Mechanical full-bridge type circulating liquid gas compressing part and energy storage system

A liquid-gas compression and full-bridge technology, which is applied in the direction of mechanical equipment, liquid variable-capacity machinery, variable-capacity engines, etc., can solve the problems of bulky, difficult methods, and difficult to control, etc., to achieve small size and environment-friendly Pollution, development-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

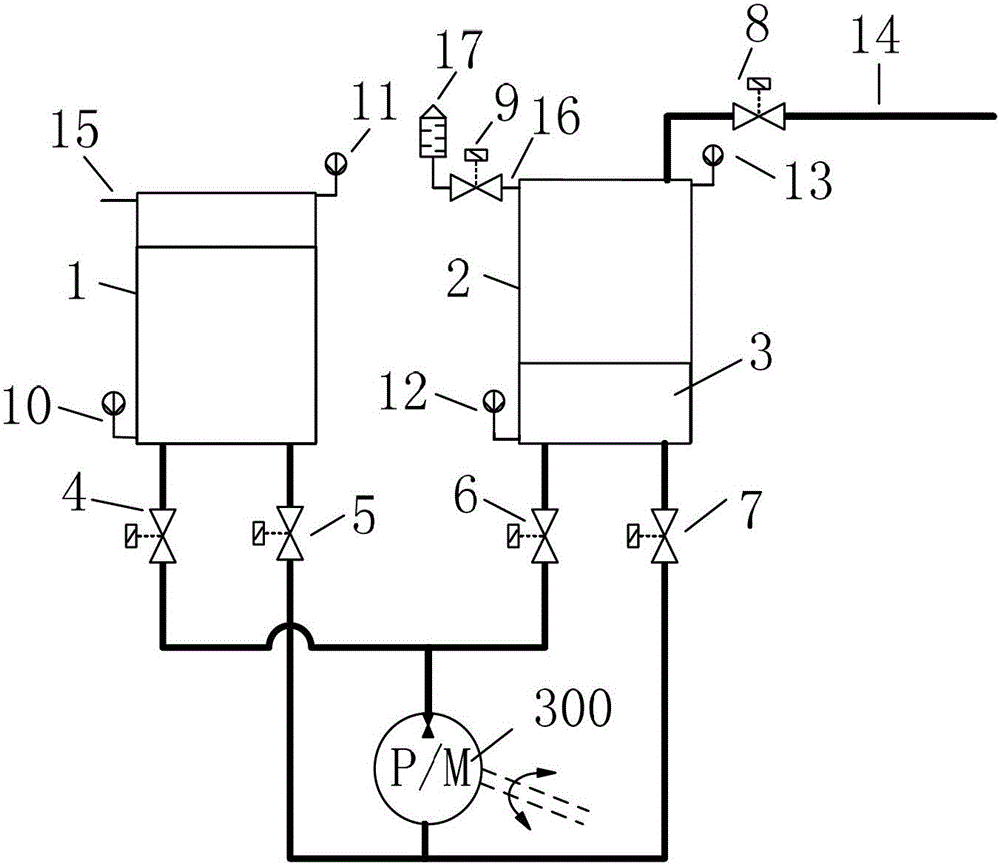

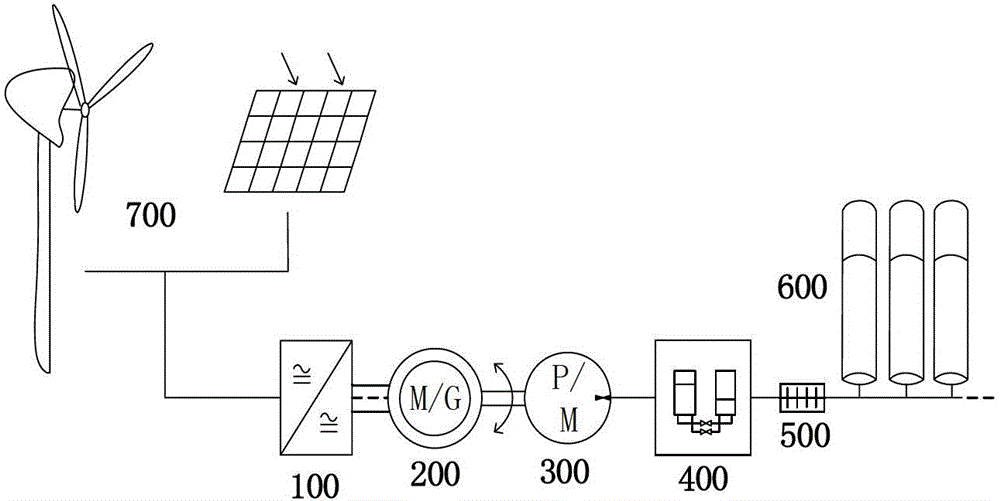

[0021] refer to Figure 1 to Figure 2 Examples of the present invention will be described.

[0022] In order to make the above objects, features and advantages more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The mechanical full-bridge circulating liquid-gas compressed air energy storage system of the present invention, such as figure 2 As shown, it includes an energy source 700, a converter 100, a motor / generator 200, a hydraulic pump / motor 300, a circulating liquid-gas compression component 400, a heat exchanger 500, and a high-pressure vessel 600, which are connected in series; the circulating liquid-gas Compression parts such as figure 1 As shown, it includes a normal pressure liquid storage tank 1, a high pressure liquid storage tank 2, a liquid 3, a first valve 4, a second valve 5, a third valve 6, a fourth valve 7, a fifth valve 8, a sixth valve 9, Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com