Preparation method of 2, 6-dichloromethylpyridine hydrochloride

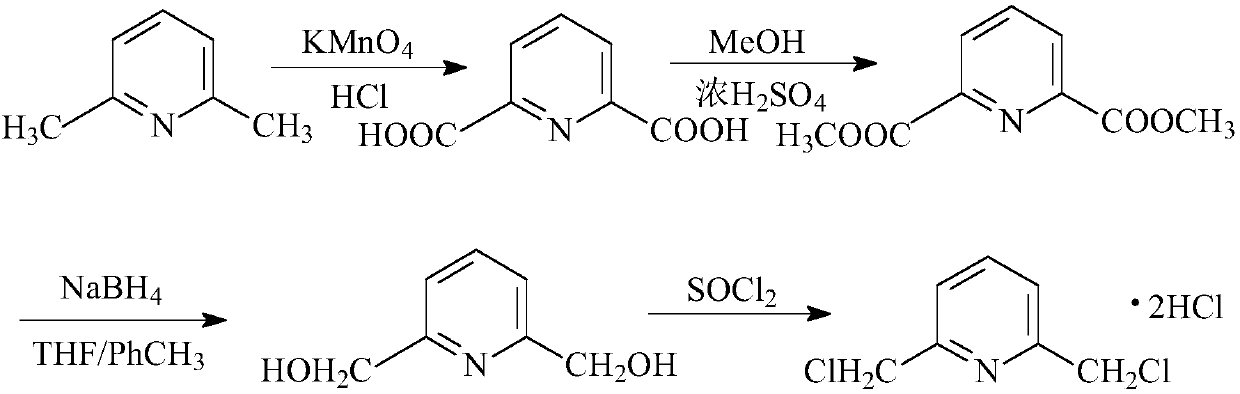

A technology of dichloropicoline hydrochloride and lutidine, applied in the field of preparation of 2,6-dichloropicoline hydrochloride, can solve the problems of short cost route, high toxicity of raw materials, high cost, etc. Achieve the effect of low cost, few reaction steps and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 2,6-lutidine (21.4g, 0.2mol) and 150ml of water into a 250ml flask, heat to 80°C, add potassium permanganate (126.4g, 0.8mol) in batches, and maintain the temperature Heating and stirring at 75-80°C for 35 minutes, followed by thin-layer chromatography analysis, after the reaction is complete, use 2mol / l hydrochloric acid to adjust the pH value of the reaction solution to 3, and cool the temperature of the reaction solution to 20°C to obtain 2,6-pyridinedicarboxylic acid .

[0023] (2) 2,6-pyridinedicarboxylic acid and methanol (16g, 0.5mol) were reacted with concentrated sulfuric acid to generate 2,6-pyridinedicarboxylic acid dimethyl ester.

[0024] (3) Dimethyl 2,6-pyridinedicarboxylate was dissolved in a solvent mixed with 75mlTHF and 75ml toluene, and sodium borohydride (45.4g, 1.2mol) and aluminum trichloride were added in batches at 0-5°C, and The reaction was continued for 3-4 hours, followed by thin-layer chromatography analysis until the reaction was ...

Embodiment 2

[0027] (1) Add 2,6-lutidine (21.4g, 0.2mol) and 150ml of water into a 250ml flask, heat to 80°C, add potassium permanganate (142.2g, 0.9mol) in batches, and maintain the temperature Heating and stirring at 75-80°C for 35min, followed by thin-layer chromatography analysis, after the reaction is complete, use 2mol / l hydrochloric acid to adjust the pH value of the reaction solution to 4, and cool the temperature of the reaction solution to 25°C to obtain 2,6-pyridinedicarboxylic acid .

[0028] (2) 2,6-pyridinedicarboxylic acid and methanol (17.9g, 0.56mol) were reacted with concentrated sulfuric acid to generate 2,6-pyridinedicarboxylic acid dimethyl ester.

[0029] (3) Dimethyl 2,6-pyridinedicarboxylate was dissolved in a solvent mixed with 75mlTHF and 75ml toluene, and sodium borohydride (53g, 1.4mol) and aluminum trichloride were added in batches at 0-5°C, and the addition was completed The reaction was continued for 3-4h, followed by thin-layer chromatography analysis until...

Embodiment 3

[0032] (1) Add 2,6-lutidine (21.4g, 0.2mol) and 150ml of water into a 250ml flask, heat to 80°C, add potassium permanganate (15.8g, 1.0mol) in batches, and maintain the temperature Heating and stirring at 75-80°C for 35 minutes, followed by thin-layer chromatography analysis, after the reaction is complete, use 2mol / l hydrochloric acid to adjust the pH value of the reaction solution to 3, and cool the temperature of the reaction solution to 25°C to obtain 2,6-pyridinedicarboxylic acid .

[0033] (2) 2,6-pyridinedicarboxylic acid and methanol (19.2g, 0.6mol) were reacted with concentrated sulfuric acid to generate 2,6-pyridinedicarboxylic acid dimethyl ester.

[0034] (3) Dimethyl 2,6-pyridinedicarboxylate was dissolved in a solvent mixed with 75mlTHF and 75ml toluene, and sodium borohydride (68.1g, 1.8mol) and aluminum trichloride were added in batches at 0-5°C, and The reaction was continued for 3-4 hours, followed by thin-layer chromatography analysis until the reaction was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com