Magnetite crushing, pre-separating and mineral milling process

A magnetite and process technology, applied in the field of magnetite crushing-pre-selection-grinding process, can solve the problems of high production and operation costs, high investment in equipment and machine infrastructure, dust and noise pollution, etc., and achieve simplified crushing and grinding process, Significant economic benefits and the effect of saving infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

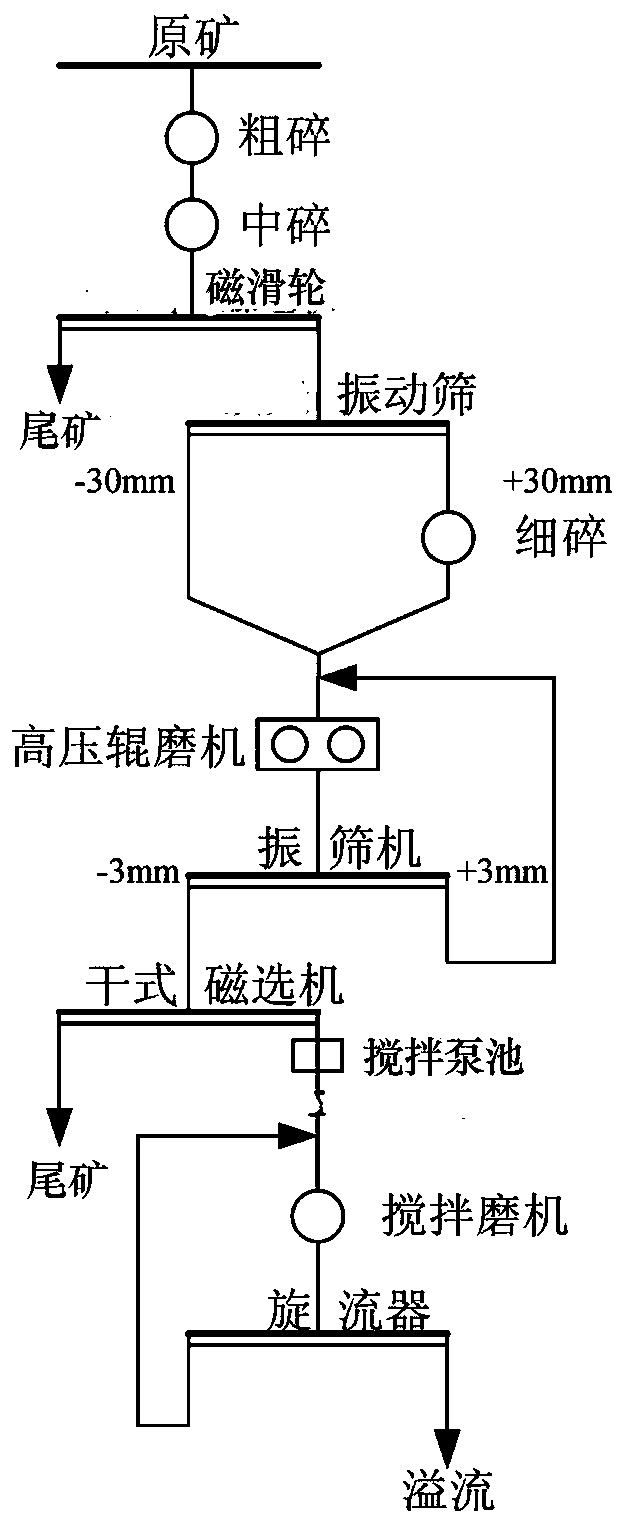

[0028] Such as figure 1 Shown: a kind of magnetite crushing-preselection-grinding process of the present invention, this process comprises: crushing dry separation operation, described crushing dry separation operation process is as follows: the particle size is 1000mm~0mm, grade is 25.85% The magnetite raw ore is crushed by primary crusher and secondary crusher in open circuit, and the secondary crushed product is dry-separated by magnetic pulley to obtain dry-separated concentrate with a grade of 28.86% and dry-separated tailings with a grade of 7.56% and a yield of 14.13%. , dry separation tailings are discarded, dry separation concentrate is fed into the pre-screening vibrating screen, +30mm on-screen products are fed into the open-circuit fine crusher, and -30mm under-screen products and finely crushed products are combined into broken dry separation operation prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com