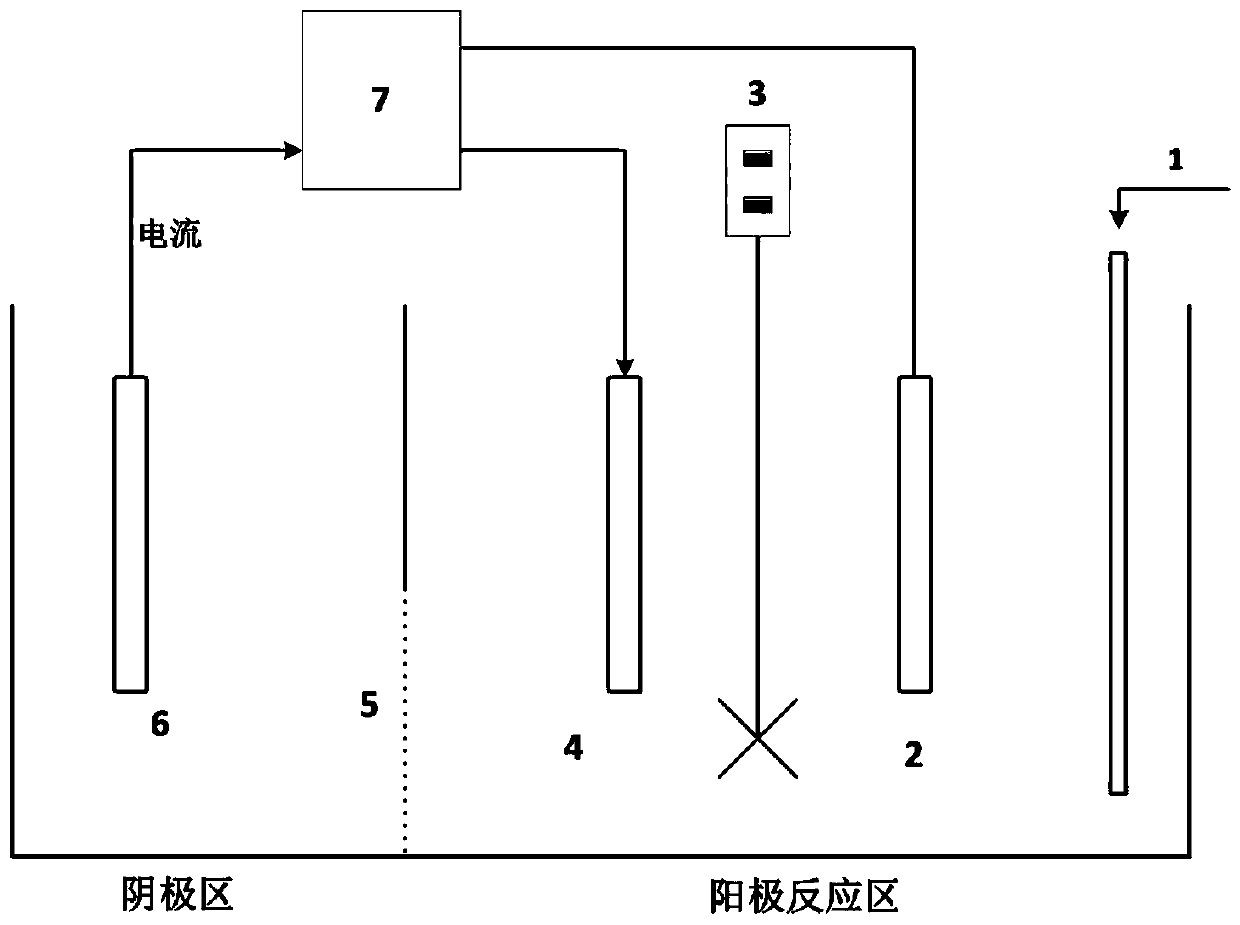

An electrochemical method and device for controlling bioleaching process

A bioleaching and electrochemical technology, applied in the direction of improving process efficiency, can solve problems such as excess acid and iron, low recovery rate of copper resources, and increased pressure on environmental protection, so as to reduce the production of acid iron and achieve selective leaching , reduce the effect of solution purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The ore used comes from a low-grade copper sulfide mine in Fujian. The copper in the ore mainly exists in the form of chalcocite and copper blue, the content of pyrite is relatively high, and the gangue minerals mainly exist in the form of silicate, and the acid consumption is low. The analysis results of the main elements of the ore are shown in Table 1.

[0046] Table 1 Chemical analysis results of main elements

[0047] Cu Fe S SiO 2

Content / wt% 0.35 3.52 3.81 79.28

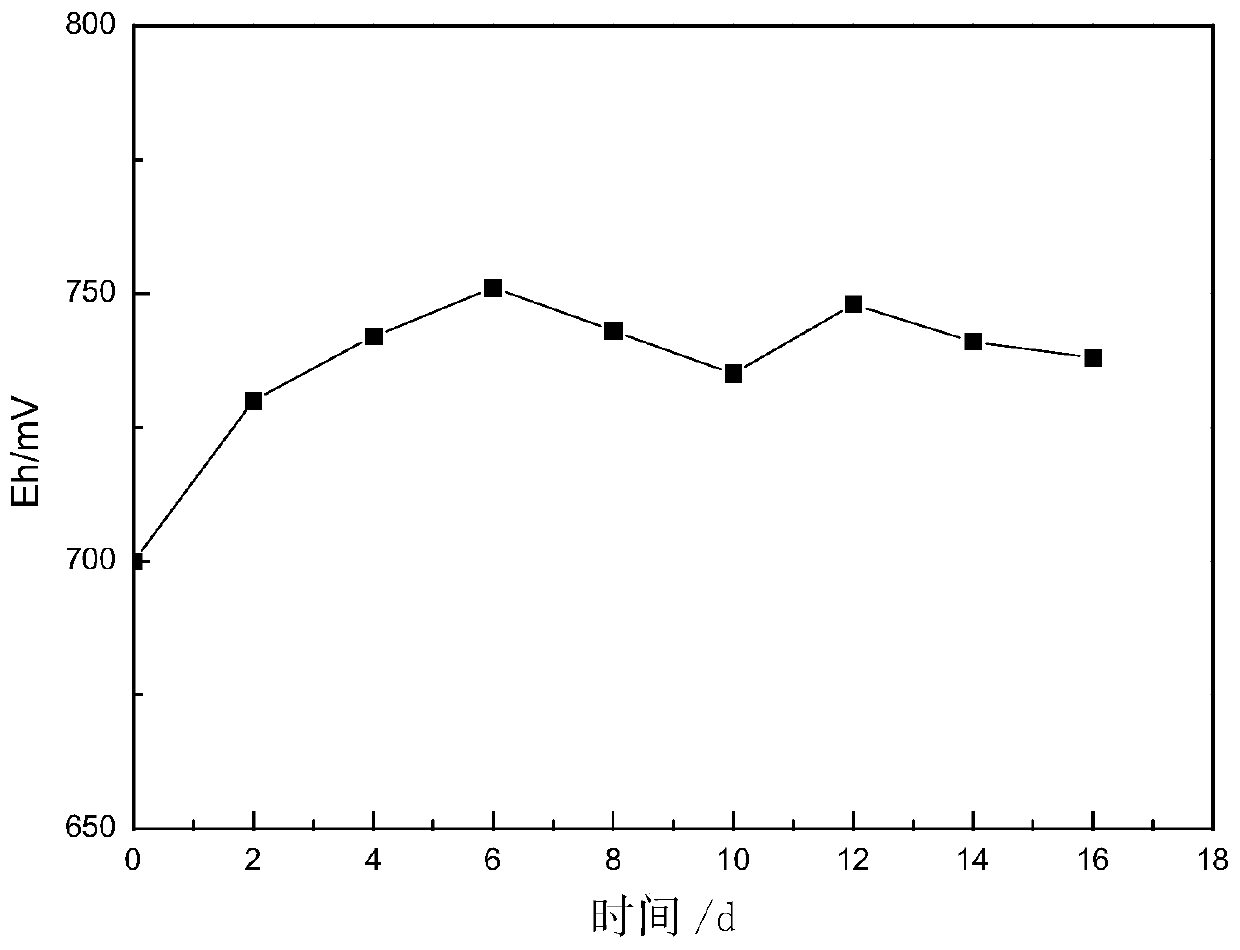

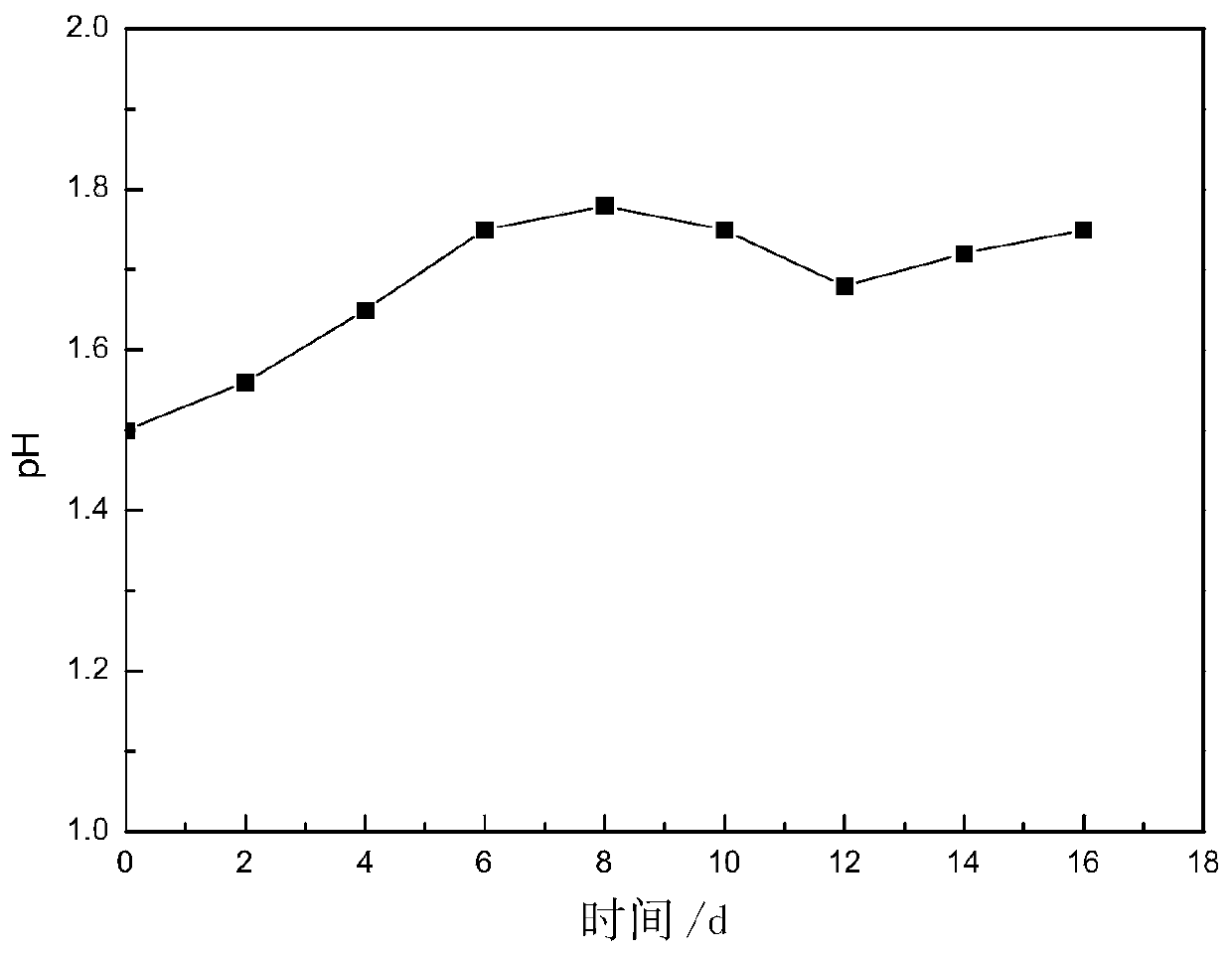

[0048] First add tap water to the electrochemical cell, use 20v / v% sulfuric acid to prepare acidic water with a pH value of 1.50 as the electrochemical reaction solution, add it to the anode area and the cathode reaction area, and then insert the cultured mixed bacteria into the cathode area, the inoculation amount 20% (v / v), then add -74 micron ore powder with a proportion of more than 80%, prepare the pulp concentration to 5% (w / w), and ventilate the air, the ventila...

Embodiment 2

[0053] The ore used comes from a low-grade copper sulfide mine in Xinjiang. The copper in the ore mainly exists in the form of chalcocite and chalcopyrite, the content of pyrite is relatively high, the gangue minerals mainly exist in the form of silicate, and the acid consumption is low. . The analysis results of the main elements of the ore are shown in Table 3.

[0054] Table 3 Chemical analysis results of main elements

[0055] Cu Fe S SiO 2

Content / wt% 0.45 3.61 3.71 80.12

[0056] First add tap water to the electrochemical cell, use 20v / v% sulfuric acid to prepare acidic water with a pH value of 1.50 as the electrochemical reaction solution, add it to the anode area and the cathode reaction area, and then insert the cultured mixed bacteria into the cathode area, the inoculation amount 20% (v / v), then add -74 micron ore powder with a proportion of more than 80%, prepare a pulp concentration of 5% (w / w), and ventilate, the ventilation rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com