Method and device for selectively leaching scandium from laterite nickel ore smelting slag

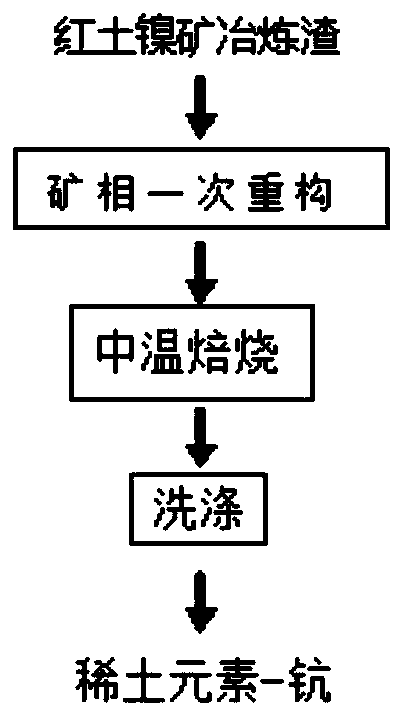

A technology for laterite nickel ore and smelting slag, applied in the field of selective leaching of scandium, which can solve the problem of low leaching rate of rare earth elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

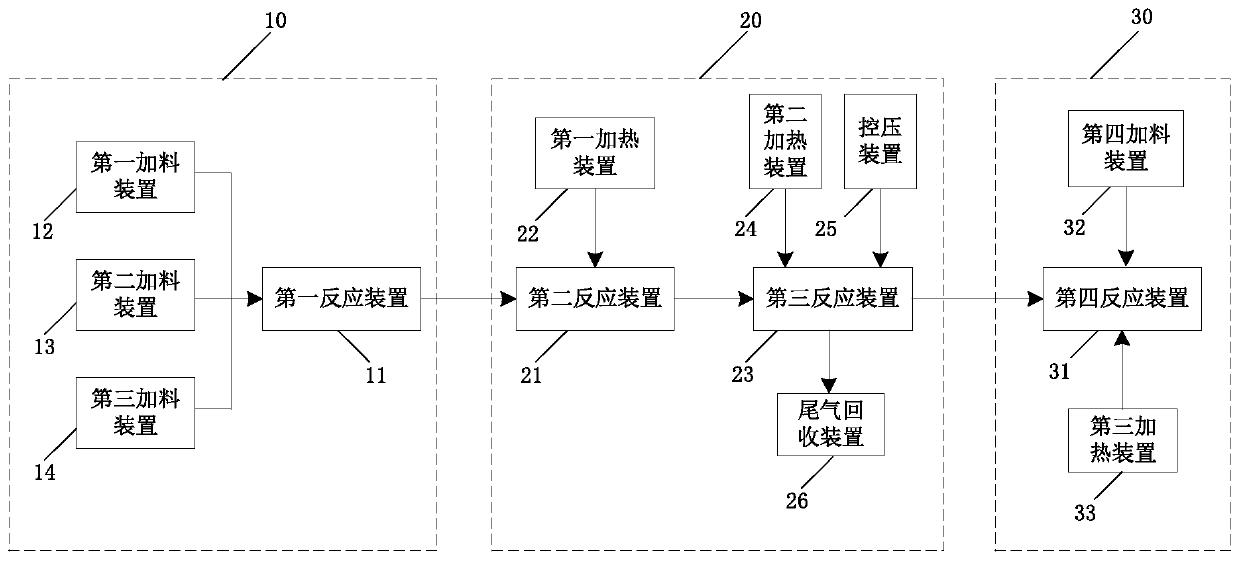

Method used

Image

Examples

Embodiment 1

[0069] The laterite nickel ore smelting slag or the first ore phase restructuring agent (9mol / L H 2 SO 4 ) in a ratio of 1g:1mL to obtain the reconstituted mineral acid salt. Complete the first reconstruction of ore phases in laterite nickel ore smelting slag.

[0070] Use laterite nickel ore smelting slag and the second ore phase reconstruction agent (0.1mol Na 2 SO 4 solution) at a dosage ratio of 1g:1mL, mix the reconstituted mineral acid salt with the second mineral phase reconstituter, then raise it from room temperature to 450°C at 10°C / min, and keep the temperature constant for 2h to carry out the second Refactoring process. Then the low-temperature roasted product was raised from 450°C to 650°C, and roasted at 650°C for 4 hours to reconstruct the ore phase of the lateritic nickel ore smelting slag for the third time to obtain a medium-temperature roasted product. After the calcination is completed, it is cooled to below 300°C with the furnace.

[0071] Under stir...

Embodiment 2

[0073] The laterite nickel ore smelting slag is mixed with the first mineral phase restructuring agent in a ratio of 1g:0.8mL to obtain the reconstructed mineral salt. The first mineral phase restructuring agent is analytically pure H 2 SO 4 Mixed solution with analytical pure HCl solution, the weight ratio is 5:1.

[0074] Raise the reconstituted mineral acid salt from room temperature to 450°C at 10°C / min, and roast at 450°C for 2 hours to perform a second reconstruction of the laterite nickel ore smelting slag phase to obtain a low-temperature roasted product.

[0075] The low-temperature roasted product was raised from 450°C to 680°C, and roasted at 680°C for 1 hour to reconstruct the ore phase of lateritic nickel ore smelting slag for the third time to obtain a high-temperature roasted product. After the roasting was completed, the high-temperature roasted product was The furnace is cooled to below 300°C.

[0076] Under stirring, wash the high-temperature roasted produc...

Embodiment 3

[0078] The difference from Example 1 is that the temperature of the medium-temperature roasting process is 400°C.

[0079] The leaching rate of rare earth scandium element is 85wt%, the leaching rate of iron element is 1.90wt%, the leaching rate of chromium element is less than 1wt%, the leaching rate of silicon element is less than 0.5wt%, and the leaching rate of aluminum element is less than 50wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com