Refining method and system of medical intermediate

A refining method and refining system technology, applied in the field of refining methods and systems of pharmaceutical intermediates, can solve problems such as lack of standardization of process operations, difficulty in product quality control, lack of standard operating procedures, etc., to avoid inconsistent product quality, Control product quality and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for refining a pharmaceutical intermediate, comprising the following steps:

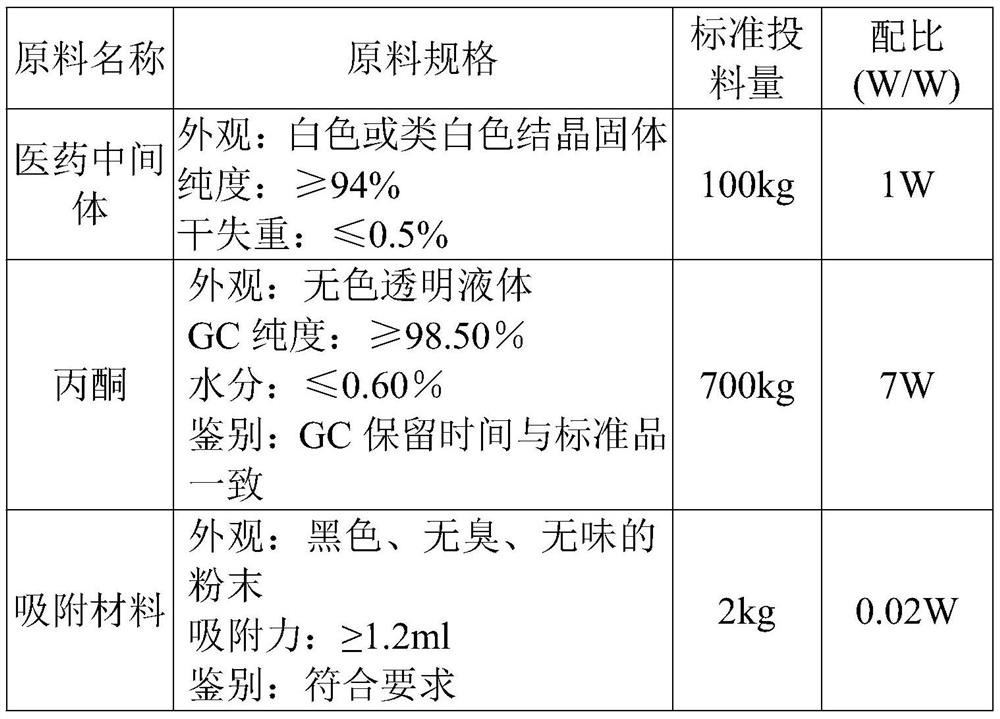

[0028] 1. Preparation before feeding: Check whether the equipment is running normally, whether the pipeline is smooth, and there is no foreign matter in the tank. Prepare all raw and auxiliary materials according to the amount of feeding. The specifications and proportions of the raw materials used are shown in Table 1. Check whether they are qualified Certificate, and two people to check, everything is normal before feeding.

[0029] 2. Decolorization: pump 700kg of acetone into the decolorization tank, open the tank cover, put in 100kg of pharmaceutical intermediates, and then put in 2kg of activated carbon, cover the tank cover, turn on the steam in the jacket, stir and reflux for 1 hour for decolorization;

[0030] 3. Filtration: Check the filter pipe and filter, lay out the filter bag and filter paper, vacuum filter the system to the concentration kettle, and pre-clean the decolo...

Embodiment 2

[0035] A method for refining a pharmaceutical intermediate, comprising the following steps:

[0036] 1. Preparation before feeding: Check whether the equipment is running normally, whether the pipeline is smooth, and there is no foreign matter in the tank. Prepare all raw and auxiliary materials according to the amount of feeding. The specifications and proportions of the raw materials used are shown in Table 1. Check whether they are qualified Certificate, and two people to check, everything is normal before feeding.

[0037] 2. Decolorization: pump 700kg of acetone into the decolorization tank, open the tank cover, put in 100kg of pharmaceutical intermediates, and then put in 2kg of activated carbon fiber, cover the tank cover, turn on the steam in the jacket, stir and reflux for 1 hour for decolorization;

[0038] 3. Filtration: Check the filter pipe and filter, lay out the filter bag and filter paper, vacuum filter the system to the concentration kettle, and pre-clean the ...

Embodiment 3

[0043] A method for refining a pharmaceutical intermediate, comprising the following steps:

[0044] 1. Preparation before feeding: Check whether the equipment is running normally, whether the pipeline is smooth, and there is no foreign matter in the tank. Prepare all raw and auxiliary materials according to the amount of feeding. The specifications and proportions of the raw materials used are shown in Table 1. Check whether they are qualified Certificate, and two people to check, everything is normal before feeding.

[0045] 2. Decolorization: pump 700kg of acetone into the decolorization tank, open the tank cover, put in 100kg of pharmaceutical intermediates, and then put in 2kg of zeolite, cover the tank cover, turn on the steam in the jacket, stir and reflux for 1 hour for decolorization;

[0046] 3. Filtration: Check the filter pipe and filter, lay out the filter bag and filter paper, vacuum filter the system to the concentration kettle, and pre-clean the decolorization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com