Segment support construction method for beam bridge

A construction method and segment technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high requirements for construction equipment, troublesome construction, poor connection strength, etc., and achieve the convenience and safety of workers and transportation. and safety, avoid inconvenience and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the first embodiment, a three-span prestressed concrete continuous beam bridge is taken as an example. A method for segmental support construction of a beam bridge has the following technical solutions:

[0037] The first step is to collect detailed engineering quality, water temperature geology and foundation design materials, consider the load size, topography, soil structure, soil conditions, surrounding environment, groundwater characteristics, adjacent buildings and other factors, and select foundation treatment Method, the foundation is hardened so that its bearing capacity and stability are sufficient to bear the dead weight load of the superstructure transmitted by the support.

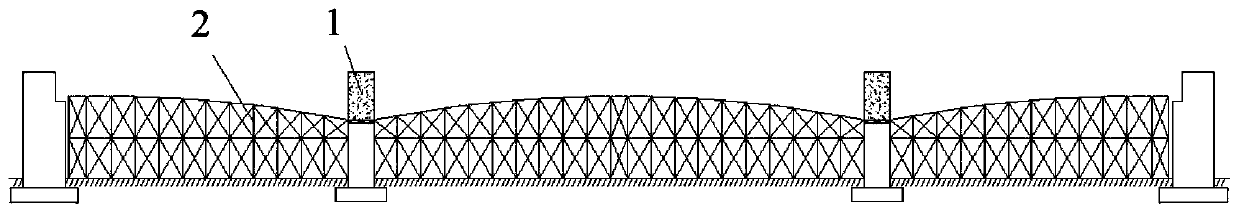

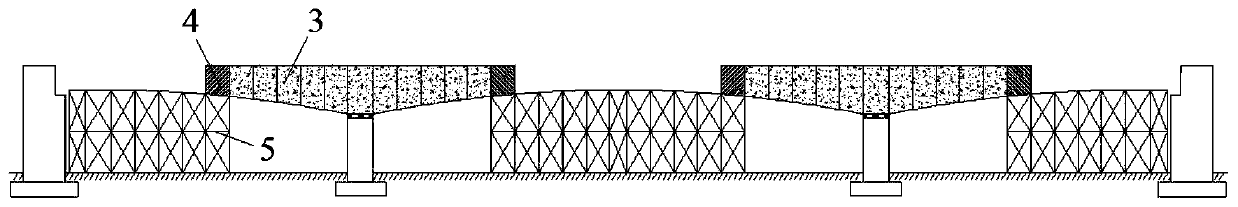

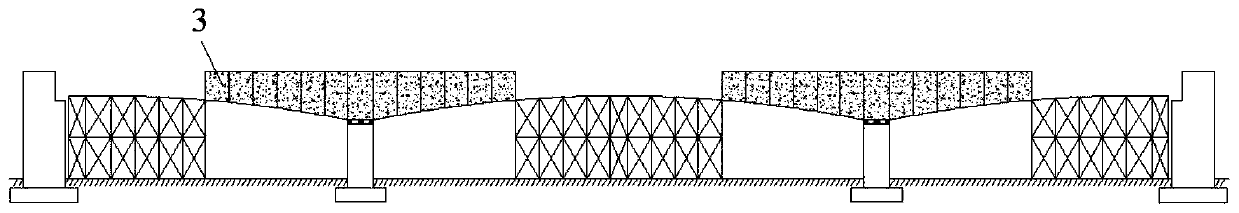

[0038] The second step is to install the bracket. See figure 1 , Use bracket cast-in-place construction starting zero block 1. According to the direction of the beam bridge, accurately release the erection range and vertical and horizontal spacing of the bracket 2 and clean the nearby gr...

Embodiment 2

[0044] In the second embodiment, a three-span prestressed concrete continuous box girder bridge with corrugated steel webs is taken as an example. A method for segmental bracket construction of a girder bridge has the following technical solutions:

[0045] The first step is to harden the foundation. Its bearing capacity and stability are sufficient to bear the self-weight load of the superstructure transmitted by the bracket.

[0046] The second step is to install the bracket. See Picture 8 , Use bracket cast-in-place construction to start zero block 1. According to the direction of the beam bridge, accurately release the erection range and vertical and horizontal spacing of the bracket 2 and clean the nearby ground surface. Check the strength and stability of the bracket 2, and the calculation result should meet the requirements of the specification. Between the bridge piers and between the bridge piers and abutments, all supports 2 are arranged. Each support pole is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com