Foundation treatment apparatus and method with hardener filling in electro-osmosis process

A foundation treatment and curing agent technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of uneven soil reinforcement, excessive interface resistance, and limited engineering applications, and achieves improved water migration rate, improved Soil strength, effect of increasing effective stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

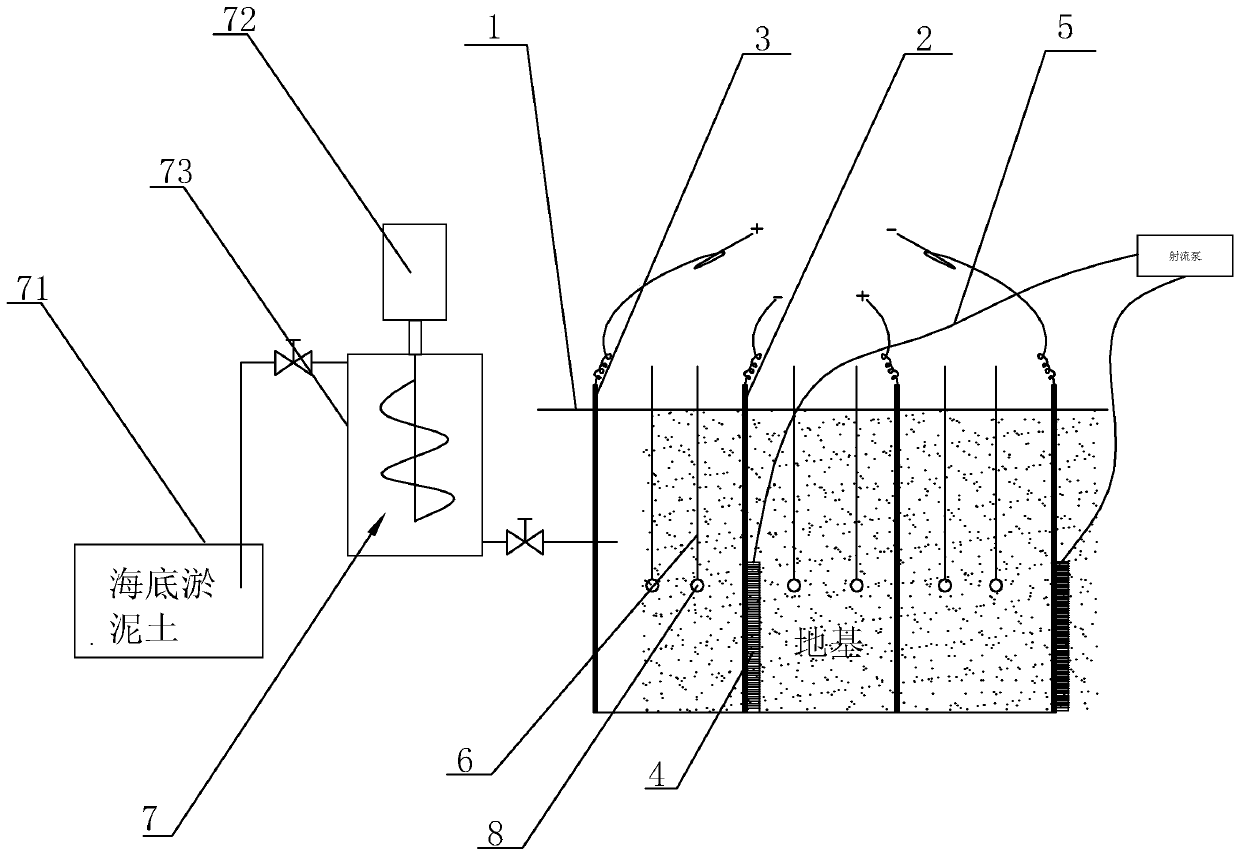

[0024] Refer to attached figure 1 A ground treatment method and a ground treatment device embodiment of filling a curing agent in the electroosmotic process of the present invention will be further described in detail.

[0025] A ground treatment method for filling a curing agent in an electroosmosis process, comprising the following steps:

[0026] (1) Transport the prepared ferric chloride flocculant into the blow-fill pipeline, then blow the flocculation blow-fill into the foundation, let it stand for a period of time, and then level the foundation, in order to better flocculate The dredging fill is blown into the foundation, the ferric chloride flocculant can be sucked into the pipeline by the mud pump, the flocculant and the soil are rotated and stirred by the blade fan in the pipeline, and then transported and blown into the foundation.

[0027] (2), on the foundation that needs to be treated, lay a layer of woven cloth 1, and mark the woven cloth 1, and insert the nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com