Fabric and preparation method thereof

A fabric and cloth technology, applied in the field of fabric and its preparation, can solve the problems of poor environmental protection, powder drop of aerogel materials, poor compatibility between oily coating and fabric, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

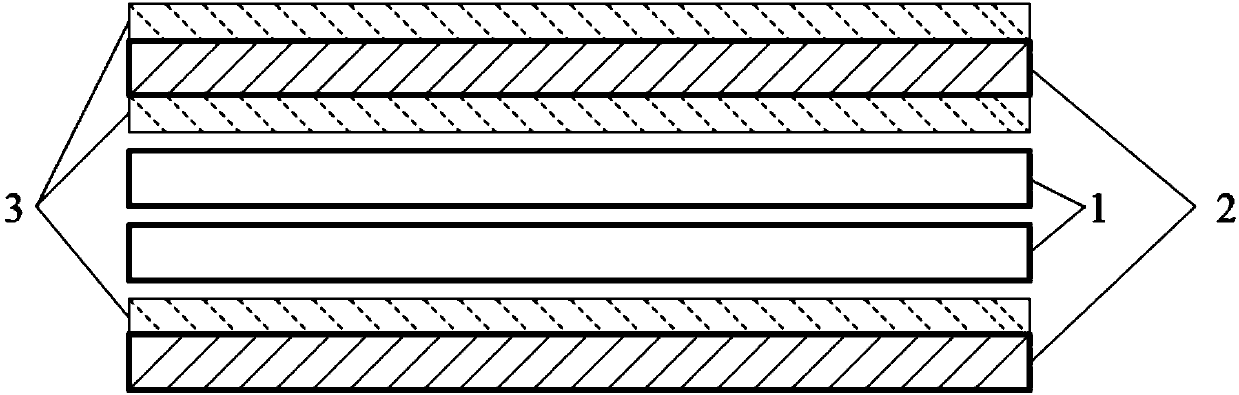

[0023] The preparation method of fabric provided by the invention comprises the following steps:

[0024] The thermal radiation shielding material is coated on the surface of the cloth and cured to obtain the coated cloth. In this step, the thermal radiation shielding material can be coated on the surface of the cloth by one or more combinations of brushing, spraying or dipping, wherein the coating is carried out on one side of a piece of cloth, and the Coating is performed on both sides of another piece of fabric, and then cured at 90° C. to 150° C. for 25 minutes to 45 minutes to obtain a coated fabric. In this step, the heat radiation shielding material is a water-based paint, and the heat radiation shielding material is a water-based low-infrared emissivity paint, wherein the emissivity of the paint is 0.2 to 0.6, and the cloth is one or more of polyester, polyester cotton, and nylon. Various combinations. In this step, the use of water-based low-infrared emissivity coat...

Embodiment 1

[0028] A water-based low-infrared emissivity paint with an infrared emissivity of 0.2 is applied to the nylon cloth by brushing, wherein one side of a piece of cloth is coated, and the other side of the cloth is coated on both sides, and then, Curing at 90°C for 45 minutes to obtain a coated fabric. The fabric coated on one side is used as the inner layer of the fabric, and the fabric coated on both sides is used as the outer layer of the fabric. The polyethylene material (XPE) is used as the middle layer, wherein the coated side of the single-side coated fabric is in direct contact with the chemically cross-linked polyethylene material (XPE), and finally composited by sewing to obtain a fabric.

Embodiment 2

[0030] A water-based low-infrared emissivity paint with an infrared emissivity of 0.6 is applied to the nylon cloth by brushing, wherein one side of a piece of cloth is coated, and the other side of the cloth is coated on both sides, and then, Curing at 150°C for 25 minutes to obtain a coated fabric. The fabric coated on one side is used as the inner layer of the fabric, and the fabric coated on both sides is used as the outer layer of the fabric. At the same time, two layers of 2mm-thick The chemically cross-linked polyethylene material (XPE) is used as the middle layer, wherein the coated side of the single-sided coated fabric is in direct contact with the chemically cross-linked polyethylene material (XPE), and finally compounded by sewing to make get the fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com