SBS modified emulsified asphalt based on high solid content SBS emulsion

A technology of emulsified asphalt and high solid content, which is applied to building components, building insulation materials, buildings, etc. It can solve the problems of not meeting the requirements of high-quality road maintenance, low solid content of evaporation residue, and low SBS content, and achieve recycling The solvent speed is fast, the surface activity is good, and the effect of increasing the solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

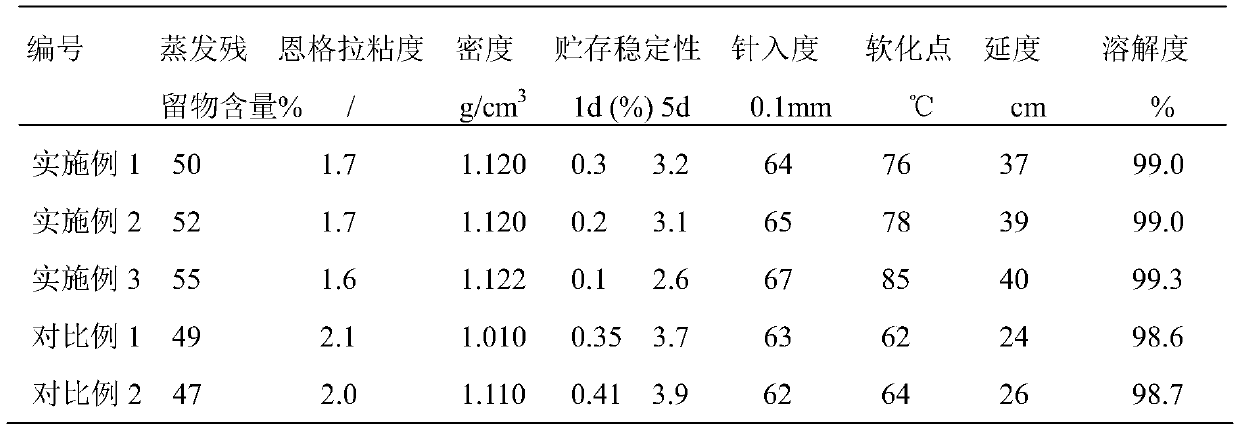

Examples

Embodiment 1

[0037] A kind of SBS modified emulsified asphalt based on high solid content SBS emulsion, its preparation method comprises the steps:

[0038] 1) Preparation of high solid content SBS emulsion: preparation of SBS solution: 50g SBS is dissolved in 160g cyclohexane solution, stirs and is configured into the SBS solution that mass concentration is 20%; Get 100g water, add 6g AC- wherein 181, 2g OP-10, 2g C 12 h 25 SO 4 Na, stirred evenly to form a compound emulsifier solution; the resulting emulsifier solution was sheared at a low speed (about 2000rpm) for 3min under a shear, and then slowly added to the prepared SBS solution, adding 0.1g flocculant styrene, Increase the rotation speed to about 8000rpm, and emulsify for 30 minutes; purify the emulsified SBS emulsion by vacuum distillation (pressure 84mmHg, temperature 45°C, time 8-12 hours), to obtain a high solid content SBS emulsion;

[0039] 2) The resulting high solid content SBS emulsion is emulsified in a colloid mill w...

Embodiment 2

[0042] A kind of SBS modified emulsified bitumen based on high solid content SBS emulsion, its preparation method comprises the steps: with embodiment 1 gained high solid content SBS emulsion and water, victory 90# matrix asphalt, AC-181 by 6:42:55 The mass ratio of :2 is emulsified in a colloid mill (the control speed is 15000r / min, and the time is 3min) to obtain SBS modified emulsified asphalt.

Embodiment 3

[0044] A kind of SBS modified emulsified asphalt based on high solid content SBS emulsion, its preparation method comprises the steps: the high solid content SBS emulsion of embodiment 1 gained and water, victory 90# matrix asphalt, AC-181 according to 7:41:55 The mass ratio of :2 is emulsified in a colloid mill (the control speed is 15000r / min, and the time is 3min) to obtain SBS modified emulsified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com