Preparation method of acetone dimethyl alcohol

A technology of acetone dimethyl acetal and methanol, which is applied in the field of organic compound preparation, can solve the problems of high reaction yield, high catalyst activity, and low energy consumption, and achieve the effects of simple operation, increased reaction yield, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

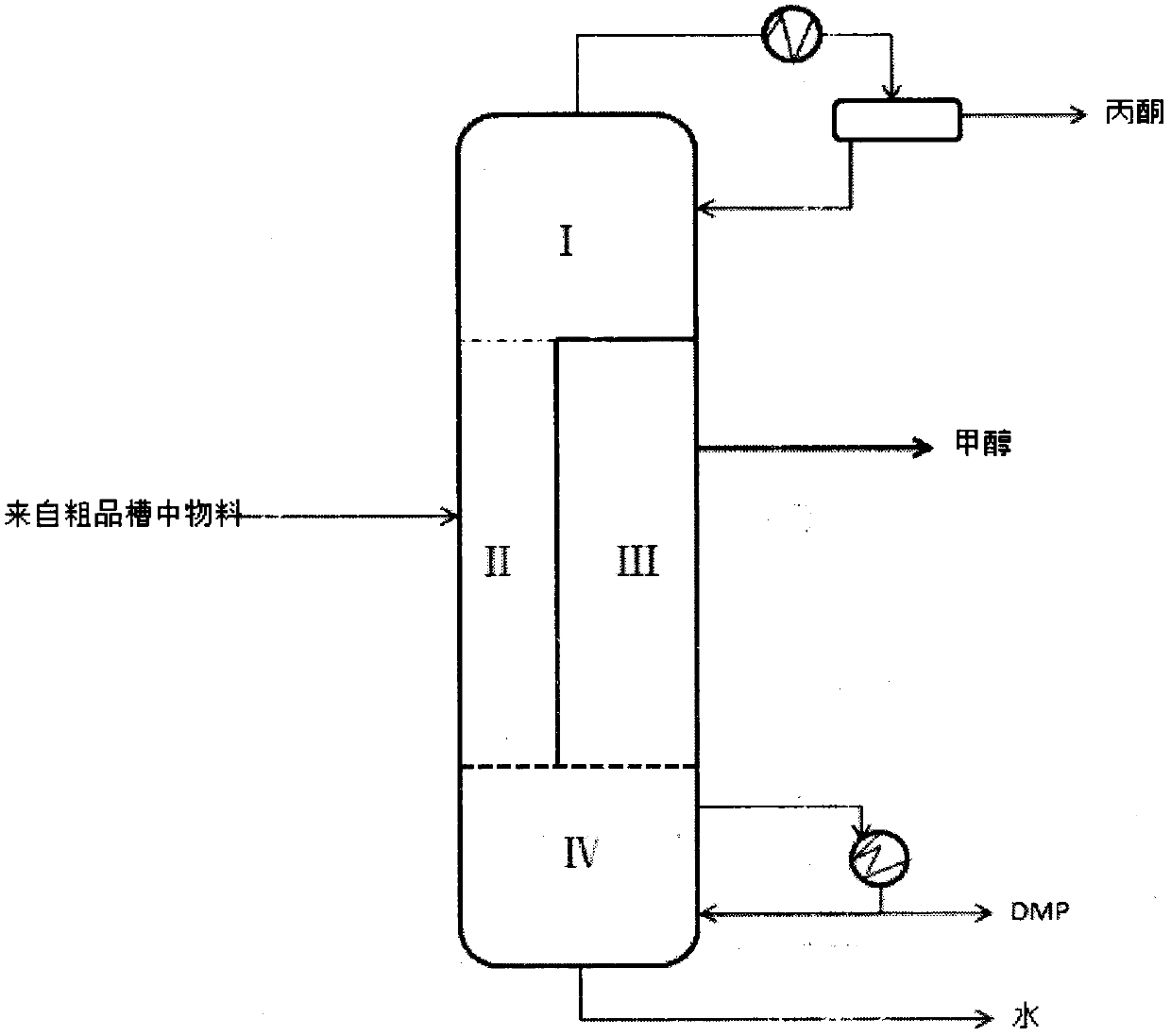

Image

Examples

Embodiment 1

[0027] 1) Methanol (A) and acetone (B) from the storage tank in the tank farm are pumped into the batching tank at a molar ratio of 3.5:1;

[0028] 2) The mixture of methanol and acetone in the batching tank is pumped into the built-in steam coil and the distillation still with a distillation tower; The temperature is ≤80°C, and a certain reflux ratio is controlled at the top of the tower; part of the material in the reflux condenser is refluxed into the still, and the rest is cooled to 45-50°C by the first-stage condenser, the first-stage heat exchanger and the post-step alkalizer The material coming out is heat-exchanged and cooled to 30-35°C, and the frozen brine in the secondary condenser is cooled to -15°C to -20°C, and then enters the alkylation reactor after cooling down; another part of methanol from the methanol metering tank (C ) and the outlet material from the primary condenser enter from the same inlet of the primary heat exchanger; the molar ratio of methanol (C)...

Embodiment 2

[0034] 1) Methanol (A) and acetone (B) from the storage tank in the tank farm are pumped into the batching tank at a molar ratio of 3.8:1;

[0035] 2) The mixture of methanol and acetone in the batching tank is pumped into the built-in steam coil and the distillation still with a distillation tower; The temperature is ≤80°C, and a certain reflux ratio is controlled at the top of the tower; part of the material in the reflux condenser is refluxed into the still, and the rest is cooled to 45-50°C by the first-stage condenser, the first-stage heat exchanger and the post-step alkalizer The material coming out is heat-exchanged and cooled to 30-35°C, and the frozen brine in the secondary condenser is cooled to -15°C to -20°C, and then enters the alkylation reactor after cooling down; another part of methanol from the methanol metering tank (C ) and the outlet material from the primary condenser enter from the same inlet of the primary heat exchanger; the molar ratio of methanol (C)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com