A kind of preparation method of azobenzene-graphene energy storage material containing hyperbranched structure

A technology of energy storage materials and branched structures, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of short half-life, low energy density, limiting the application of azobenzene molecules, etc., and achieve long half-life and high storage The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

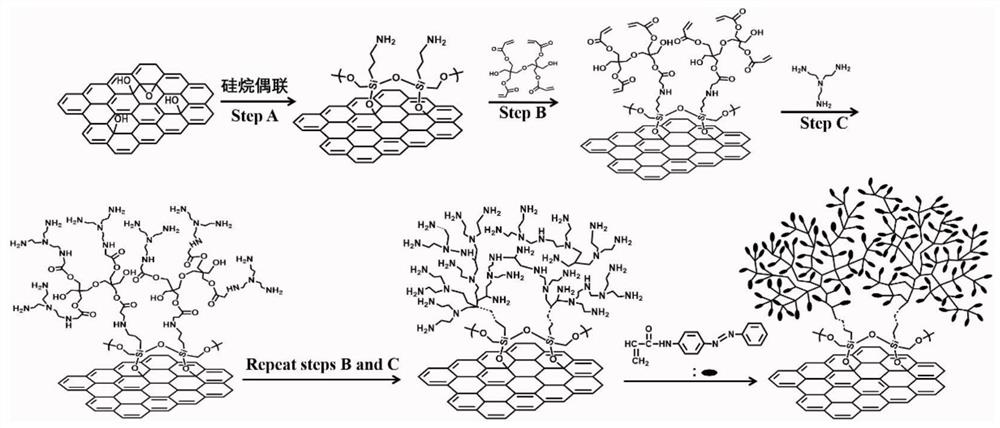

[0027] 1) Ultrasonic dispersion of 50mg graphene in a mixed solution of 50ml absolute ethanol and 10ml deionized water, add 10ml 3-aminopropyltriethoxysilane dropwise, then stir the reaction in an oil bath at 60°C, condense and reflux 8h. Finally, the unreacted coupling agent in the product was filtered and washed four times with deionized water and absolute ethanol, respectively, and vacuum-dried at 40° C. for 12 hours to obtain a dry product. Disperse 40 mg of the product in 50 ml of ethanol solution, add 10 ml of poly-dipentaerythritol tetraacrylate, stir at room temperature for 3 h by Michael addition reaction, and wash with absolute ethanol for 4 times to remove unreacted poly-dipentaerythritol tetraacrylate , and obtained hyperbranched graphene hybrids containing carbon-carbon double bonds after vacuum drying. Finally, 50 mg of the graphene hybrid was dispersed in 50 ml of absolute ethanol, then 10 ml of tris(2-aminoethyl)amine was added, stirred at room temperature for...

Embodiment 2

[0031]1) Ultrasonic dispersion of 50mg graphene in a mixed solution of 50ml absolute ethanol and 10ml deionized water, add 15ml 3-aminopropyltriethoxysilane dropwise, then stir the reaction in an oil bath at 60°C, condense and reflux 10h. Finally, the unreacted coupling agent in the product was filtered and washed four times with deionized water and absolute ethanol respectively, and vacuum-dried at 50° C. for 12 hours to obtain a dry product. Disperse 40 mg of the product in 50 ml of ethanol solution, add 15 ml of poly-dipentaerythritol tetraacrylate, stir at room temperature for 3 h by Michael addition reaction, and wash with absolute ethanol for 4 times to remove unreacted poly-dipentaerythritol tetraacrylate , and obtained hyperbranched graphene hybrids containing carbon-carbon double bonds after vacuum drying. Finally, 50 mg of the graphene hybrid was dispersed in 50 ml of absolute ethanol, then 15 ml of tris(2-aminoethyl)amine was added, stirred at room temperature for ...

Embodiment 3

[0035] 1) Ultrasonic dispersion of 50 mg of graphene in a mixed solution of 50 ml of absolute ethanol and 10 ml of deionized water, adding 20 ml of 3-aminopropyltriethoxysilane dropwise, then stirring the reaction in an oil bath at 60 ° C, condensing and refluxing 12h. Finally, the unreacted coupling agent in the product was filtered and washed six times with deionized water and absolute ethanol, respectively, and vacuum-dried at 50° C. for 24 hours to obtain a dry product. Disperse 40 mg of the product in 50 ml of ethanol solution, add 20 ml of poly-dipentaerythritol tetraacrylate, stir at room temperature for 5 h by Michael addition reaction, and wash with dehydrated alcohol for 6 times to remove unreacted poly-dipentaerythritol tetraacrylate , and obtained hyperbranched graphene hybrids containing carbon-carbon double bonds after vacuum drying. Finally, 50 mg of the graphene hybrid was dispersed in 50 ml of absolute ethanol, then 20 ml of tris(2-aminoethyl)amine was added,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com