A process for producing purified phycoerythrin

A technology for purifying phycoerythrin and process, which is applied in the field of producing purified phycoerythrin, can solve the problems of large difference in influence, no uniformity, and cannot be copied by other algae, etc., and achieves the effects of high biological activity, promotion of accumulation, and improvement of photosynthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A process for producing purified phycoerythrin, comprising the steps of:

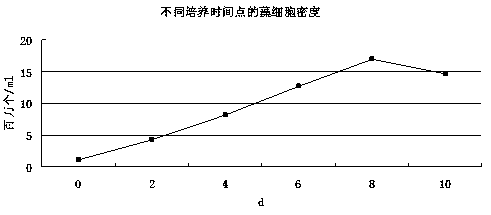

[0029] Inoculate the Porphyridium algae cultivated to the logarithmic growth phase into the seed tank containing the f / 2 medium, and the inoculation initial density is 2×10 5 cells / ml, light intensity 4000lux, culture at 23°C, light-to-dark ratio of 14:10, air flow rate of 0.4vvm, culture for 2 days, and collect Porphyridium algae seed liquid;

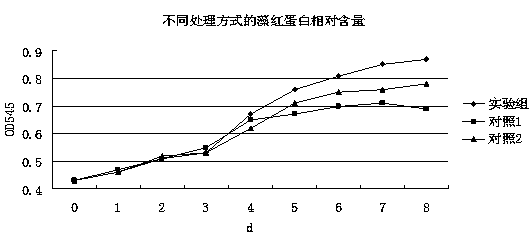

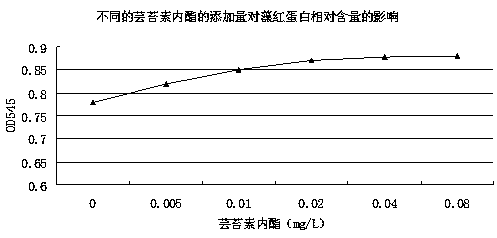

[0030] Put the Porphyridium algae seed solution into the reaction tank containing artificially synthesized culture solution according to the inoculation amount of 10%, control the light intensity to 5000Lux, the air flow rate to 0.5vvm, cultivate at 25°C, and the light-to-dark ratio is 14:10 , cultivated for 3 days, then added 0.02 mg / L of brassinolide and 0.3 g / L of bionitrogen, and continued to cultivate for 5 days to obtain algae liquid;

[0031] The components of the culture solution are: sodium chloride 12g / L, sodium nitrate 1g / L, sodium carbonate 0...

Embodiment 2

[0034] A process for producing purified phycoerythrin, comprising the steps of:

[0035] Inoculate the Porphyridium algae cultivated to the logarithmic growth phase into the seed tank containing the f / 2 medium, and the inoculation initial density is 2×10 5 cells / ml, light intensity 4000lux, culture at 23°C, light-to-dark ratio of 14:10, air flow rate of 0.4vvm, culture for 2 days, and collect Porphyridium algae seed liquid;

[0036]Put the Porphyridium algae seed liquid into the reaction tank containing artificially synthesized culture liquid according to the inoculum amount of 10%, control the light intensity to 6000Lux, the air flow rate to 0.3vvm, cultivate at 22°C, and the light-to-dark ratio is 14:10 , cultivated for 3 days, then added 0.01 mg / L of brassinolide and 0.4 g / L of biological nitrogen, and continued to cultivate for 4 days to obtain algae liquid;

[0037] The components of the culture solution are: sodium chloride 12g / L, sodium nitrate 1g / L, sodium carbonate 0...

Embodiment 3

[0040] A process for producing purified phycoerythrin, comprising the steps of:

[0041] Inoculate the Porphyridium algae cultivated to the logarithmic growth phase into the seed tank containing the f / 2 medium, and the inoculation initial density is 2×10 5 cells / ml, light intensity 4000lux, culture at 23°C, light-to-dark ratio of 14:10, air flow rate of 0.4vvm, culture for 2 days, and collect Porphyridium algae seed liquid;

[0042] Put the Porphyridium algae seed solution into the reaction tank containing artificially synthesized culture solution according to the inoculum amount of 10%, control the light intensity to 6000Lux, the air flow rate to 0.5vvm, cultivate at 24°C, and the light-to-dark ratio is 14:10 , cultivated for 3d, then added 0.04mg / L brassinolide and 0.34g / L bionitrogen, and continued to cultivate for 5d, to obtain algae liquid;

[0043] The components of the culture solution are: sodium chloride 12g / L, sodium nitrate 1g / L, sodium carbonate 0.5g / L, borax 0.2g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com