Connecting shackle and manufacturing equipment and manufacturing method thereof

A chain buckle and manufacturing device technology, which is applied in the chain buckle and its manufacturing equipment and manufacturing field, can solve the problems of very high precision requirements, complicated procedures, and the inability to manufacture small and heavy chain buckles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further understand the features, technical means and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

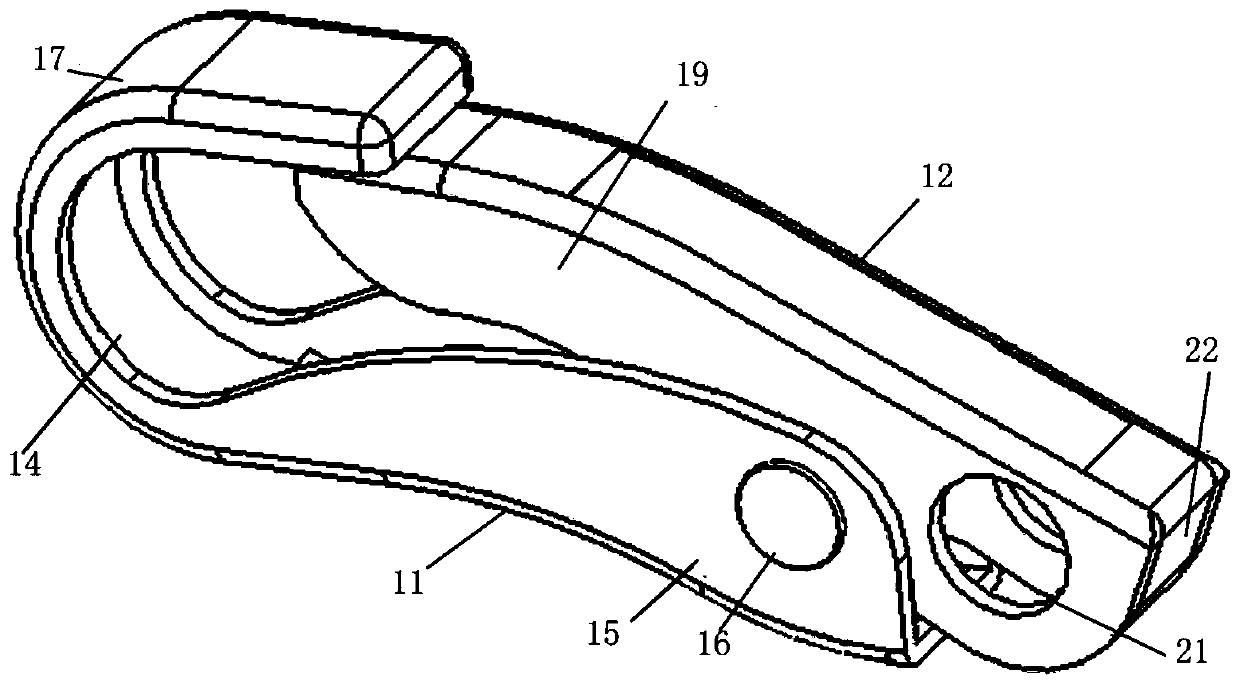

[0059]Please refer to the attached figure 1 , a kind of chain buckle of the present invention, comprises shell 11, is equipped with inner core 12 on shell 11, shell 11 and inner core 12 are hinged, shell 11 and inner core 12 are made of sheet material, shell 11 is crotch type, shell The head of 11 is provided with an elbow 17, the two sides of the casing 11 are provided with inwardly erected baffles 15, the tail of the baffle 15 is provided with a pin hole for accommodating the rivet 16, and the inside of the casing 11 is provided with a first groove 14, Both sides of the first groove 14 of the casing 11 are provided with baffles 15, the first groove 14 is formed between the inner side of the casing 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com