Desulfurization catalysts efficacy detecting method

A desulfurization catalyst and detection method technology, applied in the field of detection and analysis, can solve the problems of poor quality representation, inability to measure product quality accurately, truly and effectively, and large differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

[0017] A method for detecting the effectiveness of a desulfurization catalyst, comprising the following steps,

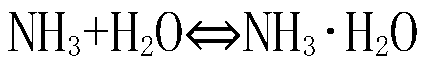

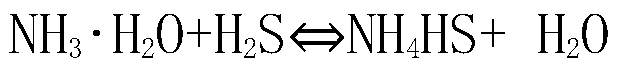

[0018] Step 1. After preparing the reagents and instruments required for testing the samples, prepare two desulfurization solutions, namely blank desulfurization solution and catalyst desulfurization solution.

[0019] Step 2, desulfurization detection test of desulfurization liquid standard gas. Put the standard gas containing the nominal value into the absorption bottles of blank desulfurization liquid and catalyst desulfurization liquid respectively. Air is introduced to make it regenerated, and the absorption bottle of the other catalyst desulfurization liquid is not injected with air for standby.

[0020] Step 3, detect respectively, calculate the parameter that characterizes desulfurization and decyanation cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com