Selective extraction and separation method for trivalent actinides and lanthanides in spent fuel reprocessing

A separation method and technology for spent fuel, which are applied in the field of selective extraction and separation of trivalent actinides and lanthanides in spent fuel, can solve the problem that a multi-stage extraction and separation system has not been developed, the stability of the extractant is poor, and the extraction kinetics performance is poor. In order to achieve good extraction kinetic performance, simplify the composition of the extraction system, and improve the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

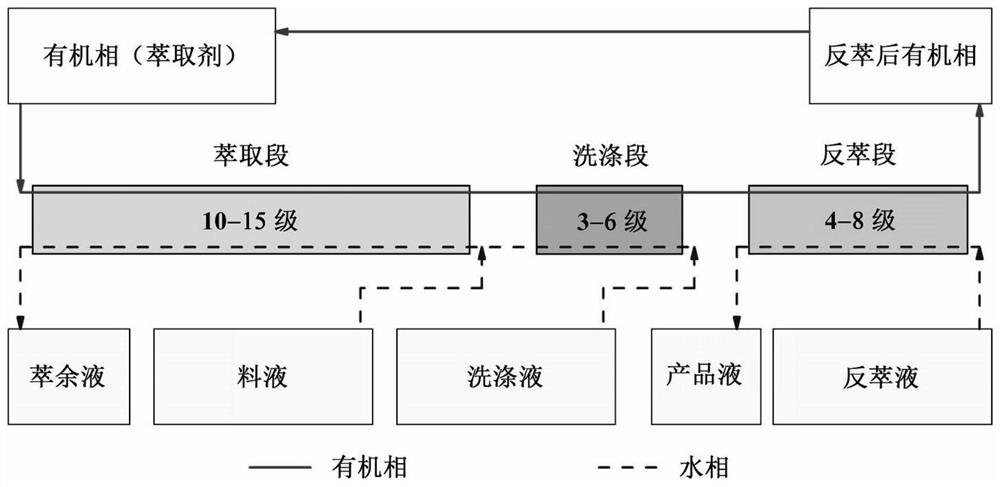

Method used

Image

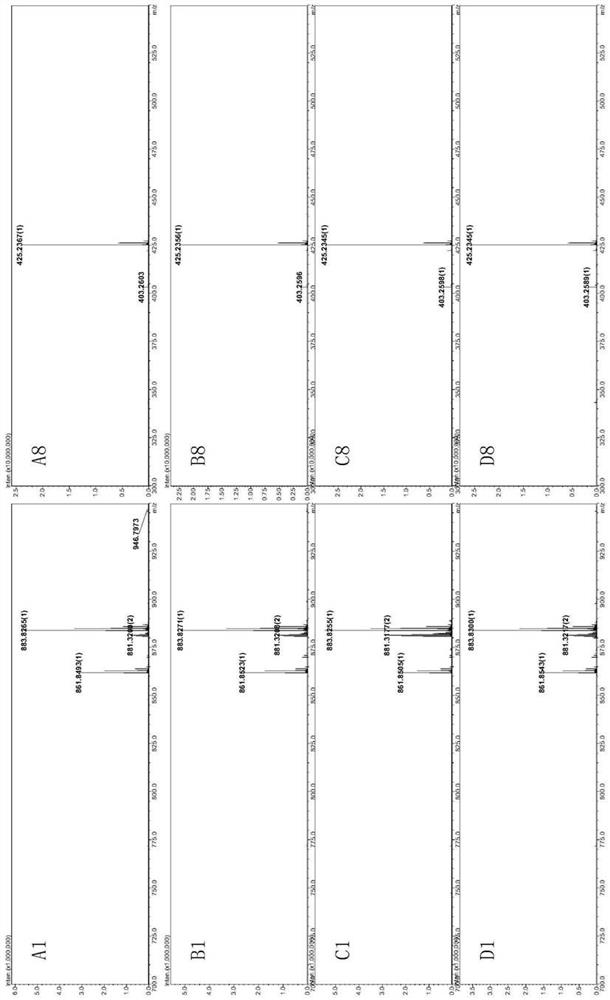

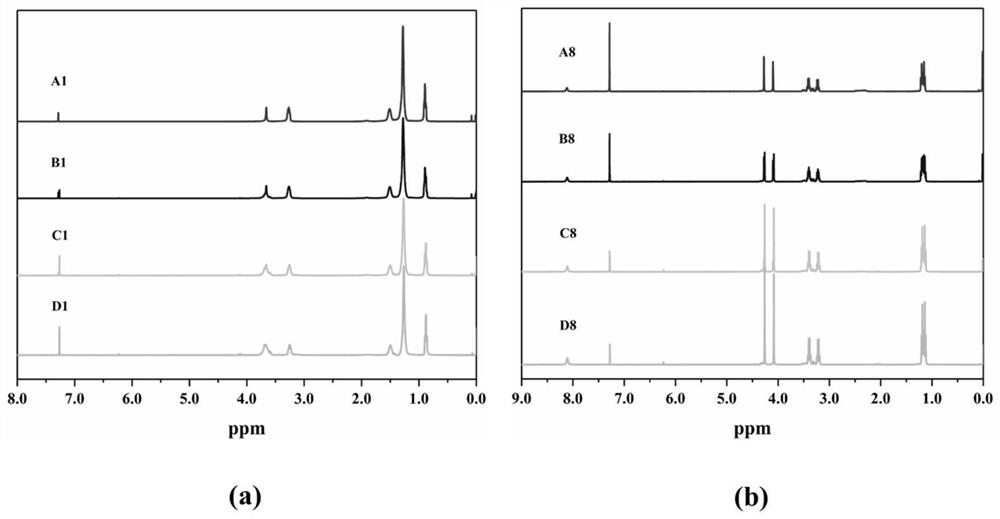

Examples

Embodiment 1-6

[0044] The detergent TEE-BisDGA adopted is prepared by the following method:

[0045] (1) Diglycolic anhydride (2.9g, 0.025mol) was added to 40mL of tetrahydrofuran, and placed in an ice-water bath at 0°C, and diethylamine (1.8g, 0.025mol) was added dropwise while stirring. After the addition was complete, remove In an ice-water bath, react at 25°C for 3 hours under stirring conditions; then rotary steam the product obtained from the reaction to remove tetrahydrofuran, and then add dropwise an aqueous solution of hydrochloric acid with a volume concentration of 50% to the product obtained from the reaction of removing tetrahydrofuran, and white crystals are precipitated. Suction filtration, and recrystallization and purification using a mixed solvent of methanol / water with a volume ratio of 1:1 to obtain N,N-diethyl-3-oxoglutaric acid as a white flaky solid;

[0046] (2) Under stirring conditions, N,N-diethyl-3-oxoglutaric acid (4.7g, 0.025mol), ethylenediamine (0.7g, 0.010mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com