Production method of water-soluble hydroxyethyl cellulose

一种羟乙基纤维素、制造方法的技术,应用在纤维素纸浆后处理改性、纸浆性质改性等方向,能够解决数量减少、难以表现出水溶性、平均加成摩尔数降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the production of the target hydroxyethyl cellulose, the obtained basic cellulose is reacted with ethylene oxide. Here, alkaline cellulose and ethylene oxide are charged into a reaction container, and the reaction is performed while stirring them. At this time, the reaction solvent may be put into the reaction container at the same time, and the alkali cellulose and ethylene oxide may be reacted in the reaction solvent. Using a reaction solvent can promote the uniform reaction of each glucose unit of alkaline cellulose and ethylene oxide.

[0036] The amount of ethylene oxide used is controlled so that in the produced hydroxyethyl cellulose, the average number of added moles of ethylene oxide per glucose unit reaches 0.1 to 1.0 moles (more than 0.1 moles and 1.0 moles the following). In particular, in a preferred aspect of the production method, control is performed so that the above-mentioned average added mole number of ethylene oxide becomes 0.1 mol or more and ...

Embodiment

[0053] Hereinafter, although an Example, a comparative example, etc. are given and this invention is demonstrated concretely, this invention is not limited by these Examples etc. at all.

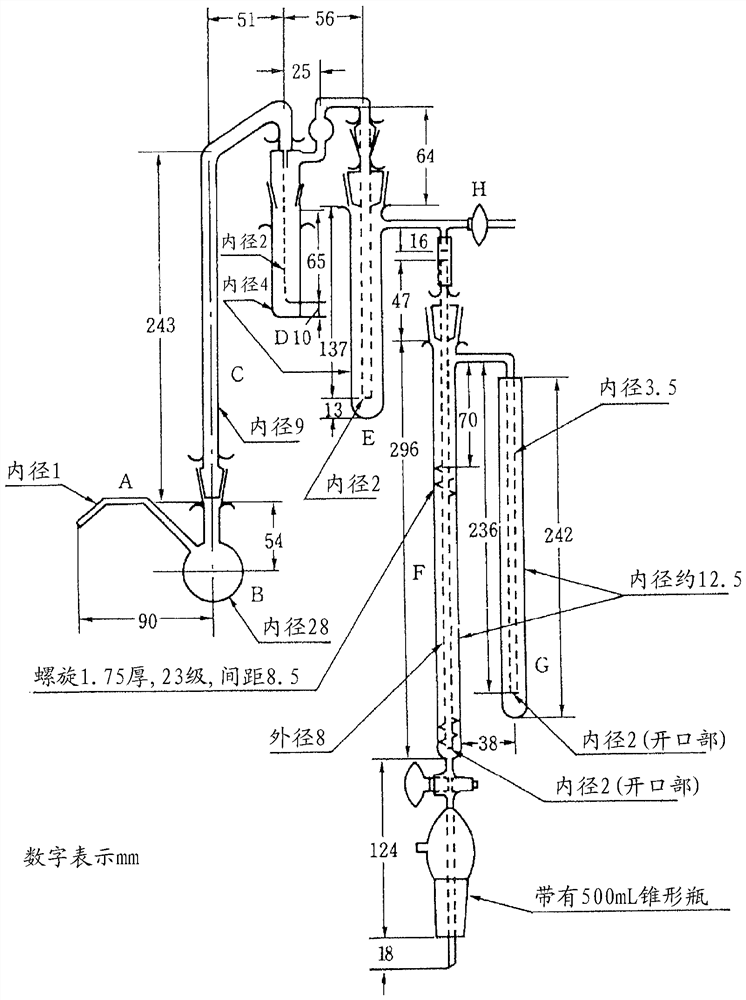

[0054] In the Examples, etc., the average number of added moles of ethylene oxide per glucose unit of hydroxyethyl cellulose is supervised by the Ministry of Health, Welfare and Pharmaceutical Affairs Bureau of Japan, Standards for Pharmaceutical Additives 1993, Yaoji Daily Co., Ltd., 250 items - Items necessary for the measurement of the device described in Item 254 "Hydroxyethyl Cellulose, Quantitative Method" are calculated from these measurement items. Specifically, it is as follows. It should be noted that A to H in the following description are diagrams of the above-mentioned device described in the above-mentioned Pharmaceutical Additives Standard 1993 ( figure 1 ) mark symbol.

[0055] 0.075 g (a) of hydroxyethylcellulose dried at 105 degreeC for 2 hours was put into the decomposit...

Embodiment 1

[0077] 150 g of wet cake-like alkaline cellulose obtained in the production example, 3.5 g of ethylene oxide, and 50 g of methyl isobutyl ketone were charged into a kneader with a volume of 1 L while controlling the temperature to 15° C. Stir and mix at this temperature for 30 minutes. Next, the temperature was raised to 50° C. while heating while stirring and mixing was continued, and the basic cellulose and ethylene oxide were reacted for 3 hours.

[0078] The wet cake obtained by filtering off the reactant in the kneader was washed with a washing solvent composed of 100 g of methyl isobutyl ketone, 100 g of methanol, and 50 g of water. Further, the wet cake was further washed and neutralized with 50 g of a neutralization solvent prepared by adding 2 g of acetic acid to a washing solvent of the same composition to obtain 180 g of a neutralized wet cake. Then, this neutralized wet cake was dried to obtain 50 g of hydroxyethylcellulose.

[0079] Next, the obtained hydroxyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com