Hydrogen sulfide sustained-release dressing and manufacturing method thereof

A manufacturing method, hydrogen sulfide technology, applied in medical science, bandages, etc., can solve the problems of cell apoptosis or inflammation, cell toxicity, hydrogen sulfide toxicity, etc., and achieve the effect of promoting healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

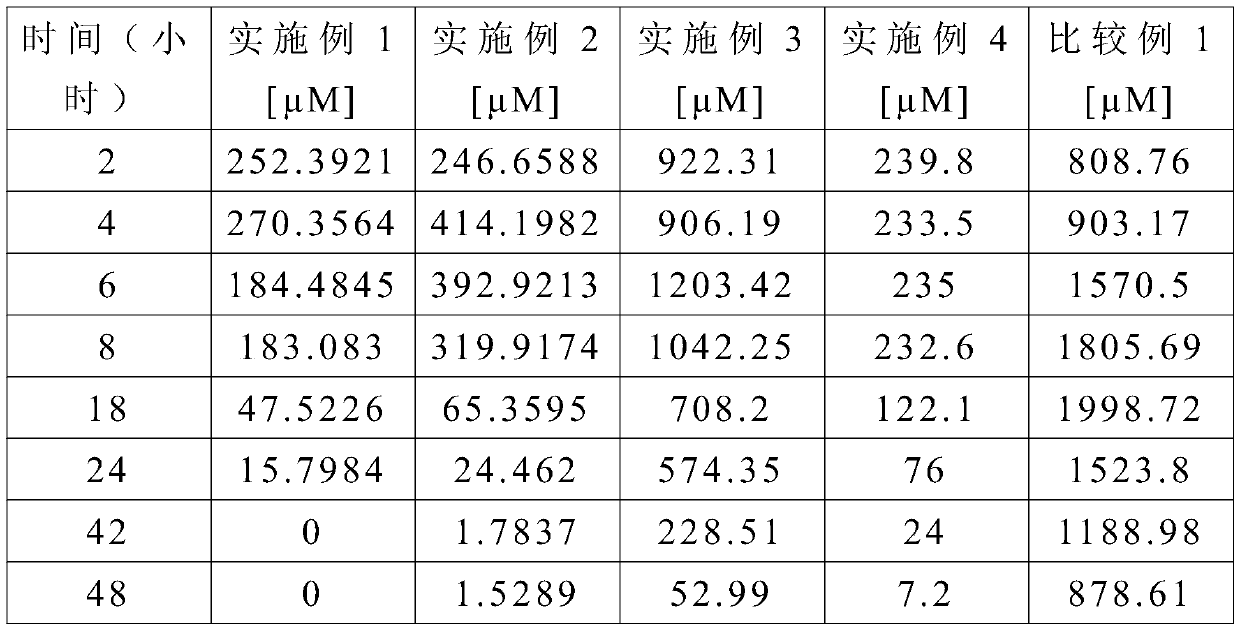

Examples

Embodiment 1

[0043] Get 15.4 grams of styrene-isoprene-styrene (SIS) copolymer (Kraton D1161, purchased from Kraton, the U.S.), 36.55 grams of C9 modified resin (Wingtack 86, purchased from CRAY VALLEY, the U.S.), 6.4 gram of mineral oil (Kaydol white mineral oil purchased from Sonneborn, the U.S.) and 1 gram of hindered phenol tetrakis (3,5-di-tert-butyl-4-hydroxyl) pentaerythritol phenylpropionate (Chinox 1010, purchased from Double Bond Chemicals , Taiwan) stirred at 180° C. under nitrogen atmosphere for 60 minutes, then cooled to 120° C., added 40 grams of sodium carboxymethylcellulose, 0.5 grams of surfactant Tween 80 and 0.15 grams of sodium hydrosulfide, stirred for 10 Minutes later, it is poured into a mold and heat-pressed at 90°C to form a hydrogen sulfide sustained-release dressing.

Embodiment 2

[0045] The steps and materials of Example 2 are the same as in Example 1, except that 36.5 g of C9 modified resin is used instead of 36.55 g of C9 modified resin and 0.2 g of sodium hydrosulfide is used instead of 0.15 g of sodium hydrosulfide.

Embodiment 3

[0047] The steps and materials of Example 3 are the same as in Example 1, except that 15.3 grams of styrene-isoprene-styrene (SIS) copolymer is used instead of 15.4 grams of styrene-isoprene-styrene (SIS) Copolymer, replacing 36.55 grams of C9 modified resin with 36.3 grams of C9 modified resin and replacing 0.15 grams of sodium hydrosulfide with 0.5 grams of sodium hydrosulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com