A method for extracting arsenic from arsenic-containing nickel-cobalt slag and preparing arsenate

A technology of nickel-cobalt slag and arsenate, which is applied in the direction of arsenate/arsenite, chemical instruments and methods, arsenic compounds, etc., can solve the problems of high energy consumption, increased equipment investment costs, high energy consumption, etc., and achieve The effect of high leaching rate, low cost, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

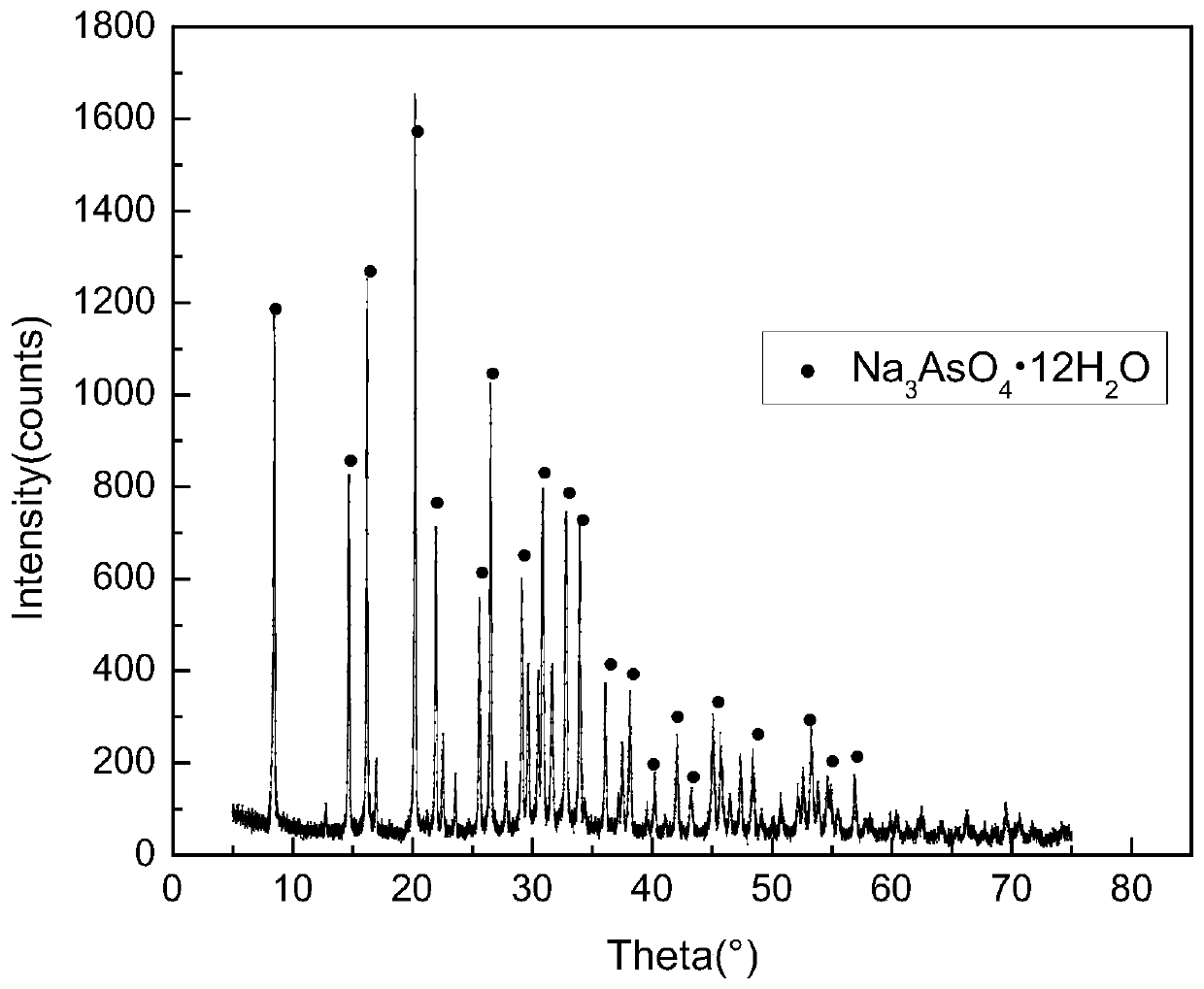

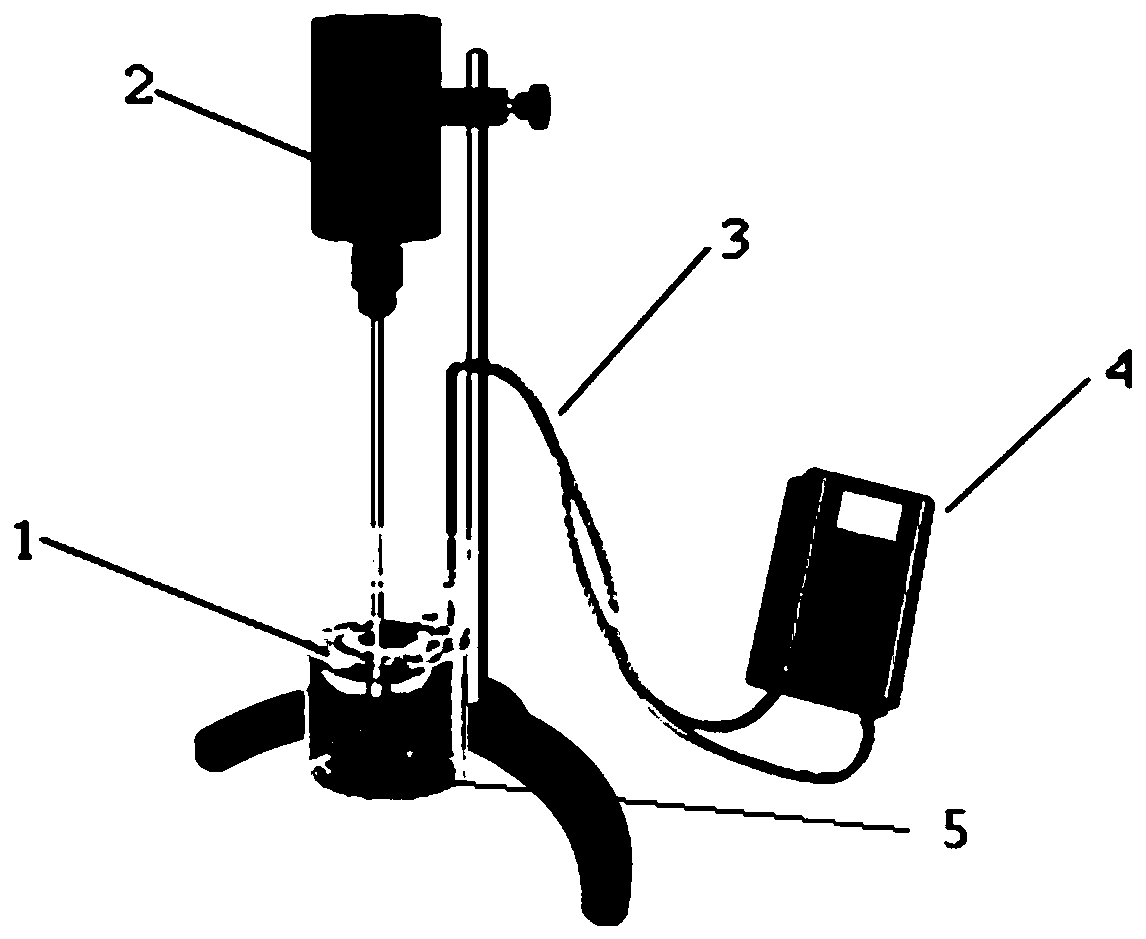

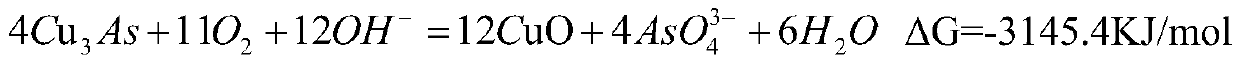

[0063] Add 60g of arsenic-containing nickel-cobalt slag material with a particle size of 1 μm to 300mL of 5M NaOH solution to form a mixed slurry, place the mixed slurry in a reactor, and heat the reactor in a water bath at 85°C; The bottom is provided with an intake ring pipe with a circumference of 15 cm. Six air holes are evenly distributed on the air intake ring pipe with a diameter of 3 mm. The air holes on the air intake ring pipe on the same cross-section are in the same shape as the horizontal plane of the bottom of the reaction vessel. 45°, the air is introduced into the reactor from the air hole, the flow rate of the air is 3.5L / min, and the stirring reaction is carried out at the speed of 250r / min by a paddle stirrer for 8 hours to realize the removal of arsenic-containing nickel-cobalt slag Oxidative alkali leaching; the obtained solid phase is copper-nickel-cobalt-enriched slag, and the liquid phase is zinc-arsenic-rich leaching solution. The main components of the...

Embodiment 2

[0065] Add 60 g of arsenic-containing nickel-cobalt slag materials with a particle size of 40 μm to 300 mL of 5M NaOH solution to form a mixed slurry, place the mixed slurry in a reactor, and heat the reactor in a water bath at 80 ° C; The bottom is provided with an intake ring pipe with a circumference of 15 cm. Six air holes are evenly distributed on the air intake ring pipe with a diameter of 3 mm. The air holes on the air intake ring pipe on the same cross-section are in the same shape as the horizontal plane of the bottom of the reaction vessel. 45°, the air is introduced into the reactor from the vent hole, and the flow rate of the air is 3.5L / min. Oxidative alkali leaching; the obtained solid phase is copper-nickel-cobalt-enriched slag, and the liquid phase is zinc-arsenic-rich leaching solution. The main components of the leaching solution are sodium arsenate and sodium zincate. The arsenic-containing leaching solution is evaporated and crystallized to obtain arsenic ac...

Embodiment 3

[0067] Add 60 g of arsenic-containing nickel-cobalt slag materials with a particle size of 40 μm to 300 mL of 5M NaOH solution to form a mixed slurry, place the mixed slurry in a reactor, and heat the reactor in a water bath at 85 ° C; The bottom is provided with an intake ring pipe with a circumference of 15 cm. Six air holes are evenly distributed on the air intake ring pipe with a diameter of 3 mm. The air holes on the air intake ring pipe on the same cross-section are in the same shape as the horizontal plane of the bottom of the reaction vessel. 45°, the air is introduced into the reactor from the air hole, the flow rate of the air is 3.5L / min, and the stirring reaction is carried out at the speed of 250r / min by a paddle stirrer for 8 hours to realize the removal of arsenic-containing nickel-cobalt slag Oxidative alkali leaching; the obtained solid phase is copper-nickel-cobalt-enriched slag, and the liquid phase is zinc-arsenic-rich leaching solution. The main components ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com