Preparing method and application of NiPS3 nanosheets of self-supporting structure

A self-supporting structure, nanosheet technology, applied in chemical instruments and methods, electrodes, electrolysis processes, etc., can solve the problems of unsatisfactory HER performance, high synthesis temperature and time, and complicated preparation process, and achieve low cost, synthetic The effect of low temperature and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

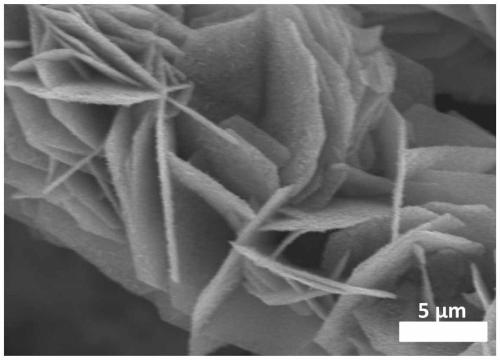

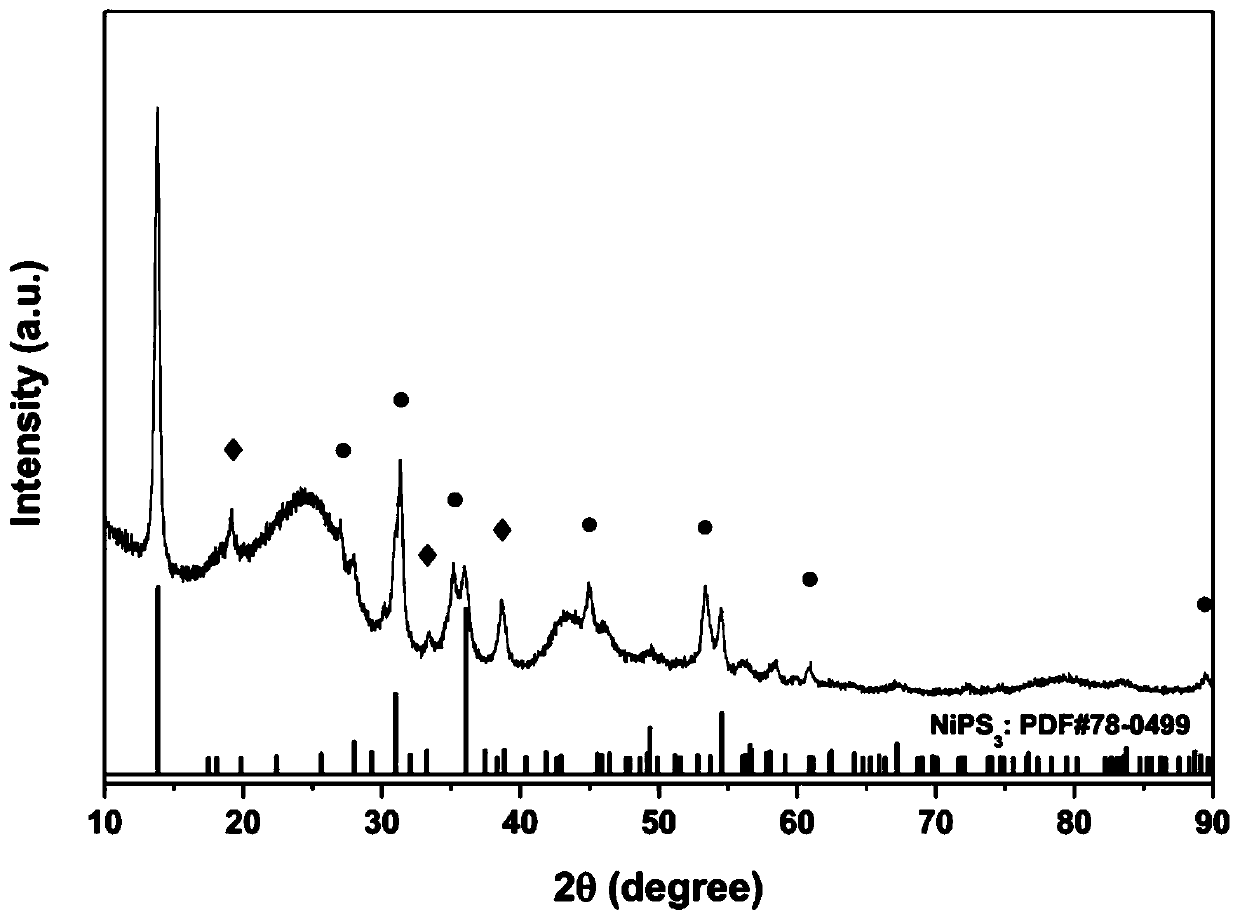

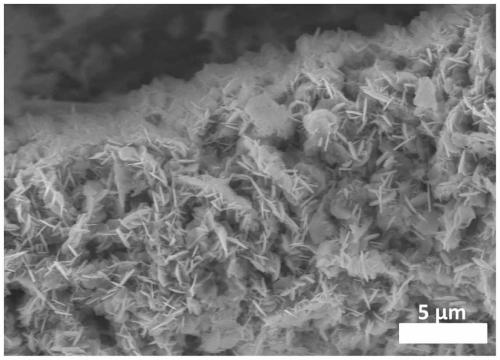

[0032] Specific implementation mode 1: NiPS with self-supporting structure in this implementation mode 3 The preparation method of nanosheet is realized according to the following steps:

[0033] 1. Ultrasonic cleaning of the carbon cloth to obtain the cleaned carbon cloth;

[0034] Two, according to stoichiometric ratio P:S=1:3 ratio red phosphorus powder and sublimation sulfur powder are mixed, obtain phosphorus sulfur powder mixture after grinding;

[0035] 3. Add nickel salt, urea and ammonium fluoride into ultrapure water and stir to dissolve to obtain a reaction solution;

[0036] 4. Immerse the cleaned carbon cloth into the reaction solution in step 3, and conduct a hydrothermal reaction at 100-160°C for 6-10 hours. After the reaction, take out the carbon cloth, wash and dry it to obtain the precursor;

[0037] 5. Pour the mixture of phosphorus and sulfur powder into the open reactor, put the open reactor and the precursor into the corundum boat together, cover the co...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 1, the carbon cloth is ultrasonically cleaned with acetone, ethanol, and ultrapure water for 15-25 minutes respectively.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the carbon cloth in step 1 is a hydrophilic hard carbon cloth.

[0041] In this embodiment, when the conductive carbon cloth is a hydrophobic carbon cloth, it needs to be hydrothermally treated with concentrated nitric acid at 120° C. for 4 hours to make it hydrophilic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com