Subgrade structure and construction method thereof

A technology of roadbed and road bed, which is applied in infrastructure engineering, roads, roads, etc., can solve problems such as road surface deformation, water damage aggravation, vertical structure impermeability, etc., and achieve the effect of reducing damage and delaying road surface aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

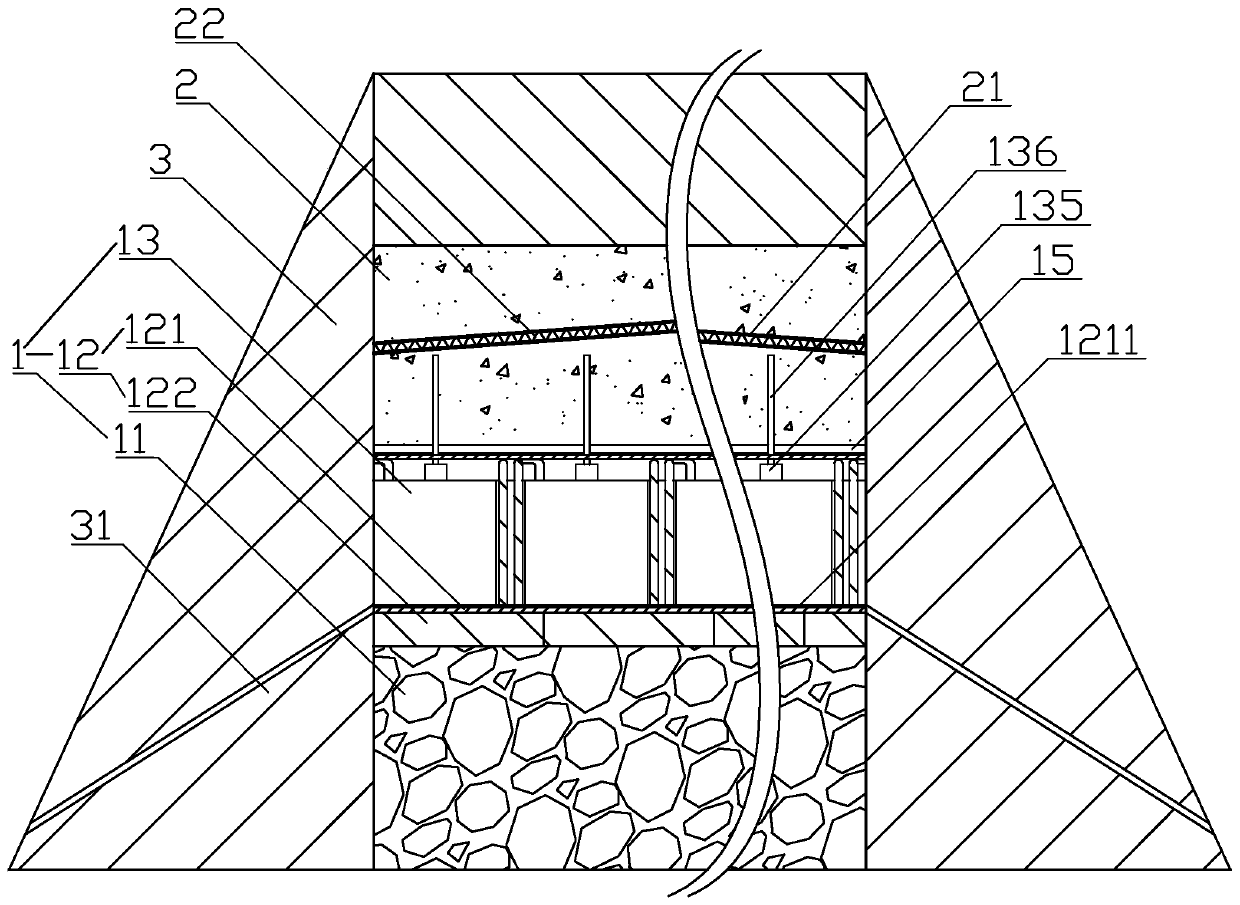

[0043] Embodiment 1: as figure 1 As shown, a subgrade structure includes a lower road bed 1 and an upper road bed 2 arranged sequentially from bottom to top, the upper road bed 2 is a road surface structure, and side slopes 3 are arranged on both sides of the road bed.

[0044] like figure 1 As shown, the lower road bed 1 includes a base layer 11 , a waterproof layer 12 and a water storage layer 13 arranged in sequence from bottom to top. The base 11 is filled with sand and gravel with a particle size of 2-4 cm. The sand and gravel have less capillary water, are not easy to be frozen, are convenient to obtain materials, and have good water stability. The base 11 built in this way is not easy to subside.

[0045] The waterproof layer 12 includes a waterproof coiled material 121 and load-bearing bricks 122. In this embodiment, the load-bearing bricks 122 are solid bricks made of clay, and the load-bearing bricks 122 are neatly laid on the upper surface of the base layer 11 afte...

Embodiment 2

[0051] Example 2: Combining Figure 1-Figure 3 , a construction method for a subgrade structure, comprising the following steps:

[0052] Step S1: survey and map the terrain, calculate the total length of the road, remove the original surface debris, and divide the construction area;

[0053] Step S2: Excavate the earthwork and stonework of the subgrade, and use lime to spread out the sideline of the subgrade, the center line of the line and the sideline of the filling, and mark the height of loose paving so as to control the construction thickness;

[0054] Step S3: pouring the side slope 3 and opening a dark ditch 31, then pouring the base 11 and leveling;

[0055] Step S4: laying load-bearing bricks 122 and waterproof coiled material 121 to form waterproof layer 12;

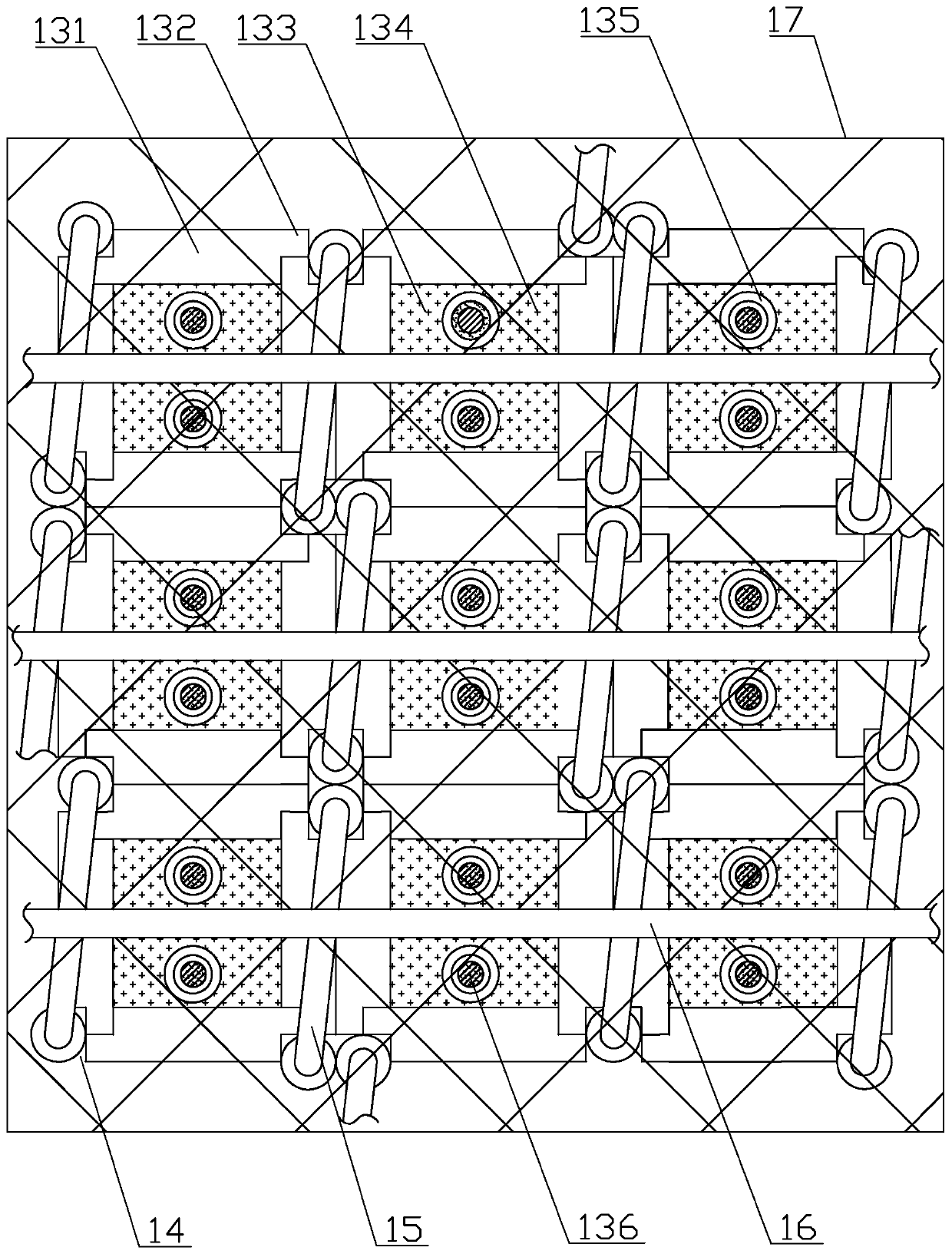

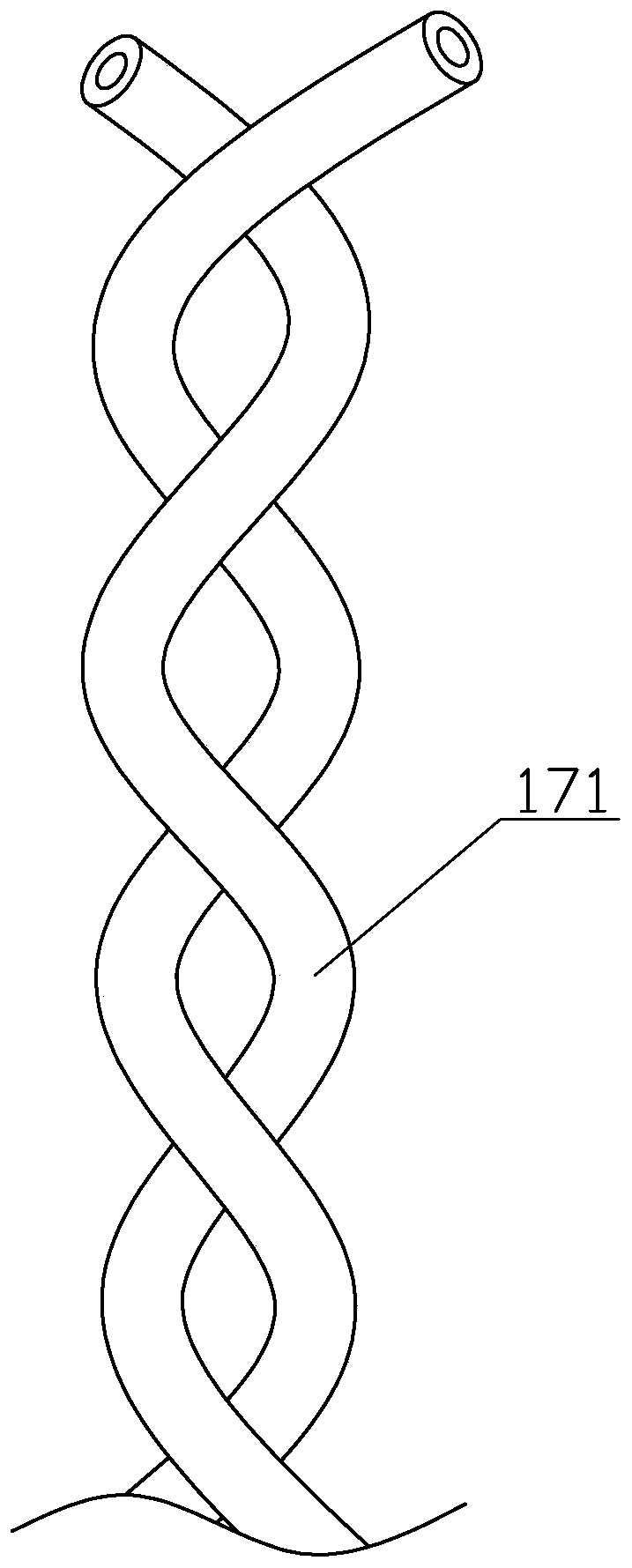

[0056] Step S5: Stack the cut square bricks 131, arrange the stressed steel bars 15, bamboo tubes 135 and vertical steel bars 136, then fill the bamboo tubes 135 with basalt gravel with a particle size of 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com