Halogen-free low-smoke rubber-sheathed flexible cable for marine wind power generation and preparation process thereof

A preparation process and technology of flexible cables, applied in power cables, cable/conductor manufacturing, insulated cables, etc., can solve the problems of inability to meet the large-angle yaw requirements and low torsion requirements of large offshore wind turbines, and achieve good aging resistance and Ozone resistance, resistance to corrosion by hydraulic and gear oils, the effect of a simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

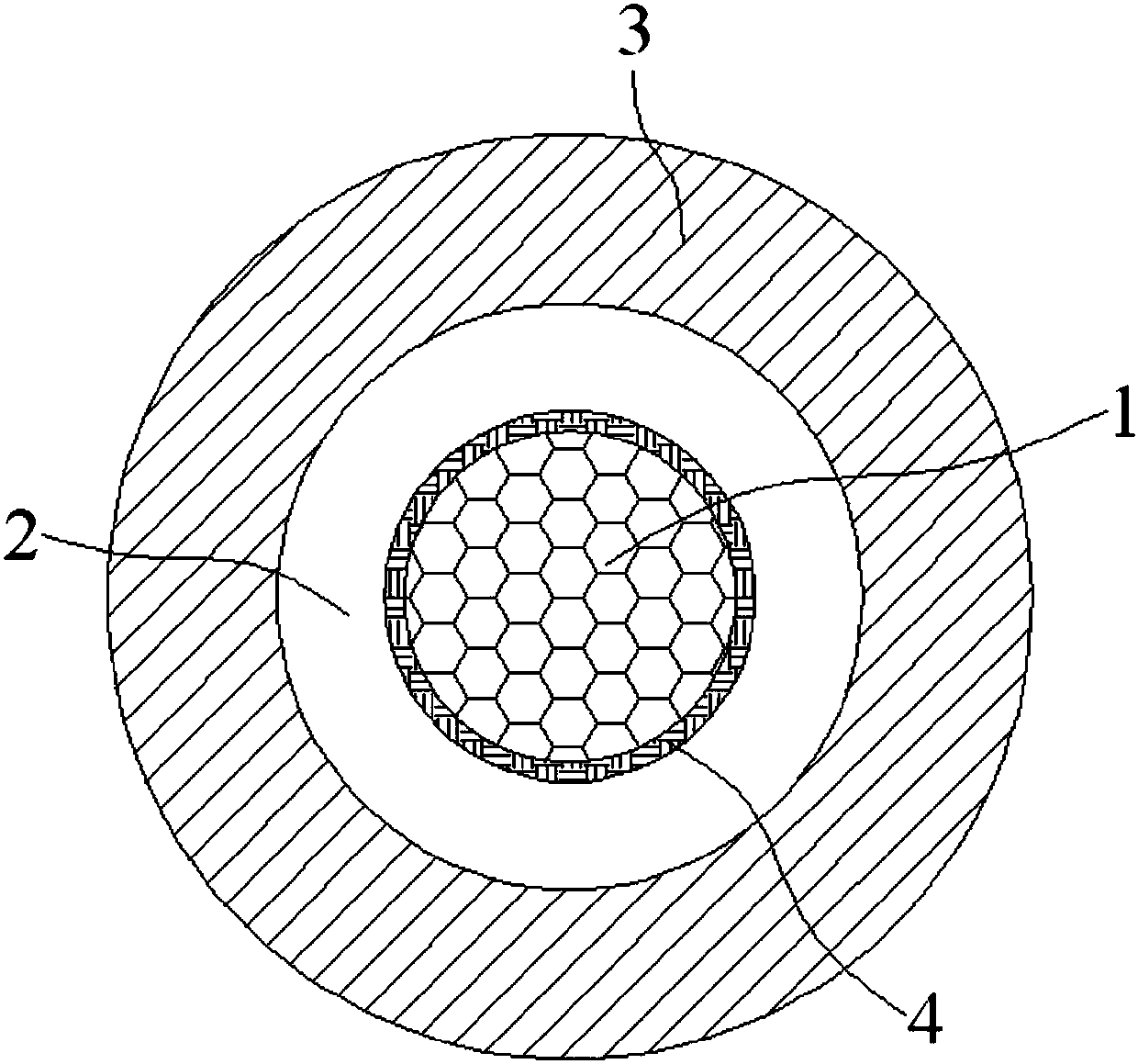

[0031] Embodiments 1 to 4: A halogen-free low-smoke rubber-sheathed flexible cable for offshore wind power generation, including a copper conductor 1 located in the center, and the outer surface of the copper conductor 1 is covered with an ethylene-propylene rubber insulating layer 2. The ethylene-propylene rubber The outer surface of the insulating layer 2 is covered with a 110°C halogen-free low-smoke polyolefin rubber sheath layer 3;

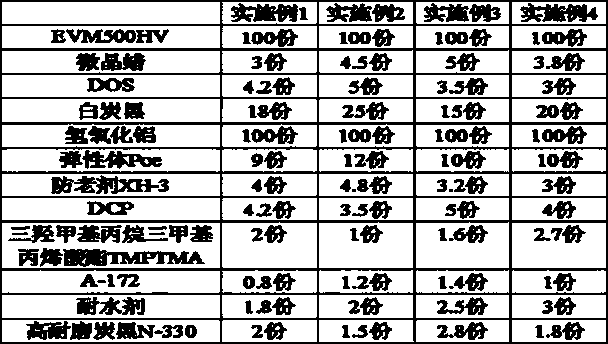

[0032] The ethylene-propylene rubber insulating layer 2 is composed of the following components by weight, as shown in Table 1:

[0033] Table 1

[0034]

[0035] The 110°C halogen-free low-smoke polyolefin rubber sheath layer 3 in the above-mentioned halogen-free low-smoke rubber-sheathed flexible cable for offshore wind power generation is obtained by the following steps:

[0036] Step 1. Knead the EVM500HV and the elastomer Poe in an internal mixer at 40°C-50°C for 5min-6min, and knead evenly.

[0037] Step 2, add the microcrystalline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com