BCSLTM-SA composite microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and ceramics, applied in the field of microwave dielectric ceramics, can solve problems such as high sintering temperature, unstable structure, and performance deterioration, and achieve the effects of low sintering temperature, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method of the BCSLTM-SA composite microwave dielectric ceramic described in the above technical solution, comprising the following steps:

[0046] a) BaCO 3 , CaCO 3 、Sm 2 o 3 , La 2 o 3 、TiO 2 and MnO 2 After mixing, the first grinding treatment is carried out, and then the first pre-sintering is carried out to obtain BCSLTM pre-sintered material; at the same time, the Sm 2 o 3 and Al 2 o 3 After mixing, the second grinding treatment is carried out, and then the second pre-sintering is carried out to obtain the SA pre-sintered material;

[0047] b) After mixing the BCSLTM pre-sintered material obtained in step a) and the SA pre-sintered material, perform the third grinding treatment to obtain a powder; then add a binder to the powder for granulation and molding to obtain a ceramic raw material Blank; finally, the obtained ceramic green body is sintered to obtain BCSLTM-SA composite microwave dielectric cerami...

Embodiment 1

[0087] (1) According to Ba 1.2 Ca 0.4 SM 3 L a1.26 Ti 8.99 mn 0.01 o 26 The molar ratio weighs 34.3517g BaCO 3 , 5.808gCaCO 3 、75.8999g Sm 2 o 3 , 29.7767g La 2 o 3 , 104.1638g TiO 2 and 0.6411g MnO 2 , mixed to obtain the first mixture; the first mixture, zirconium balls and deionized water were wet-milled with a planetary mill for 6 hours at a mass ratio of 1:2:2, dried at 150°C, and dried at 850 Pre-fired at ℃ (in the air atmosphere) for 3 hours, the heating rate was 3 ℃ / min, and cooled with the furnace to obtain BCSLTM pre-fired material.

[0088] (2) According to SmAlO 3 The molar ratio weighs 193.4339g Sm 2 o 3 and 56.5661g Al 2 o 3 , mixed to obtain the second mixture; the second mixture, zirconium balls and deionized water were wet-milled with a planetary mill for 6 hours at a mass ratio of 1:2:2, dried at 150°C, and dried at 1100 Pre-fired at ℃ (in the air atmosphere) for 2 hours, the heating rate was 3 ℃ / min, and cooled with the furnace to obtain S...

Embodiment 2

[0096] (1) According to Ba 1.2 Ca 0.4 SM 3 L a1.26 Ti 8.99 mn 0.01 o 26 The molar ratio weighs 34.3517g BaCO 3 , 5.808gCaCO 3 、75.8999g Sm 2 o 3 , 29.7767g La 2 o 3 , 104.1638g TiO 2 and 0.6411g MnO 2 , mixed to obtain the first mixture; the first mixture, zirconium balls and deionized water were wet-milled with a planetary mill for 6 hours at a mass ratio of 1:2:2, dried at 150°C, and dried at 850 Pre-fired at ℃ (in the air atmosphere) for 3 hours, the heating rate was 3 ℃ / min, and cooled with the furnace to obtain BCSLTM pre-fired material.

[0097] (2) According to SmAlO 3 The molar ratio weighs 193.4339g Sm 2 o 3 and 56.5661g Al 2 o 3 , mixed to obtain the second mixture; the second mixture, zirconium balls and deionized water were wet-milled with a planetary mill for 6 hours at a mass ratio of 1:2:2, dried at 150°C, and dried at 1100 Pre-fired at ℃ (in the air atmosphere) for 2 hours, the heating rate was 3 ℃ / min, and cooled with the furnace to obtain S...

PUM

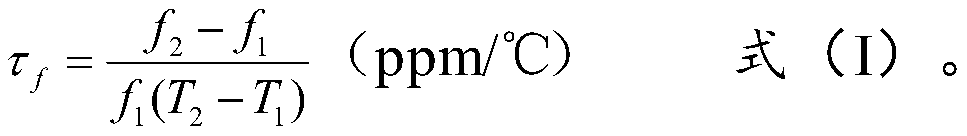

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com