption material as well as preparing and recycling method thereof

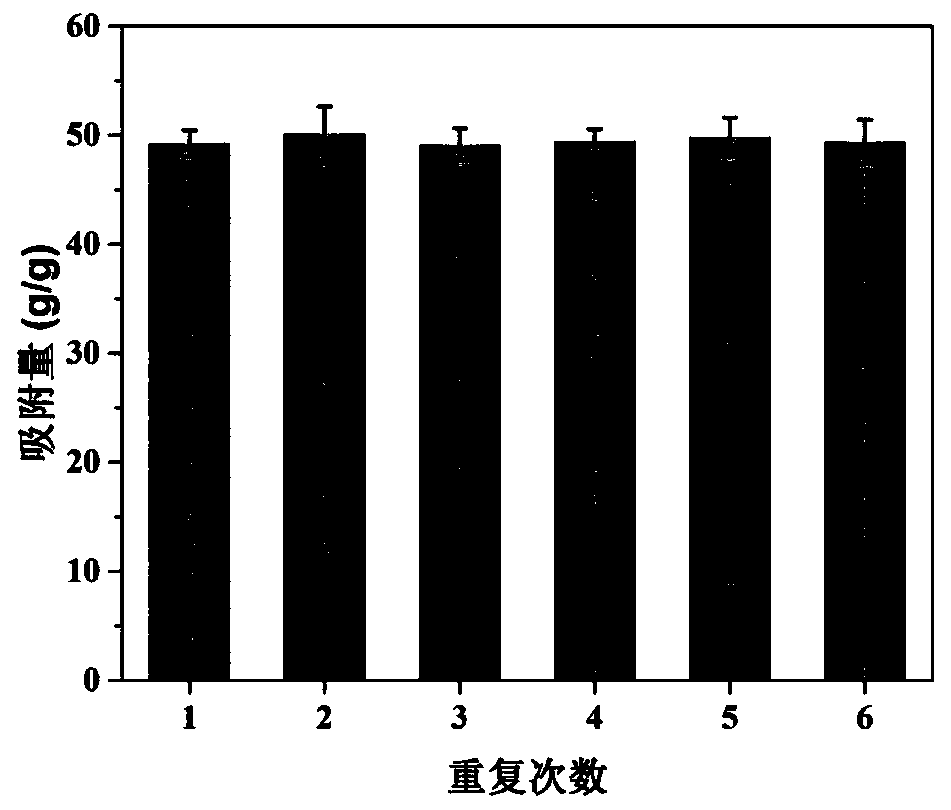

An adsorption material and self-forming technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve problems such as poor regeneration performance, reduced adsorption performance, and difficult operation of expanded graphite particles, and achieve simple regeneration and recycling , the effect of avoiding environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

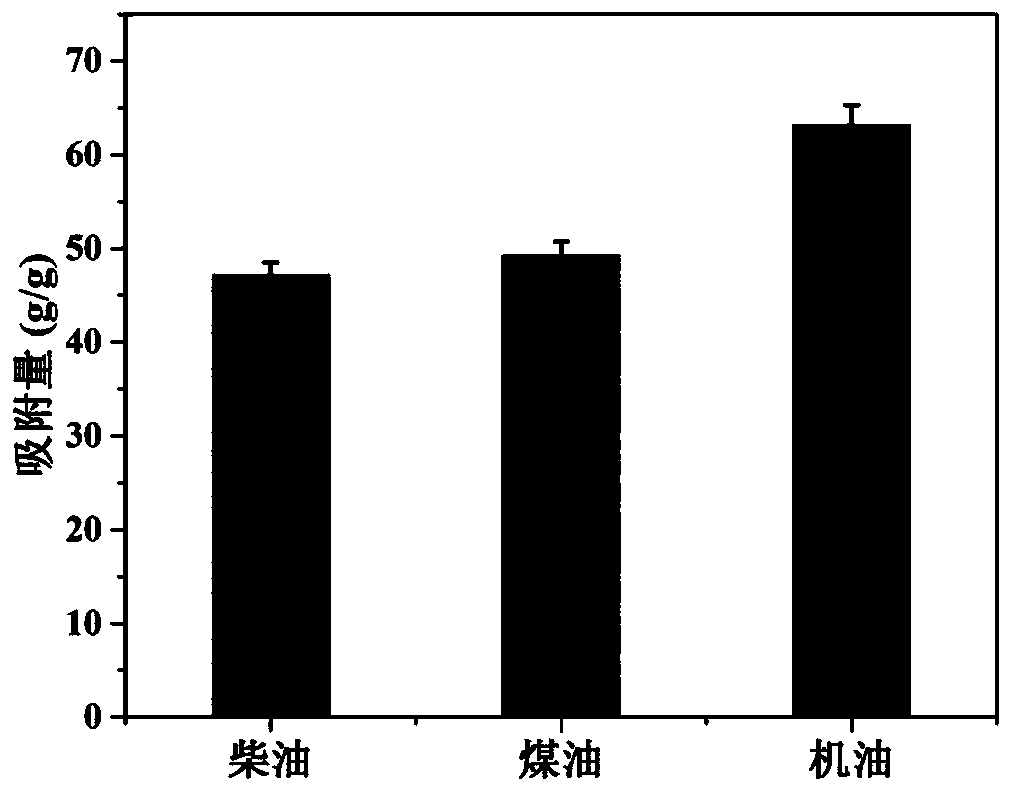

Examples

Embodiment 1

[0026] Add natural flake graphite (50 mesh) and concentrated sulfuric acid (98%) into the reaction kettle according to the ratio of graphite (kg): concentrated sulfuric acid (L) = 1:10, the ambient temperature is 8°C, stir well and press hydrogen peroxide (L) : The ratio of concentrated sulfuric acid (L)=1:5 was slowly added to hydrogen peroxide (30%), and after stirring for 5 minutes, a uniformly mixed reactant was obtained.

[0027] Transfer 1000 g of the homogeneously mixed reactants prepared according to the above proportions to a cuboid container (5cm×5cm×20cm), and let it stand at room temperature for 3 hours to obtain a self-forming expanded graphite molded body. The obtained expanded graphite molded body was dried in a drying oven at 350° C. for 1 hour, and the sulfur content of the treated expanded graphite was measured to be 0.04%. The expanded graphite molded body after drying is taken out, and its density is 0.1g / cm 3 .

Embodiment 2

[0029] Transfer 15 g of the homogeneously mixed reactants prepared according to the ratio of Example 1 to a spherical container (5 cm in diameter), and let stand at room temperature for 3 hours to obtain a self-forming expanded graphite molded body. The expanded graphite molded body was dried in a drying kiln at 380° C. for 1 hour, and the sulfur content of the treated expanded graphite was measured to be 0.02%. The expanded graphite molded body after drying is taken out, and its density is 0.01g / cm 3 .

Embodiment 3

[0031] Transfer 40 g of the homogeneously mixed reactants prepared according to the ratio of Example 1 to a cylindrical container (inner diameter 5 cm, height 20 cm), and place it at room temperature for 4 h to obtain a self-forming expanded graphite molded body. The expanded graphite molded body was dried in a drying kiln at 380° C. for 1 hour, and the sulfur content of the treated expanded graphite was measured to be 0.02%. The expanded graphite molded body after drying is taken out, and its density is 0.005g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com