Sand-blasting-free aluminum plate surface die pressing equipment

An aluminum plate and sandblasting technology, applied in decorative arts, embossed ornaments and other directions, can solve the problems of waste of resources, high process cost, and sand cannot be recycled, and achieve the effect of saving costs and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

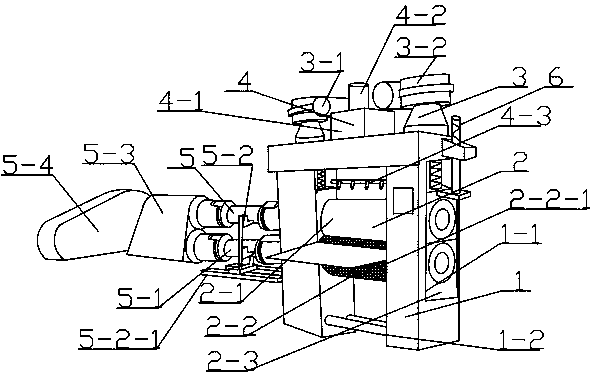

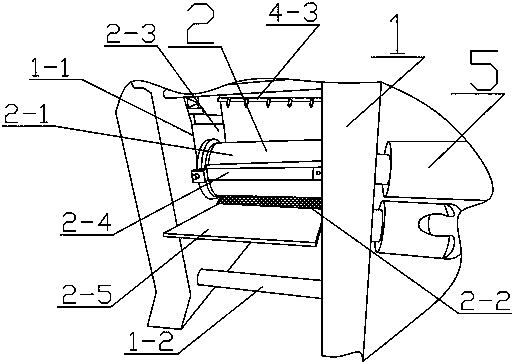

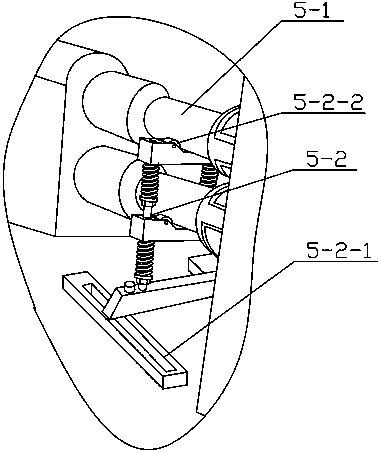

[0017] Such as figure 1 , 2 , 3, a sandblasting-free aluminum plate surface molding equipment, including a frame 1, a rolling device 2, a lifting device 3, a cooling device 4, a transmission device 5, the frame 1 is an inverted U shape, which passes through The bolts are fixedly connected to the ground, and the two sides of the frame 1 are provided with installation grooves 1-1, and the installation groove 1-1 is provided with a rolling device 2, and the rolling device 2 consists of pressure roller 1 2-1 and pressure roller 2 2-2 The two ends of pressure roller 1 2-1 and pressure roller 2-2 are provided with slider 2-3, and the slider 2-3 is installed in cooperation with the installation groove 1-1, and the sliders at both ends of pressure roller 2-1 2-3 is connected with the lifting device 3 through the screw rod, and one end of the pressure roller 2-1 and the pressure roller 2-2 is respectively connected with the transmission device 5 flexibly, and the rear of the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com