Improved crystallizer applicable to high-salinity wastewater quality grading crystallization

A high-salt wastewater, an improved technology, applied in crystallization separation, solution crystallization, separation methods, etc., can solve the problems such as material mixing and strengthening crystal particle size control, etc., to improve operating efficiency and fineness, flow field shearing The shear effect is enhanced and the effect of material mixing is strengthened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

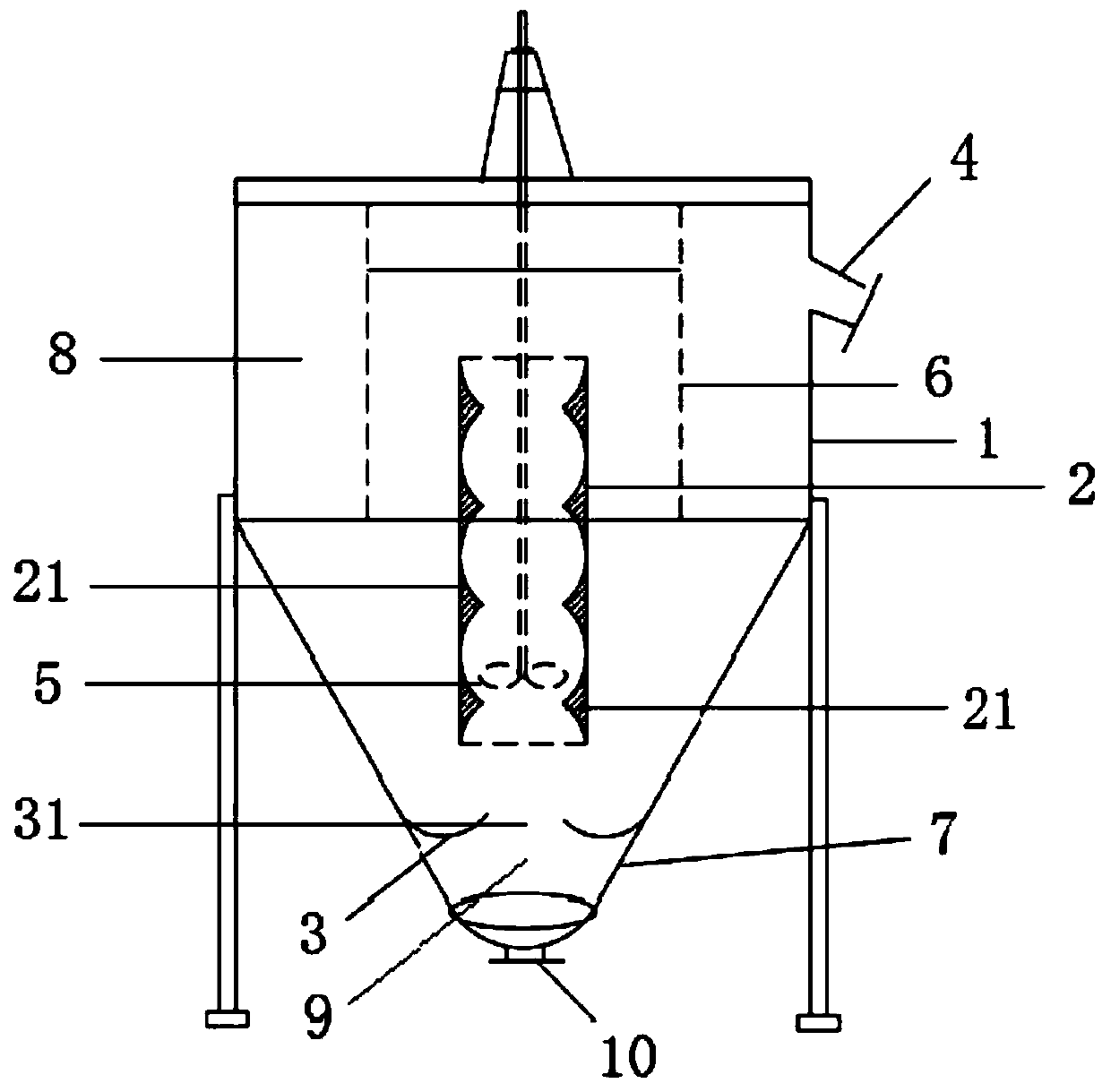

[0021] The improved crystallizer of embodiment 1 that is applicable to the fractional crystallization of high-salt wastewater, such as figure 1 As shown, including the outer cylinder 1 and the guide cylinder 2 and the guide baffle 3 arranged in the outer cylinder 1, the guide baffle 3 is arranged at the bottom of the outer cylinder 1, and the guide cylinder 2 and the guide baffle 3 both adopt arc Shaped design, the inner surface of the guide tube 2 is composed of a plurality of spherical arc surfaces 21 connected up and down in sequence. The flow guide baffle 3 is a downward convex annular flow guide baffle 3 , and the outer surface of the flow guide baffle 3 is tangent to the inner wall of the outer cylinder 1 .

Embodiment 2

[0022] The improved crystallizer of Example 2, which is suitable for the fractional crystallization of high-salt wastewater, is different from Example 1 in that in Example 2, the arc of the spherical arc corresponding to each spherical arc surface 21 is 0.7~2.4,

Embodiment 3

[0023] The difference between the improved crystallizer of Example 3 and Example 2, which is suitable for high-salt wastewater crystallization, is that in Example 3, the maximum inner diameter of the guide tube 2 is 0.15 to 0.45 times the inner diameter of the outer tube 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com