Preparation method and application of shredded tea leaves to preparation of tea cigarette cartridge

A technology of shredded tea and tea leaves, which is applied in the fields of tobacco preparation, application, smoker’s supplies, etc. It can solve the problems of poor smoking experience, poor smoking refreshing effect, large smoke, etc., and achieve high smoking score, improving refreshing effect, and reducing lignin The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is a specific embodiment for preparing product 1.

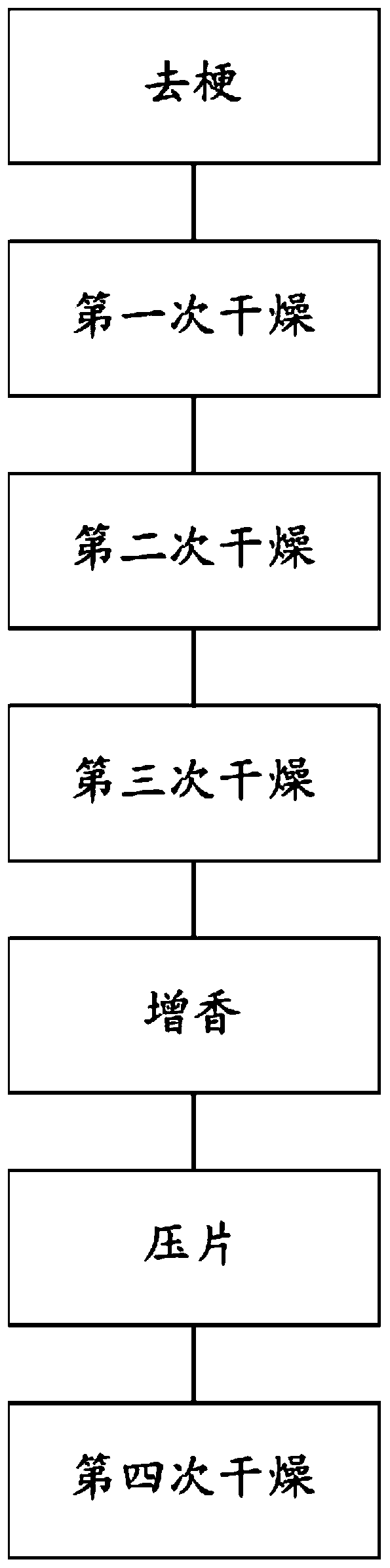

[0030] Fresh tea leaves were destemmed to obtain the first product 1; the first product 1 was dried at 60°C for 30 minutes until the water content was reduced by 30%, and the second product 1 was obtained; the second product 1 was dried at 85°C for 70 minutes and dried until the water content was reduced by 20% %, to obtain the third product 1; the third product 1 was dried at 100° C. for 80 minutes, dried until the water content was reduced by 10%, and then allowed to stand at room temperature, and the surface of the standing product was sprayed with tea extract 1 to obtain the fourth product 1; The fourth product 1 was crushed into granules with a particle size of 25-35 meshes and then pressed into tablets to obtain the fifth product 1 with a diameter of 15-50 mm; the fifth product 1 was dried at 110°C for 120 minutes to obtain a product with a water content of 5%-15% 1.

[0031] In this embodiment, ...

Embodiment 2

[0033] This embodiment is a specific embodiment for preparing product 2.

[0034] Fresh tea leaves were destemmed to obtain the first product 2; the first product 2 was dried at 65°C for 60 minutes until the water content was reduced by 30%, and the second product 2 was obtained; the second product 2 was dried at 90°C for 40 minutes and dried until the water content was reduced by 20% %, to obtain the third product 2; the third product 2 was dried at 80° C. for 50 minutes, dried until the water content was reduced by 10%, and then allowed to stand at room temperature, and the tea extract 2 was sprayed on the surface of the standing product to obtain the fourth product 2; The fourth product 2 was crushed into particles with a particle size of 25-35 meshes and then pressed into tablets to obtain the fifth product 2 with a diameter of 15-50 mm; the fifth product 2 was dried at 120°C for 60 minutes to obtain a product 2 with a water content of 5%-15%. .

[0035] In this embodimen...

Embodiment 3

[0037] This embodiment is a specific embodiment for preparing product 3.

[0038] Fresh tea leaves were destemmed to obtain the first product 3; the first product 3 was dried at 80°C for 35 minutes until the water content was reduced by 30%, and the second product 3 was obtained; the second product 3 was dried at 70°C for 50 minutes and dried until the water content was reduced by 20% %, to obtain the third product 3; the third product 3 was dried at 85° C. for 70 minutes, dried until the water content was reduced by 10%, and then allowed to stand at room temperature, and the tea extract 3 was sprayed on the surface of the standing product to obtain the fourth product 3; The fourth product 3 was crushed into particles with a particle size of 25-35 meshes and then pressed into tablets to obtain the fifth product 3 with a diameter of 15-50 mm; the fifth product 3 was dried at 90°C for 90 minutes to obtain a product 3 with a water content of 5%-15%. .

[0039] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com