Ceramic filter tube denitration and desulfurization dust remover

A technology of desulfurization dust collector and dust collector, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of high equipment cost and large floor area, and reduce equipment investment and equipment floor space , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

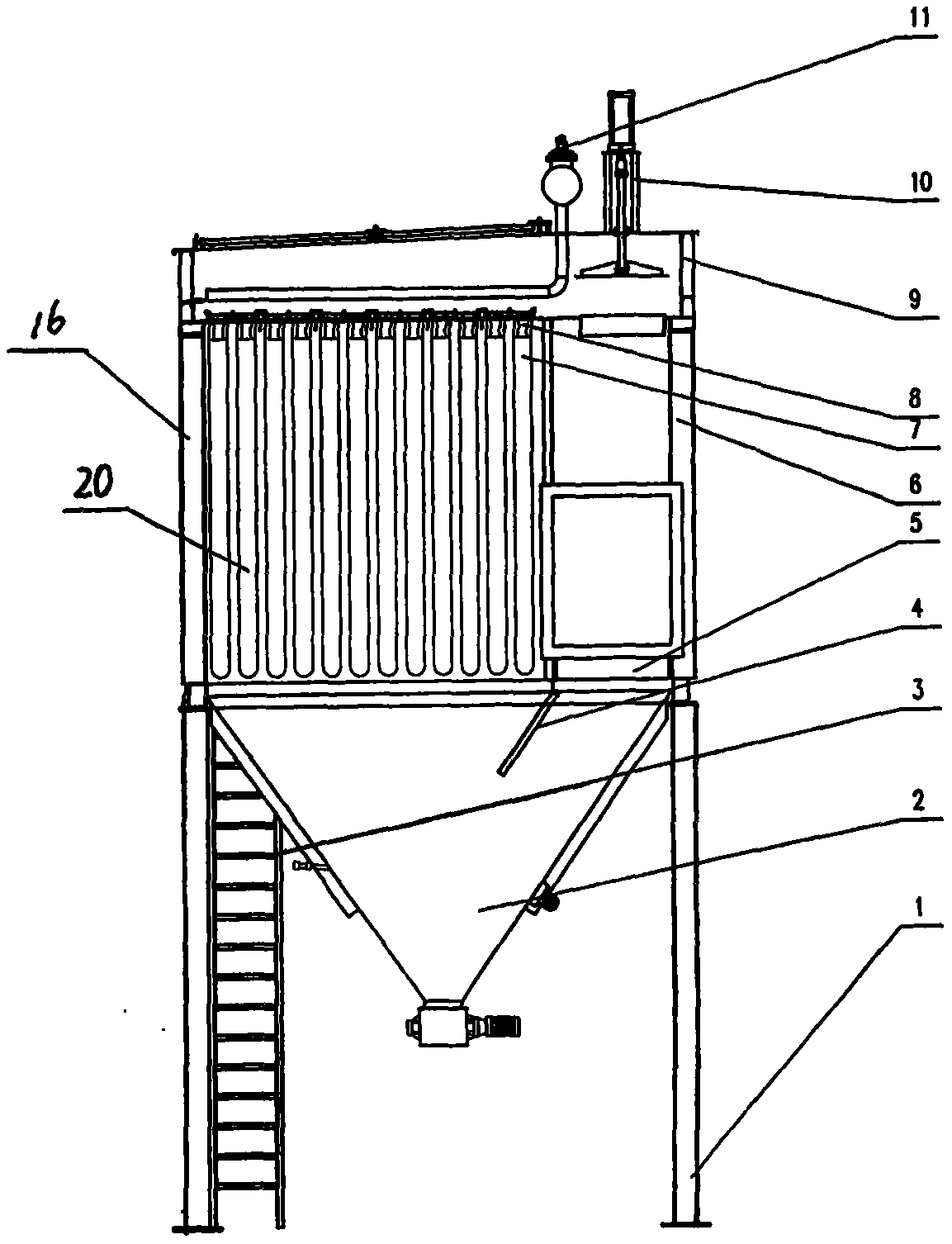

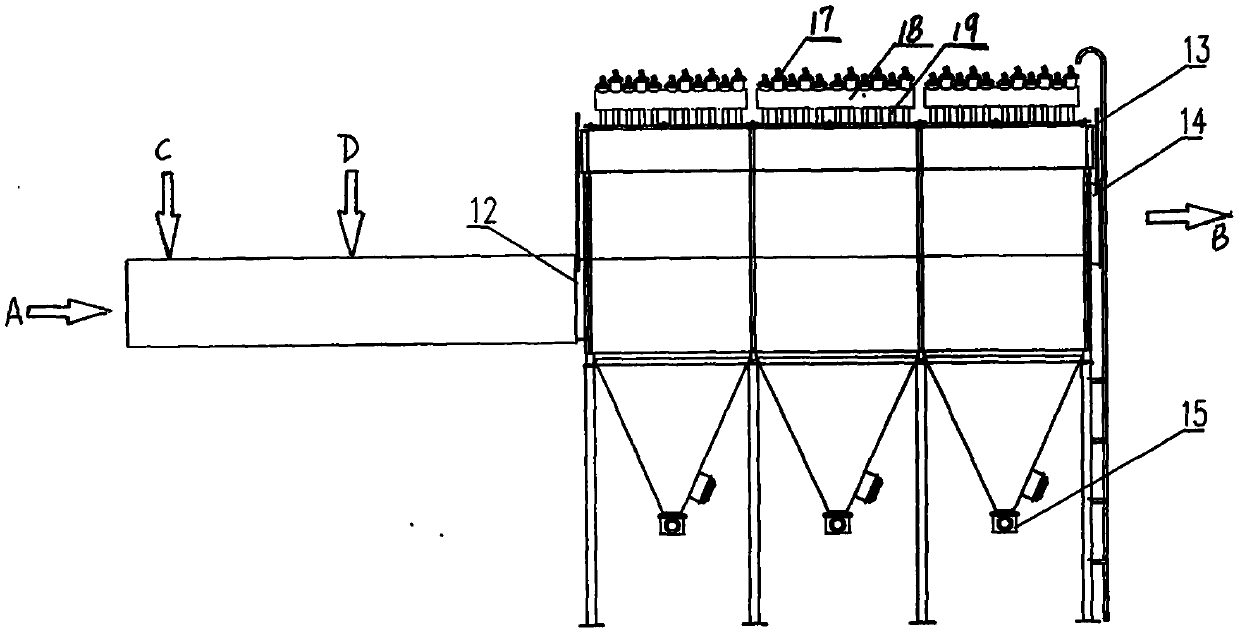

[0008] Such as figure 1 , figure 2 As shown, the ceramic filter tube 7 of a ceramic filter tube denitrification and desulfurization dust collector is arranged at the left inner end of the dust collector housing 16, the middle box body 6 is arranged at the right lower inner end of the dust collector housing 16, and the upper box body 9 is arranged at the lower right end of the dust collector housing 16. The upper inner end of the dust collector housing 16, the ash hopper 2 is set at the lower end of the dust collector housing 16, the star-shaped ash unloading valve 15 is connected to the lower mouth of the ash hopper 2 through a flange, and the mouth of the ceramic filter tube 7 is equipped with a venturi tube 8. The ceramic filter tube 7 and the Venturi tube 8 are fixed on the perforated plate inside the upper box body 9 through bolt connection with the pressure plate, the pulse cleaning device 11 and the off-line valve 10 are installed on the top of the upper box body 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com