Formula of wear-resistant and oxidation-resistant hydraulic oil composite agent and preparation process thereof

A preparation process and technology of hydraulic oil, applied in the field of lubricating oil, can solve problems such as large differences in the quality of hydraulic oil, and achieve the effects of good cleaning and dispersing performance, good compatibility and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

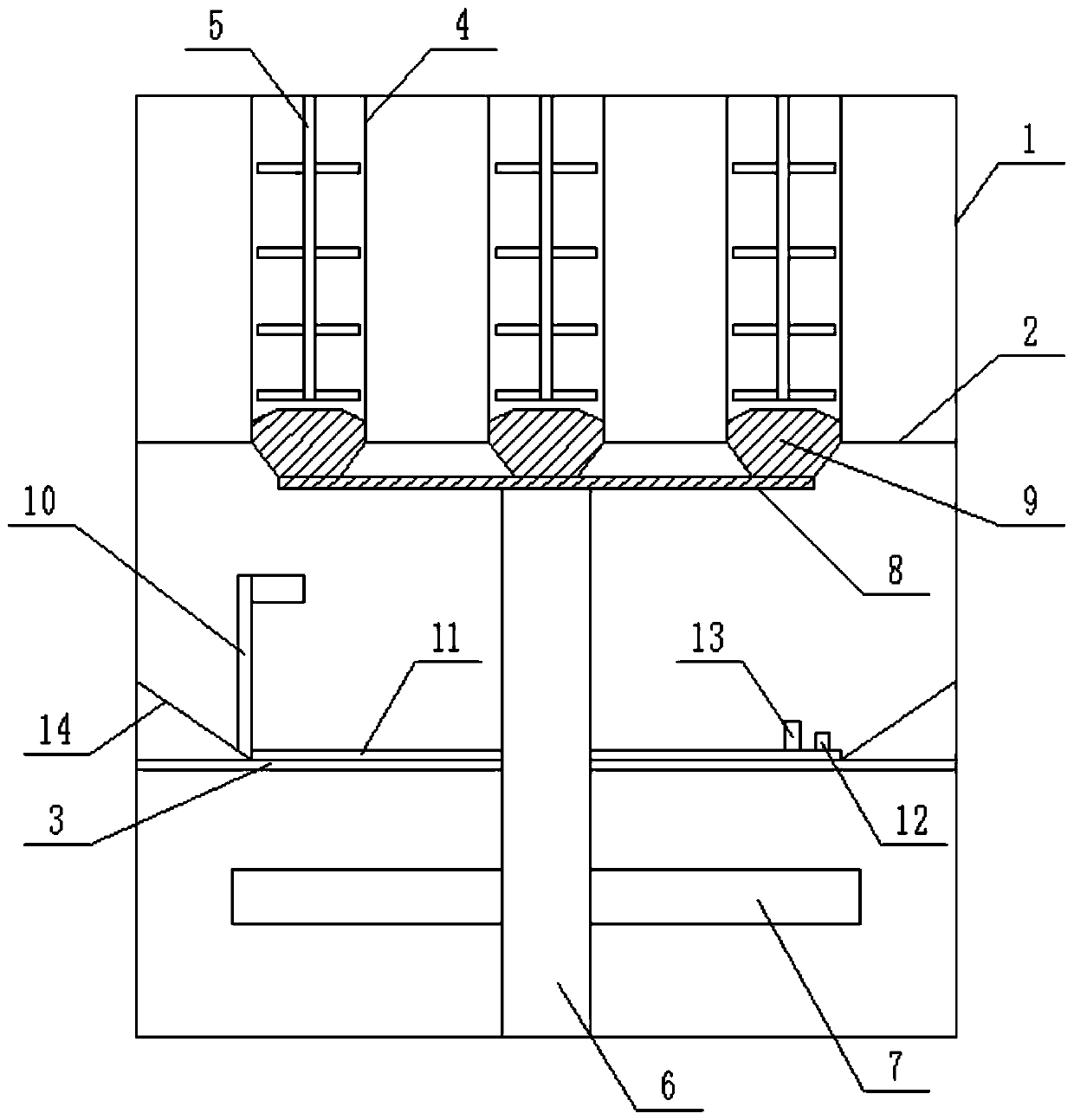

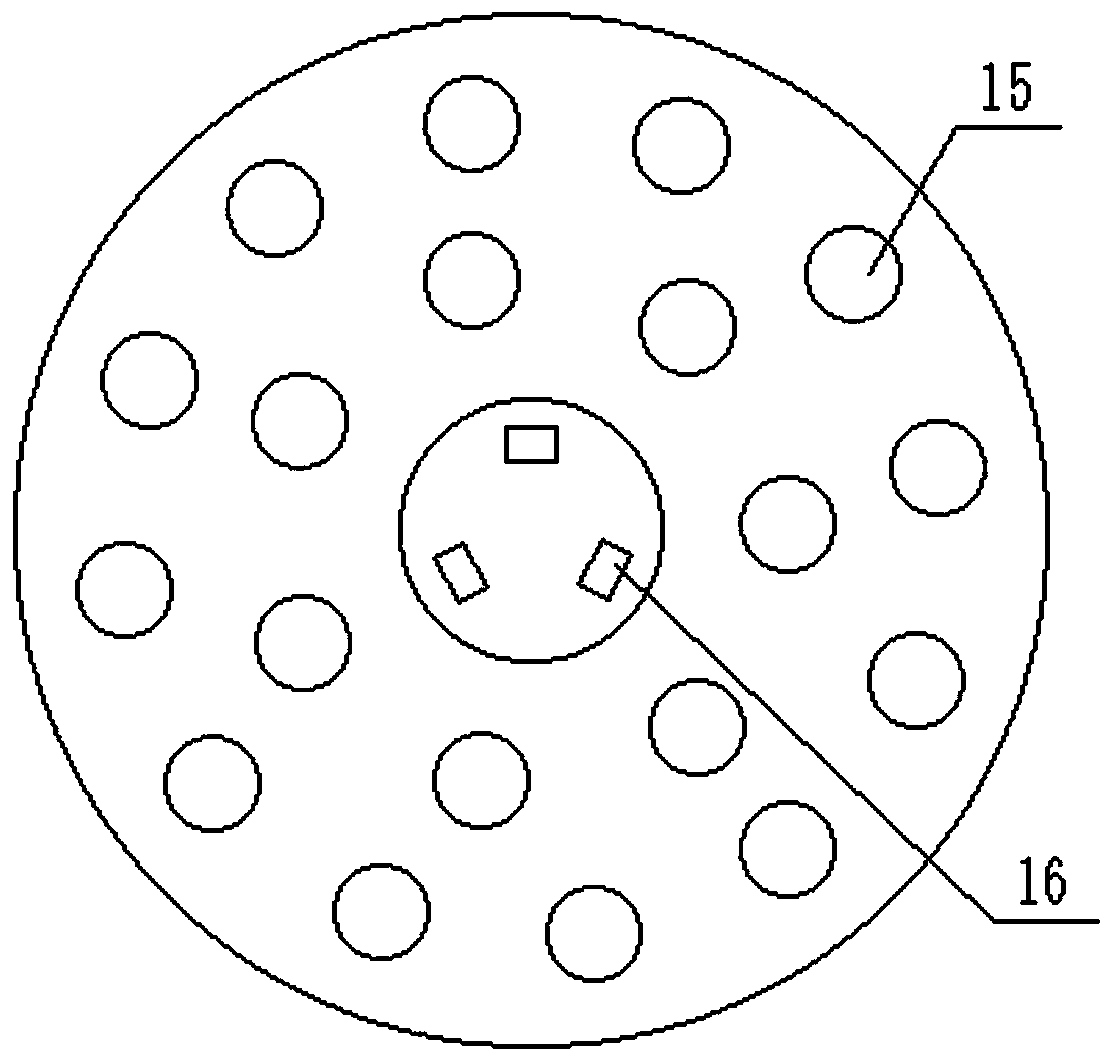

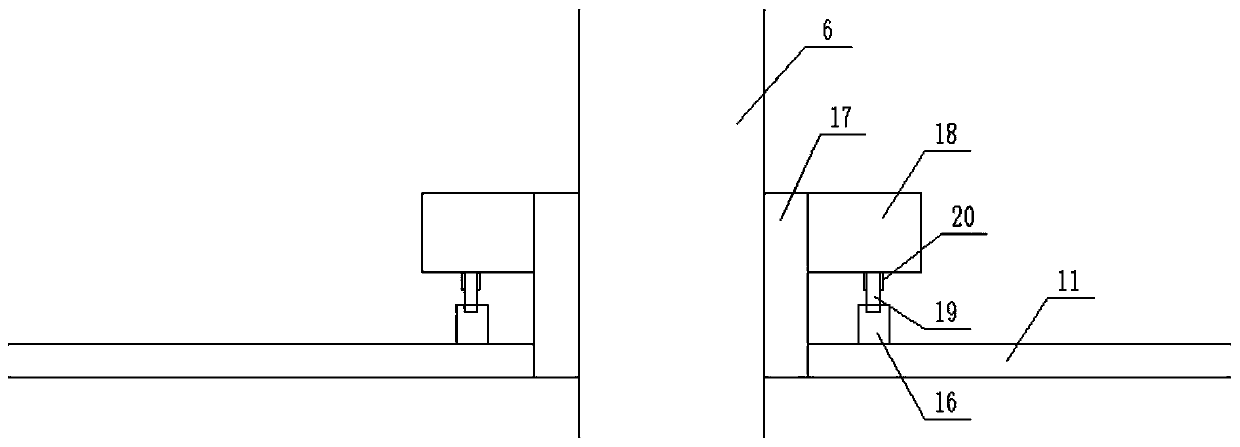

Image

Examples

Embodiment 1

[0034] The components of the hydraulic oil compound formulation are calculated by mass percentage: long-chain primary alcohol dialkyl zinc dithiophosphate 20%, di-tert-butyl p-cresol 10%, alkylated diphenylamine 10%, tricresol phosphate Esters 15%, High Base Number Synthetic Calcium Sulfonate 8%, Dipolyisobutylene Diimide 5%, Dodecenyl Succinate Half Ester 1%, Basic Dinonylnaphthalene Barium Sulfonate 4%, Benzene Tris 1.5% azole octadecylamine salt, supplemented by low-viscosity II base oil. The preparation process is as follows: adding each component into a reaction kettle according to its mass percentage, raising the temperature to 75°C, stirring evenly and cooling.

[0035] The above-mentioned composite agent formula is added to 98% of the second-class base oil according to the mass percentage of 2%, and the temperature is raised to 55°C in the reaction kettle, stirred evenly and cooled, and the prepared hydraulic oil has high anti-wear performance, the maximum No jamming ...

Embodiment 2

[0038] The components of the hydraulic oil compound formulation are calculated by mass percentage: 10% of long-chain primary alcohol dialkyl zinc dithiophosphate, 10% of di-tert-butyl p-cresol, 8% of alkylated diphenylamine, and tricresyl phosphate Esters 20%, High Base Number Synthetic Calcium Sulfonate 5%, Dipolyisobutylene Diimide 5%, Dodecenyl Succinate Half Ester 1%, Basic Dinonylnaphthalene Barium Sulfonate 4%, Benzene Tris 1.5% azole octadecylamine salt, supplemented by low-viscosity II base oil. The preparation process is as follows: adding each component into a reaction kettle according to its mass percentage, raising the temperature to 75°C, stirring evenly and cooling.

[0039] The above-mentioned composite agent formula is added to 98% of the second-class base oil according to the mass percentage of 2%, and the temperature is raised to 55°C in the reaction kettle, stirred evenly and cooled, and the prepared hydraulic oil has high anti-wear performance, the maximum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com