An external heat absorber structure for a tower photothermal power generation system

A technology of photothermal power generation and heat absorber, which is applied in solar thermal power generation, solar heating system, solar collector and other directions, can solve the problem of low optical efficiency of mirror field, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

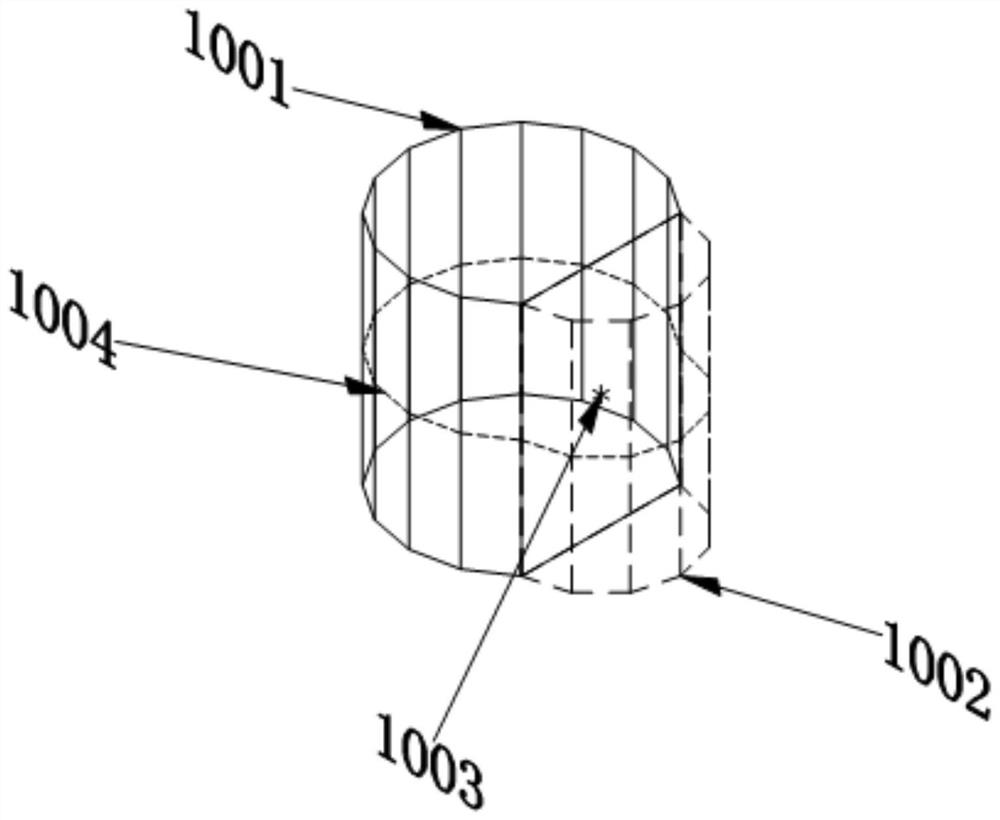

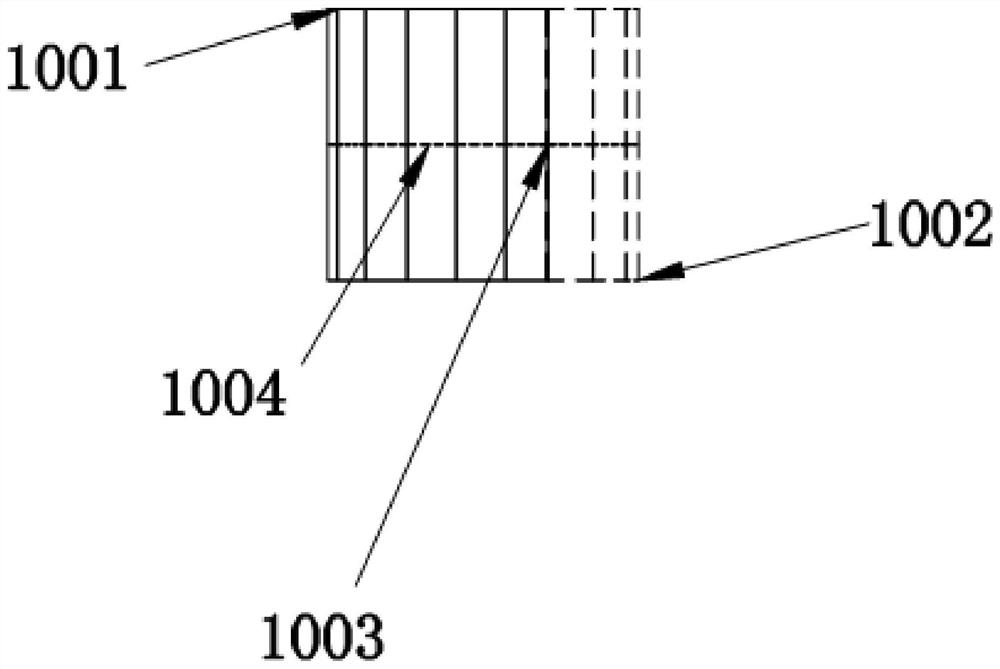

[0045] see figure 1 and figure 2 , an external heat absorber structure for a tower-type photothermal power generation system, including the light receiving surface of the first heat absorbing part 1001 and the second heat absorbing part 1002 is an arc surface, and the light receiving area of the first heat absorbing part 1001 is larger than The second heat absorbing part 1002, the first heat absorbing part 1001 and the second heat absorbing part 1002 cooperate to form a heat absorber, and the heat absorber is arranged on the heat absorbing tower. When the tower-type photothermal power generation system is located in the northern hemisphere, the first heat absorbing part 1001 is a heat absorber on the north side, and the second heat-absorbing part 1002 is a heat absorber on the south side; when the tower-type photothermal power generation system is located in the southern hemisphere, the first The heat absorbing part 1001 is a south heat absorber, and the second heat absor...

Embodiment 2

[0047] This embodiment is further limited on the basis of Embodiment 1, and other parts are the same as or similar to Embodiment 1, and will not be repeated here.

[0048] see figure 1 and figure 2 , a heat absorber for a tower-type photothermal power generation system, the diameter of the first heat absorption part 1001 is larger than the diameter of the second heat absorption part 1002, and the light receiving height of the first heat absorption part 1001 is the same as that of the second heat absorption part 1002 The light-receiving heights are the same, the arc of the first heat absorbing portion 1001 is greater than 180°, and the arc of the second heat absorbing portion 1002 is equal to 180°.

Embodiment 3

[0050] This embodiment is further limited on the basis of Embodiment 1, and other parts are the same as or similar to Embodiment 1, and will not be repeated here.

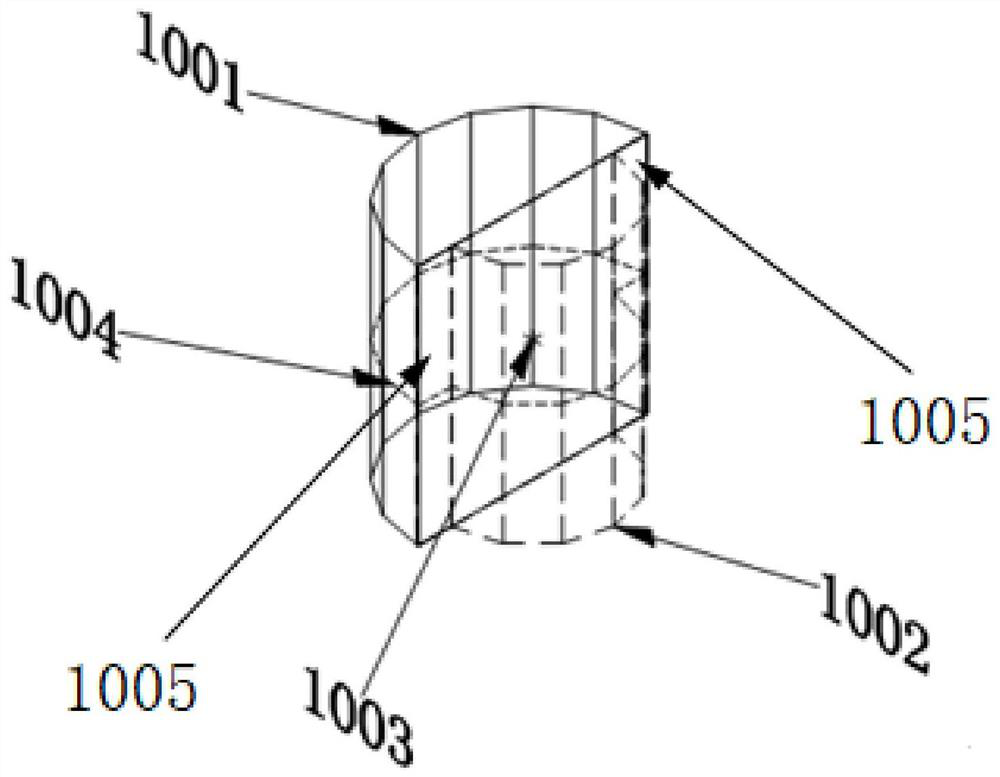

[0051] see image 3 and Figure 4 , a heat absorber for a tower-type photothermal power generation system, the diameter of the first heat absorption part 1001 is larger than the diameter of the second heat absorption part 1002, and the light receiving height of the first heat absorption part 1001 is the same as that of the second heat absorption part 1002 The light-receiving height is the same, the arc of the first heat absorbing part 1001 and the second heat absorbing part 1002 are equal to 180°, and the center of the arc of the first heat absorbing part 1001 and the center of the arc of the second heat absorbing part 1002 are located at The heat absorption tower center 1003 , the first heat absorption part 1001 and the second heat absorption part 1002 are connected through a planar heat absorption panel 1005 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com