Crushing and screening integrated machine suitable for heavy metal contaminated soil remediation

A polluted soil, crushing and screening technology, applied in the field of soil remediation, can solve the problems of deviation of leaching effect, decrease of leaching effect, and influence on the effect of soil remediation, etc., and achieve good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

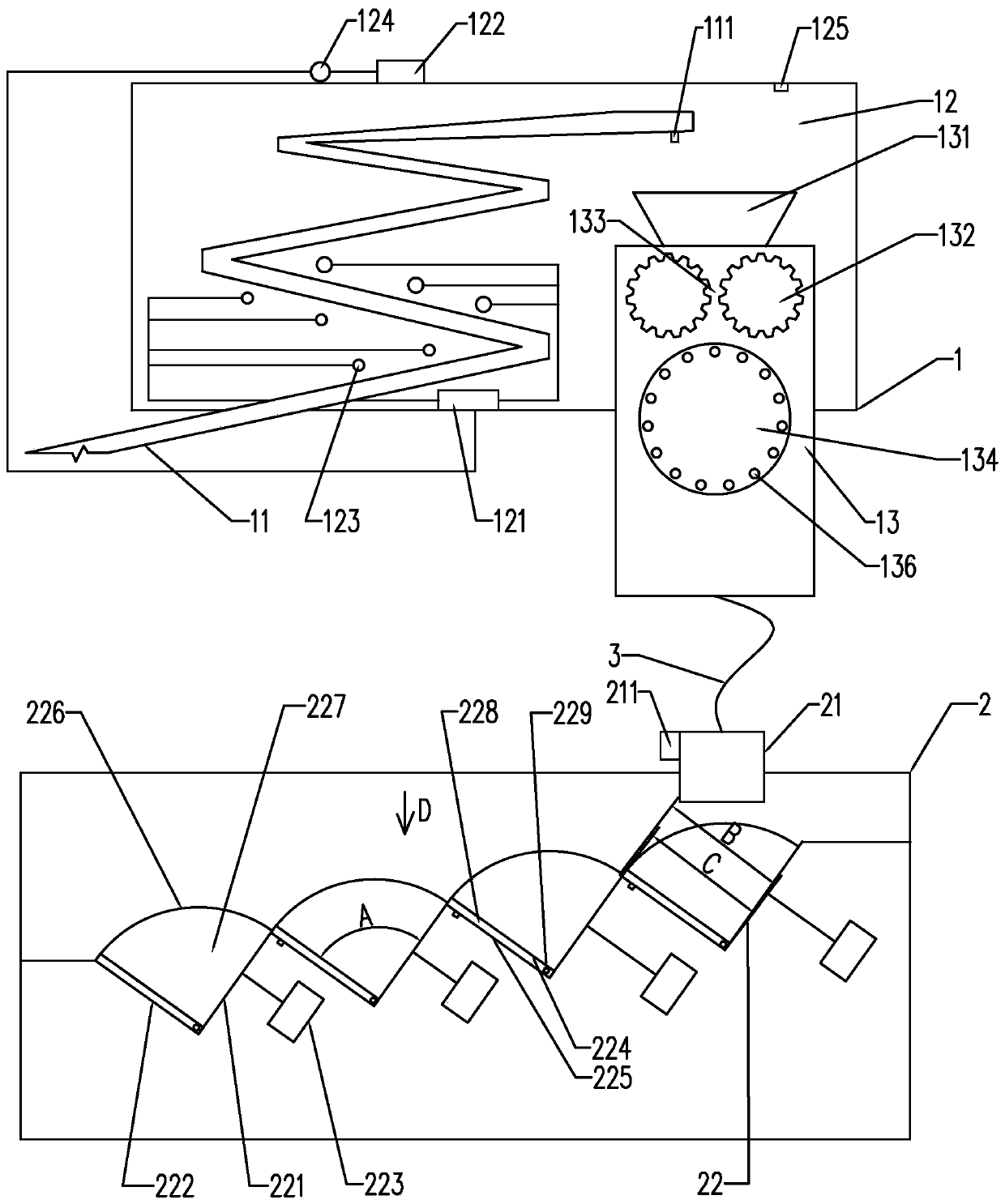

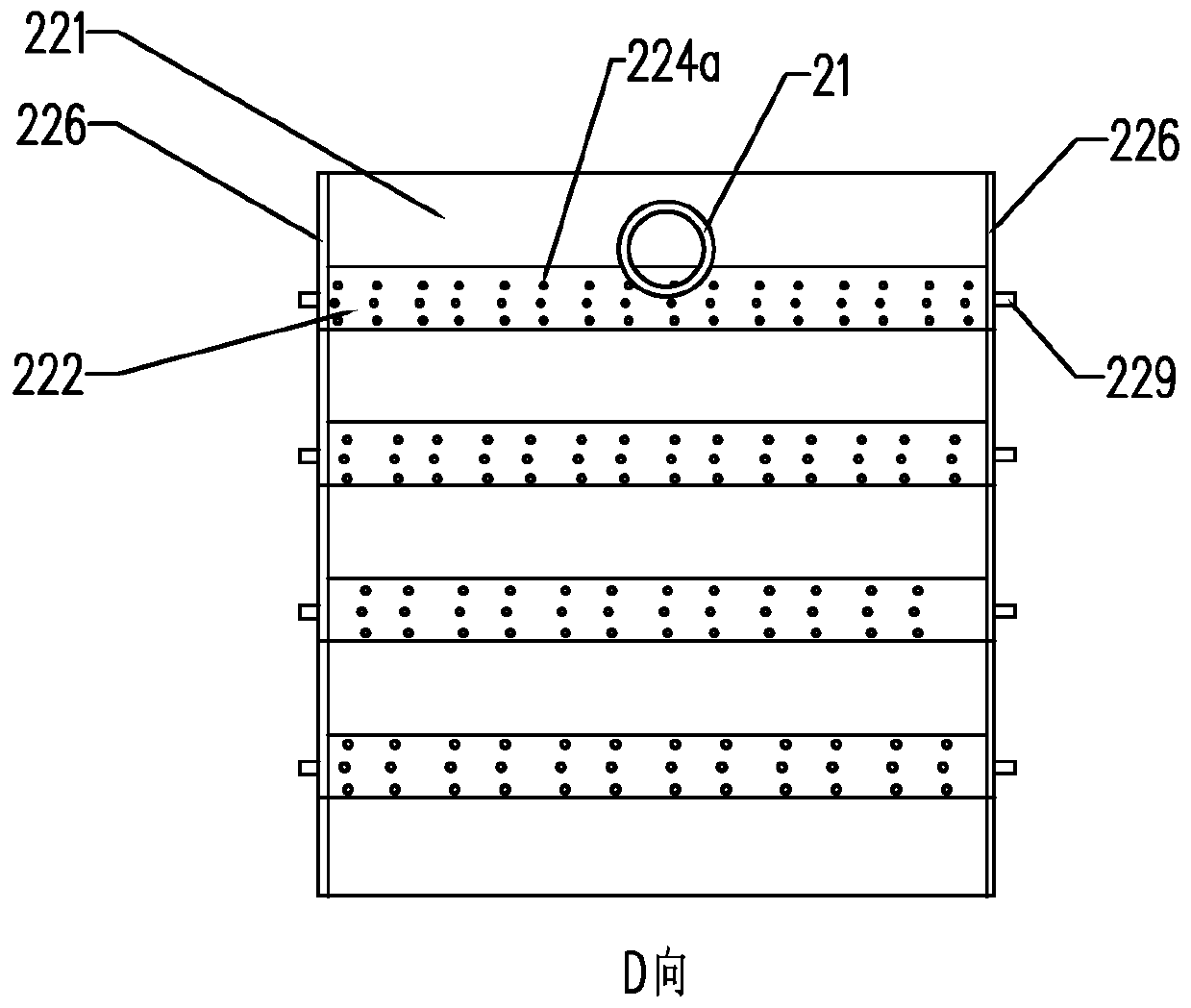

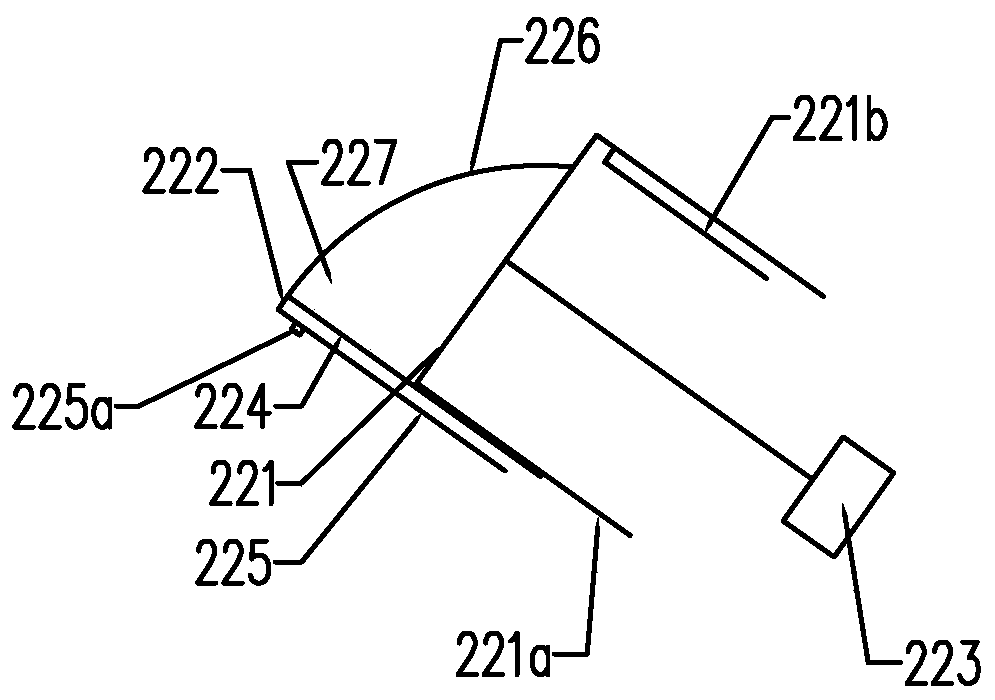

[0023] Such as Figure 1 to Figure 4 As shown, a crushing and screening integrated machine suitable for remediation of heavy metal-contaminated soil includes a crusher 1, a screening machine 2 and a connecting pipe 3;

[0024] Crusher 1 comprises conveyer belt 11, pretreatment chamber 12 and crushing chamber 13, conveyer belt 11 extends in the pretreatment chamber 12 from the outside and is used for inputting the soil block to be broken, is provided with heater 121 in the pretreatment chamber 12, from heater 121 extends a number of warm air nozzles 123, and the warm air nozzles 123 are aimed at the conveyor belt 11. The soil block is heated by the warm air during the transmission process of the conveyor belt 11, and the moisture is dried, and certain toxic substances are evaporated / decomposed, so that the agglomerated soil The block can be crushed better, the inlet 131 of the crushing chamber 13 extends into the pretreatment chamber 12, the end of the conveyor belt 11 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com