Method for selectively extracting scandium from laterite-nickel ore

A lateritic nickel ore and selective technology, applied in the field of metallurgical engineering, can solve the problems of high impurities, and achieve the effects of simple operating conditions, clean and efficient extraction, high-value preparation, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The composition of laterite nickel ore to be treated in this embodiment is: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc 0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.% and Cr1.23wt.%.

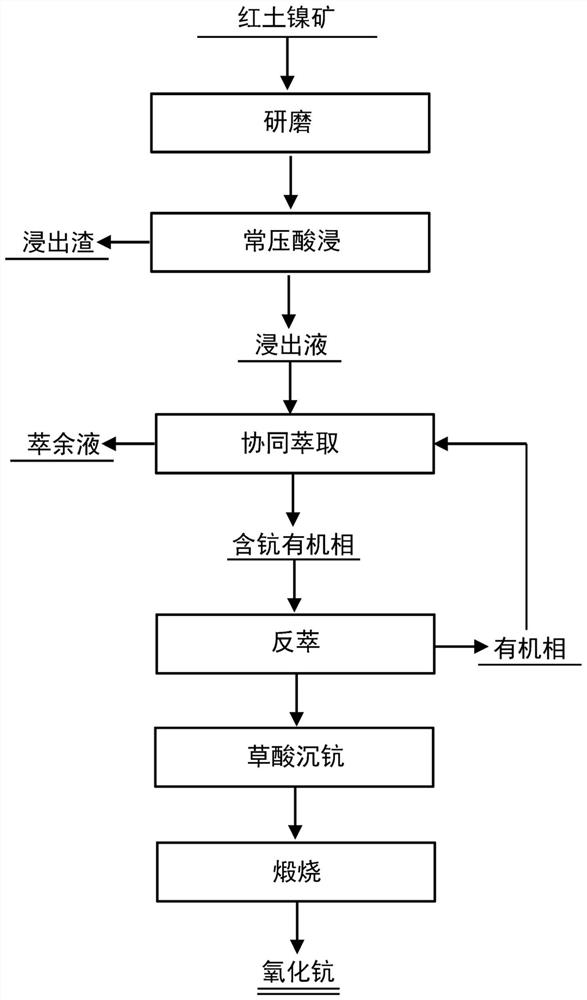

[0033] The method for selectively extracting scandium from laterite nickel ore of the present embodiment, the technological process is as follows figure 1 shown, including the following steps:

[0034] (1) Crushing and grinding the laterite nickel ore to obtain a laterite nickel ore with a particle size of -0.074mm;

[0035] (2) Put the finely ground laterite nickel ore in step (1) in 3.0mol / L sulfuric acid solution for atmospheric pressure acid leaching, the leaching time is 3.0h, the leaching temperature is 80°C, the leaching liquid-solid ratio is 5, and the ratio range mL / g, filter after leaching to obtain leaching solution and leaching residue. During this process, the leaching rates of Ni, Co, Mn, Sc, Fe, Mg, Al and Cr were 76.76%, 71.7%, 86.87%, 84.27% , 72.14%, 67.19%, 71.72% a...

Embodiment 2

[0041] The composition of laterite nickel ore to be treated in this embodiment is: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc 0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.% and Cr1.23wt.%.

[0042] The method for selectively extracting scandium from laterite nickel ore of the present embodiment, the technological process is as follows figure 1 shown, including the following steps:

[0043] (1) Crushing and grinding the laterite nickel ore to obtain a laterite nickel ore with a particle size of -0.074mm;

[0044] (2) Place the laterite nickel ore obtained in step (1) in 2.0mol / L sulfuric acid solution for atmospheric pressure acid leaching, the leaching time is 5.0h, the leaching temperature is 90°C, the leaching liquid-solid ratio is 7, and the ratio unit is mL / g, to obtain leachate and leach residue after filtration, the leaching rates of Ni, Co, Mn, Sc, Fe, Mg, Al and Cr in this process were 68.34%, 62.45%, 78.64%, 80.62%, 60.74%, 55.93% respectively %, 64.49% and 34.7...

Embodiment 3

[0050] The lateritic nickel ore to be treated in the present embodiment consists of: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.%, Cr 1.23wt.%.

[0051] The method for selectively extracting scandium from laterite nickel ore of the present embodiment, the technological process is as follows figure 1 shown, including the following steps:

[0052] (1) Crushing and grinding the laterite nickel ore to be processed to obtain laterite nickel ore with a particle size of -0.074mm.

[0053] (2) Place the laterite nickel ore obtained in step (1) in 3.0mol / L sulfuric acid solution for atmospheric pressure acid leaching, the leaching time is 2.0h, the leaching temperature is 80°C, the leaching liquid-solid ratio is 3, and the ratio unit is mL / g, filtered after the leaching is completed, to obtain the leaching solution and leaching residue, the leaching rates of Ni, Co, Mn, Sc, Fe, Mg, Al and Cr in this process were 70.43%, 70.08%, 81.17%, 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com