Anti-aging polypeptide composition and application thereof

A polypeptide composition and anti-aging technology, which can be applied in cosmetic preparations, cosmetics, cosmetic preparations, etc., can solve the problem of lack of elastin signal protein, etc., achieve excellent skin feeling, increase the content of moisturizing factors, and the formula is safe and reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Anti-aging polypeptide freeze-dried powder, the formula is shown in Table 1.

[0052] Table 1

[0053]

[0054] Preparation process: Stir and dissolve the material of component A in Table 1 evenly, then mix with the material of group B, and filter with a Sack filter (filter membrane pore size: 0.22 μm). After the filling machine is adjusted, it will be sub-packed and plugged; use a freeze dryer to freeze-dry, put it into the box, start it at -45°C and pre-freeze for 4 hours, sublimate for about 10 hours for the first time, and sublime for about 9 hours for the second time, and stop at 25-28°C Unpack the box, vacuum plug, take out the box, and tie the cover to obtain the anti-aging polypeptide freeze-dried powder.

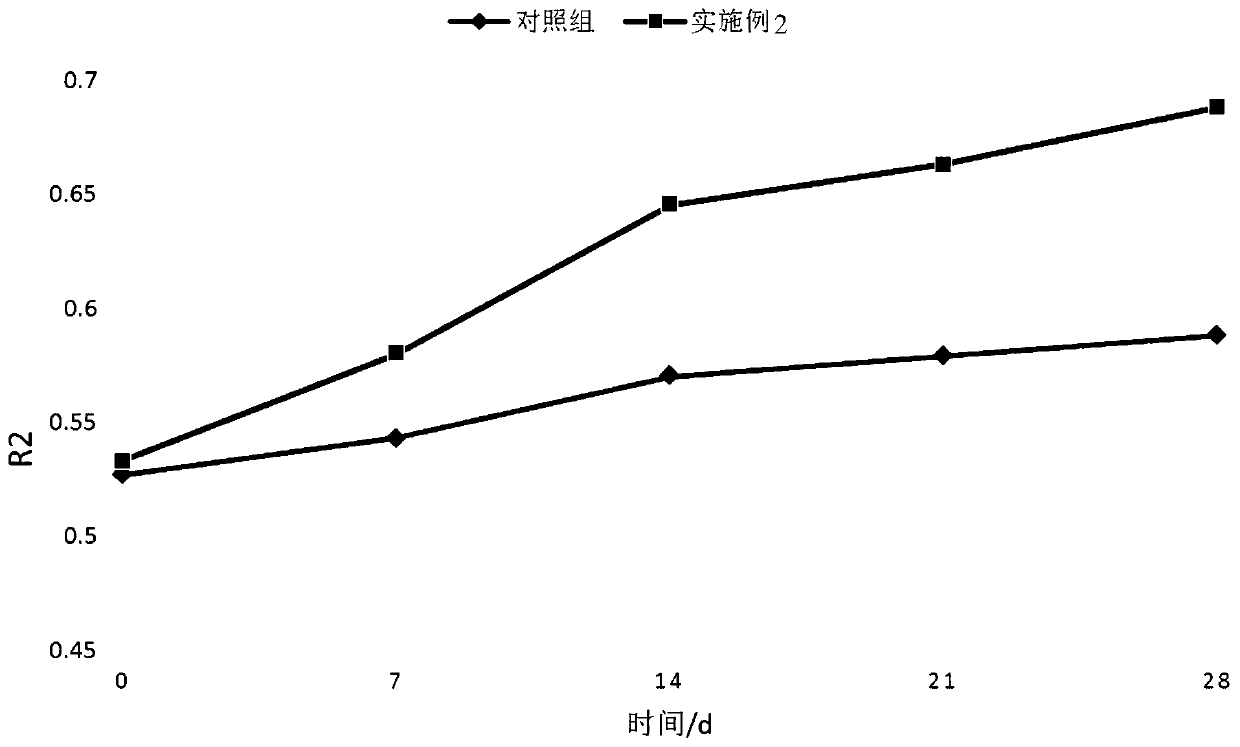

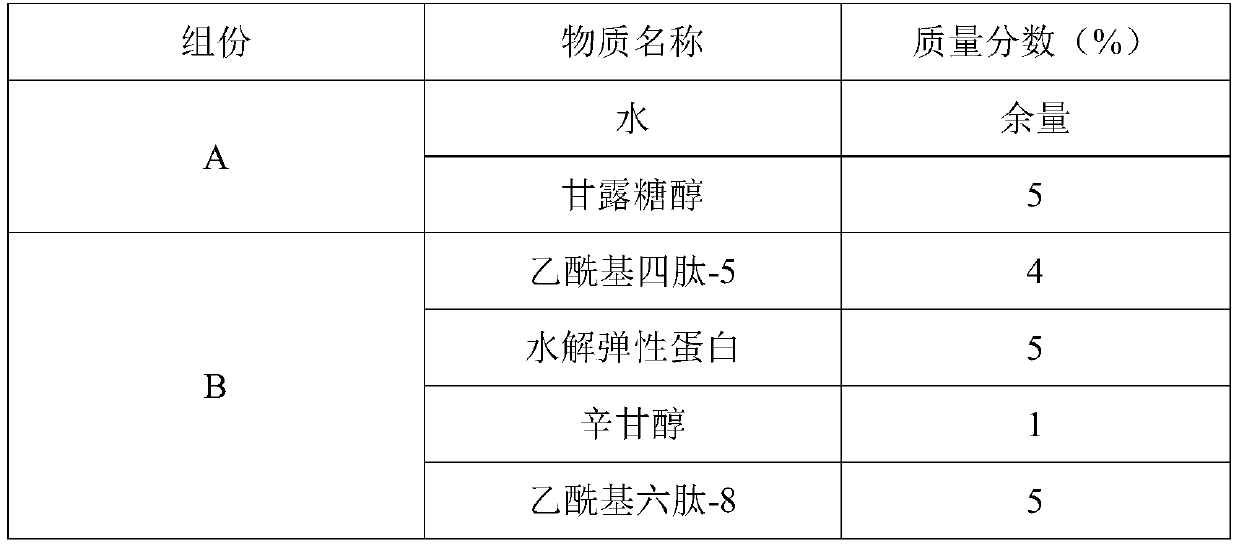

Embodiment 2

[0056] Anti-aging polypeptide essence, the formula is shown in Table 2.

[0057] Table 2

[0058]

[0059] Preparation process: According to the formula in Table 2, add component A into the emulsification pot, heat to 85°C, keep warm and stir for 20 minutes, homogenize for 5 minutes, stir and cool down to 45°C, then add component B in turn, stir and cool to 38°C ℃, after passing the quality inspection, the material is filtered out to obtain the anti-aging polypeptide essence.

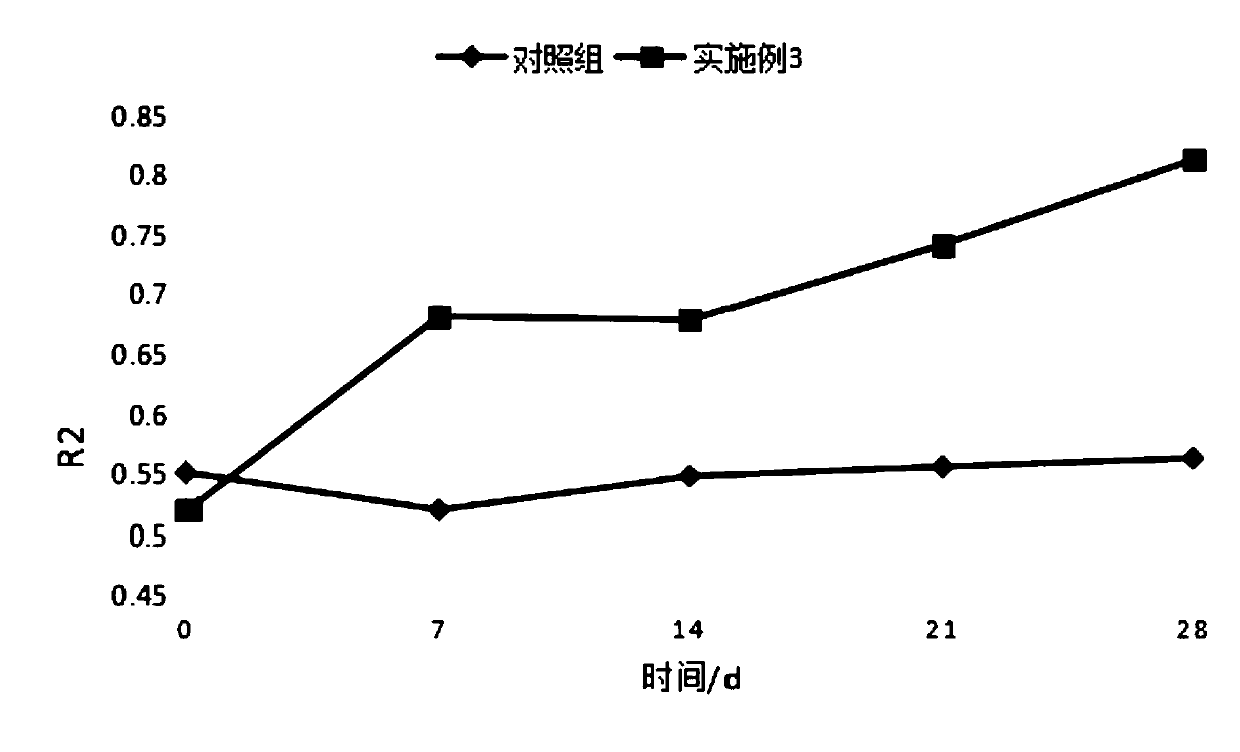

Embodiment 3

[0061] Anti-aging polypeptide emulsion, the formula is shown in Table 3.

[0062] table 3

[0063]

[0064]

[0065] Preparation process: According to the formula in Table 3, add component A into the emulsification pot, heat to 85°C, and keep stirring for 20 minutes. Add component B into the oil phase pot, heat to 85°C, and keep stirring for 10 minutes. Then slowly pump component B into the emulsification pot, homogenize for 5 minutes, add component C when the temperature is lowered to 70°C with stirring and homogenize for 2 minutes. Slowly stir evenly, cool down to 45°C, then add component D in turn, stir and cool to 38°C, pass the quality inspection and filter out to obtain anti-aging emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com